17

Manual defrost

In order to activate the manual defrost press the

“DOWN”

switch for more than

3 sec. The essential condition is the temperature has to be lower than +6°C.

Temperature checking on the defrost probe

press the

“SET” switch for longer than 3 sec. (in case there is the alarm is

activated it is necessary to switch the sound alarm off first). On the display there

will appear “PS” symbol (password);

go to the “d/” parameter be means of the “UP” and/or “DOWN” switches, then

press the “SET” switch - there will appear temperature of defrost probe and the

symbol or

hold the “SET” switch for longer than 3 sec. (after 60 sec. automatic return) –

return to the temperature probe indication.

Access for operator to parameters configuration and its modification

press the „SET” switch for longer than 3 sec. (in case there is alarm activated,

switch the sound alarm first). On the display will appear the

„PS” symbol (service

parameter password protected);

go to the next parameters by means of the “UP” and/or “DOWN” switches;

press the “SET” switch to view the current value of parameter setting;

increase or decrease setting value by means of the “UP” and “DOWN” switches;

press the “SET” switch to temporarily save the entered new value – it will cause

as well return to the parameters list;

repeat the above operations

– if it is necessary;

press and hold the “SET” switch for longer than 3 sec. – it will cause parameters

saving and exit from the programming procedure.

Warning:

If no button is pressed for 60 sec., all the changes made to the parameters,

temporarily saved in the RAM, will be cancelled and the previous settings restored.

If power is disconnected from the instrument before saving the settings (pressing

the “SET” switch for 3 sec.), all the changes made to the parameters and

temporarily saved will be lost.

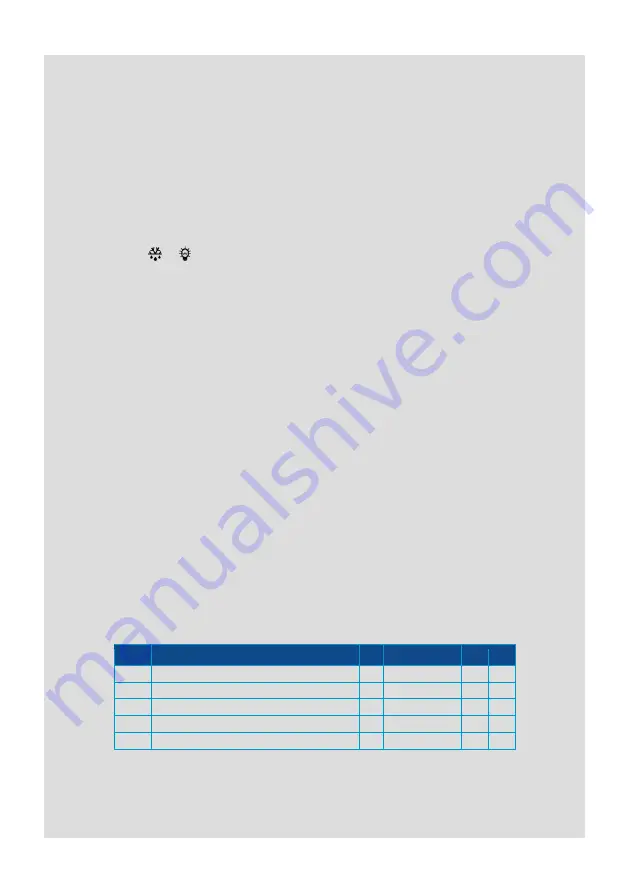

Symbol

Parameter

Unit

Fabric setting

min.

max.

d8

Alarm bypass time after defrost

h

2

0

15

A0

Alarm and fan temperature differential

°C

2

0

20

AL

Absolute or relative temperature for low temperature alarm

°C

2

0

150

AH

Absolute or relative temperature for high temperature alarm

°C

8

0

150

Ad

Temperature alarm delay

min

60

0

199

High temperature alarm activation = s AH

High temperature alarm deactivation = s AH

– A0

Low temperature alarm activation = setting

– AL

Low temperature alarm deactivation = setting

– AL + A0