2. PRODUCT CHARACTERISTICS

>

rated voltage:

230V~ / 50Hz

>

refrigerant:

HFC-452A

; ODP = 0, GWP = 2140

>

operating temperature:

+2°C

÷

+10°C

>

sound pressure level:

<70dB (A)

Device / module*

width

[mm]

Device

depth

[mm]

Usable depth of

the device

[mm]

Usable width / depth

of shelves

[mm]

Usable exposition

area

[m

2

]

LED power

[W]

1330 / 1250

700

435

1220 / 342

2,23

20

1960 / 1880

930 / 342

3,36

25

* - refers to module dimensions (without glass sides – sides additionally 75mm)

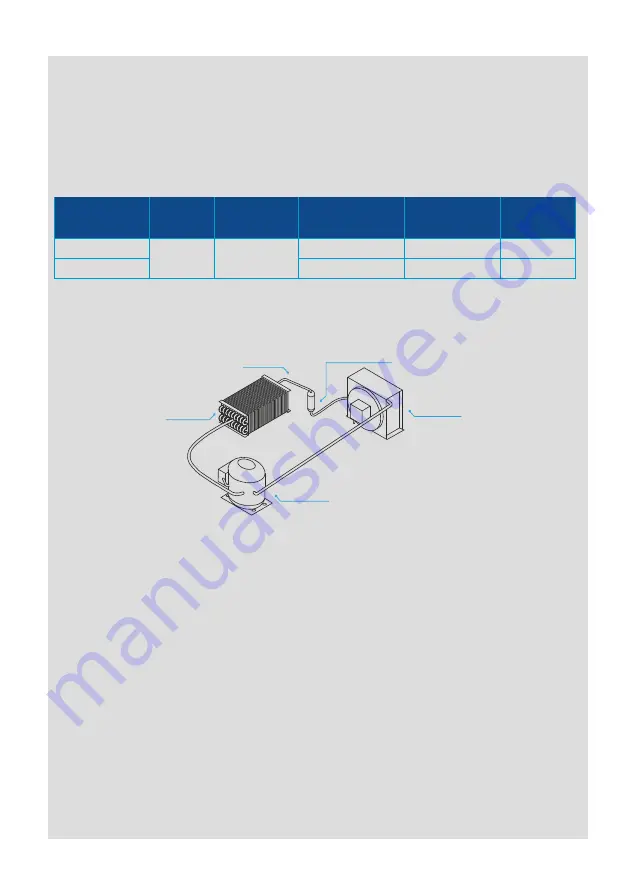

3. COOLING SYSTEM DIAGRAM

4. WIRING SYSTEM

1. The device is equipped with the protective PE cable.

2. Before connecting the device to the power supply, check the compatibility of the mains

voltage with the device supplying voltage (data on the plate).

3. Connecting the device to the mains socket should be made so that the plug of the

connecting cable is visible and easily accessible for the service.

4. The device should be connected to a separate, properly made electrical circuit protected

by a fuse no greater than 16 A with a B-characteristic, ended with a socket with a

protective pin (for model RCh-SR / 125, 133 – not stronger than 10A)

5. The device may be started only after confirming the effectiveness of the shock protection

with the results of measurements carried out in accordance with the applicable

regulations.

6. Before carrying out any maintenance or cleaning, turn off the device with the switch and

then remove the plug from the mains socket.

7. The device is started after connecting the plug to the mains socket, and then by turning

on the switch. The backlight of the switch indicates that the device has been turned on.

8. Any repair of electrical installation and replacement of the connection cable (only into

original one available from the manufacturer) may be carried out by an authorized

electrician only.

evaporator

capillary

chemical filter-dryer

condenser

compressor