Visit us at

www.rapala.ca

6

Operator's Manual

RAPALA

®

Power Ice Auger

(SERVICE, continued from page 5)

When servicing or repairing the engine, do not tip the engine

over or up unless specifically instructed to do so in this manual.

Service and repair procedures can be done with the engine

in an upright position. Some procedures will be easier if the

engine is lifted on a raised platform or working surface.

• To reduce fire hazard, keep engine free of debris build-up.

Clean up oil or fuel spillage. Allow engine to cool before

storing.

• Stop and inspect the equipment if you strike an object.

Repair, if necessary, before restarting.

• Clean and replace safety and instruction decals as necessary.

• To guard against engine over-heating, always have engine

debris filter mounted and clean.

• Inspect engine before storage. When not in use, disconnect

spark plug lead and store indoors in a dry place locked or

otherwise inaccessible to children.

• Use only original equipment parts from Rapala, including all

nuts and bolts.

StEPS fOR WORkING ON ENGINE OR AUGER

1. Turn off engine switch.

2. Disconnect the spark plug wire from the spark plug.

3. Securely place the disconnected spark plug wire away from

the spark plug and any metal parts. This must always be done

or arcing may occur between spark plug wire and metal parts.

4. Replace or repair the part on the engine or auger.

5. Check all parts that were repaired, or removed during repair,

that they are secure and fit correctly.

NOTE: All repair parts must come from the factory. Never

replace parts that are not specifically designed for the

engine or auger.

6. Reconnect spark plug wire to the spark plug.

PRE-OPERAtION

PREPARING ENGINE fOR StARtING

Before starting your unit, make sure the black throttle cable

housing is seated all the way into the brass ferrule at the engine

side of the cable.

GAS AND OIL

Quality

To operate the engine, we recommend using Viper® brand 2-cycle

oil (p/N 300400) to ensure that the engine operates correctly

throughout the life of the engine. Viper® brand 2-cycle oil has

fuel stabilizer additive which helps to prevent gasoline from

oxidizing and gumming up the carburetor when the unit is not

in use for long periods of time. Use unleaded regular gas only.

It is best to use premium gasoline that has no ethanol content.

Mixture

Run ice auger with a 50:1 ratio.

MIxING fUEL AND fILLING fUEL tANk

Mixing fuel

1. Fuel must be mixed in a container outside in a well ventilated

area.

2. Fill certified fuel container 1/4 full of recommended fuel.

3. Add recommended amount of 2 cycle oil with fuel stabilizer.

4. Screw container cap on straight and tight.

5. Shake the container to mix fuel and oil.

6. Wipe away any spilled fuel or oil and allow to evaporate before

moving or transporting.

filling fuel tank

1. Shut-off engine and allow engine to completely cool before

refilling the fuel tank.

2. Move to a well ventilated area, outdoors, away from flames

and sparks.

3. Clean debris from area around the fuel cap.

4. Loosen fuel cap slowly. place the cap on a clean, dry surface.

5. Carefully add fuel without spilling.

6. Do not fill fuel tank completely full, allow space for fuel to

expand.

7. Immediately replace fuel cap and tighten. Wipe off spilled

fuel and allow to dry before starting engine.

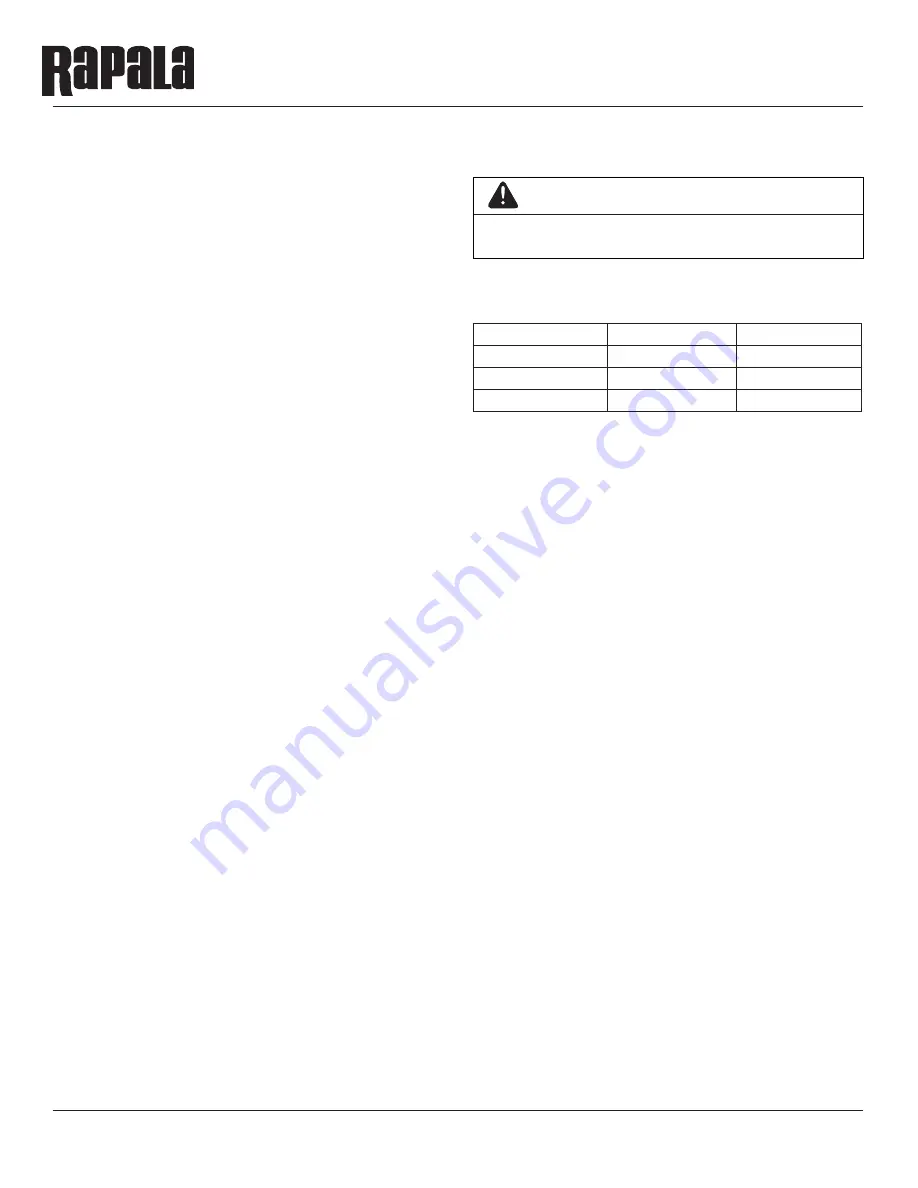

GAS

OIL

RAtIO

1 gallon

2.5 ounces

50:1

2 gallons

5 ounces

50:1

5 gallons

13 ounces

50:1

IMPORtANt

tHIS ENGINE USES A GAS/OIL MIxtURE. DO NOt RUN ON

StRAIGHt GAS ONLy, ENGINE DAMAGE WILL RESULt.