23 |

P a g e

LEAK TEST

Although all gas connections on the grill are leak tested at the factory prior to shipment,

a complete gas tightness check must be performed after assembly to ensure fittings were

not damaged after leaving the factory. Periodically check the entire system for leaks

following the procedures listed below.

BEFORE TESTING

Make sure that all packing material is removed from the grill including tie-down straps.

Make a soap solution of one part liquid detergent and one part water. You will need a

spray bottle, brush, or rag to apply the solution to the fittings. For the initial leak test, make

sure the LP cylinder is full.

WARNING

NEVER PERFORM LEAK TEST WITH AN OPEN FLAME OR WHILE

SMOKING.

If there is excessive abrasion, wear, or damage to the hose, parts must be

replaced prior to operation. The replacement hose must be specified by the

manufacturer.

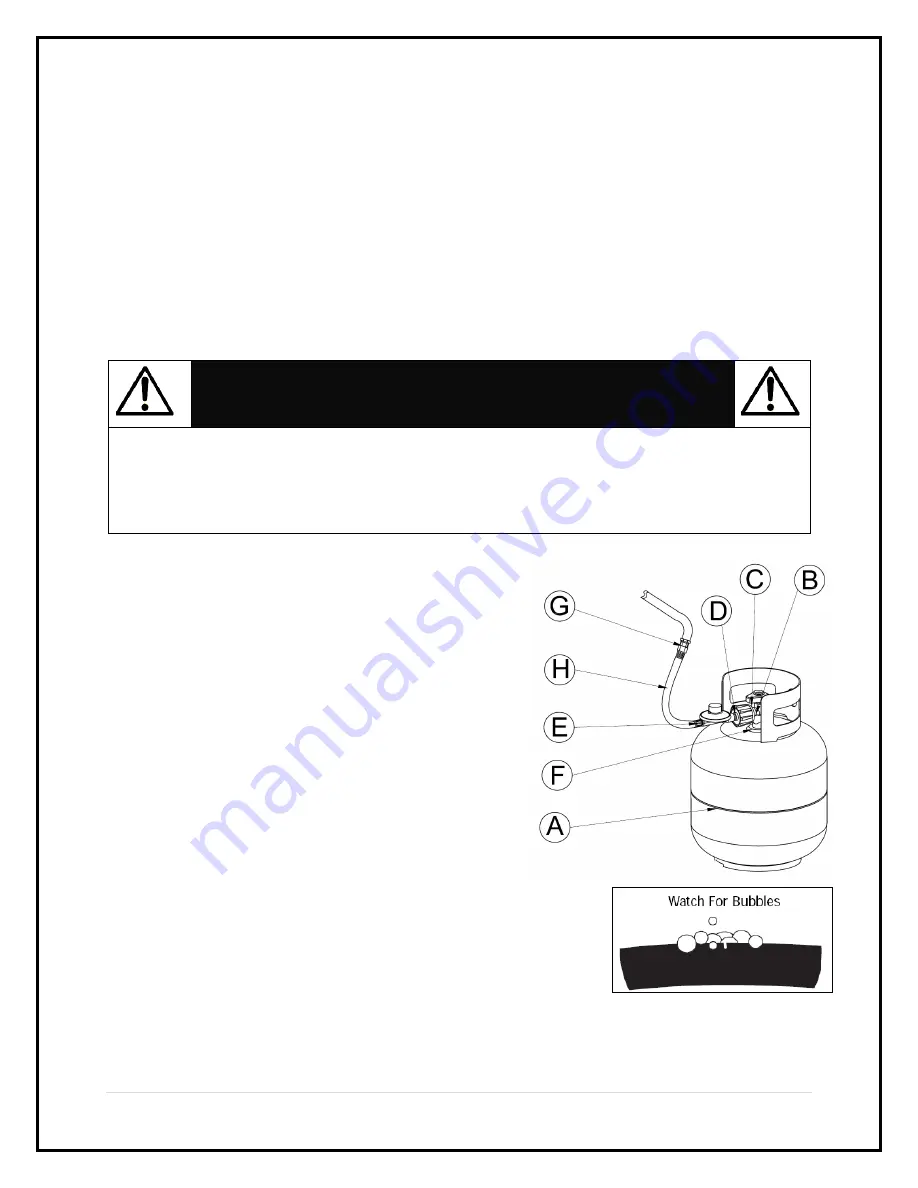

TO TEST

1. Make sure the control valves are in the

OFF

position then turn on the gas supply.

2. Check all connections from the gas cylinder, LP

gas regulator, and supply valve, including all

connections to the pipe for the burners.

Points where the soap-water mixture should be

applied

(soap bubbles will appear if a leak is present):

A Supply tank (cylinder) weld.

B Connection nut to tank valve.

C Back side of connection nut to brass nipple.

D Brass nipple connections to gas supply hoses.

E Regulator connections to gas supply hose.

F Tank valve to cylinder

G Hose connection to gas manifold.

H The full length of gas supply hose.

3. If a leak is present, immediately turn off the gas supply and tighten the leaky fittings.

4. Turn the gas back on and recheck.

Summary of Contents for Member's Mark GR2298906-MM-01

Page 7: ...7 P a g e Package Contents...