SECTION 7: V

ENTING

11 of 59

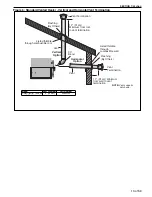

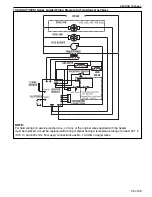

concentric vent box and a concentric vent/air intake

pipe penetrates the wall or roof. See Page 15,

Figure 9 and Page 16, Figure 10.

For separated combustion installation, the vent and

air intake must be fitted with an individual and

correctly sized sealed system and the vent and air

intake must terminate at approved wall and roof

terminals.

Separated combustion units may not be common

vented.

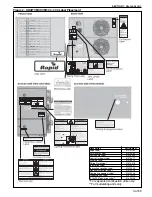

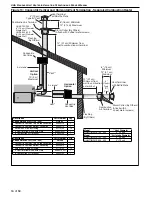

7.3 Horizontal Venting

Horizontally vented heaters must be individually

vented, no common venting.

Vent pipe must be sloped ¼" (.6 cm) for every 1' (.3

m).

In noncombustible walls only, vent terminal

(P/N 02537801-1P) may be used.

For 4'' (10 cm) vents in either combustible or

noncombustible walls, use vent terminal (P/N

90502100) or equivalent insulated vent terminal.

Follow the manufacturer's instructions for proper

installation.

Instead of an insulated vent terminal, a listed thimble

with 2" (5 cm) air gap, may be used with a 4" (10 cm)

vent cap (P/N 90502102).

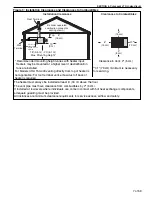

7.4 Vertical Venting

Vertically vented standard vented heaters can be

common vented (up to 4 heaters).

Vent pipe must be sloped 1/4'' (.6 cm) for every

1' (.3 m).

For 4'' (10 cm) common vent, an approved vent cap

(P/N 90502102) must be used.

For 6'' (15 cm) common vent, an approved vent cap

(P/N 90502103) must be used.

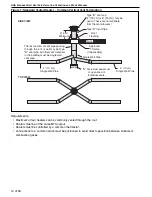

For common vertical venting of more than two

heaters, See Page 14, Figure 7.

A vent shall not extend less than 2' (.6m) above the

highest point where it passes through a flat roof of a

building.

7.5 Maximum Vent Lengths Table

7.6 Vent Material

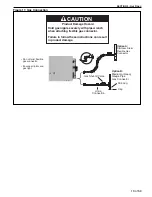

Vent material may be single wall 26 ga. (minimum)

galvanized steel or equal thickness stainless steel.

Completely seal all joints, refer to Page 10, Section

7.2.

If penetrating a combustible wall or roof, a listed

thimble with 2" (5 cm) clearance must be used.

Where local codes permit, a single section of type

B-1 vent material may be used at the roof or wall

penetration instead of a thimble. Ensure vent

manufacturer's clearance from vent material is

maintained. Seal annular space of the type B-1 vent

as well as all joints in the remaining vent.

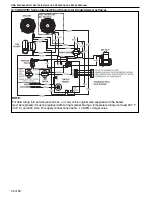

7.7 Replacing an Existing Heater in a Venting

System

When replacing an existing heater in a venting

system, the venting system may not be properly

sized to vent the new heater. The following steps

must be followed with each piece of equipment

connected to the venting system placed in

operation, while any other equipment connected to

the venting system are not in operation.

1. Seal any unused openings in the venting

system.

2. Inspect the venting system for proper size and

horizontal pitch, as required by the NFPA 54/

ANSI Z223.1 - latest revision, National Fuel

Gas Code (US) or Standard CSA B149.1

Natural Gas and Propane Installation Code

(Canada) and these instructions. Determine

that there is no blockage or restriction, leakage,

corrosion and other deficiencies which could

cause an unsafe condition.

3. Close all building doors and windows and all

doors between the space in which the piece(s)

of equipment connected to the venting system

are located and other spaces of the building.

Turn on clothes dryers and any exhaust fans,

such as range hoods and bathroom exhausts

so that they shall operate at maximum speed.

Do not operate a summer exhaust fan. Close

fireplace dampers.

4. Follow the lighting instructions. Place the

equipment being inspected in operation. Adjust

thermostat so that the equipment will operate

continuously.

5. For any equipment having a draft hood, test for

draft hood equipment spillage at the draft hood

relief opening after five minutes of main burner

operation. Use the flame of a match or candle.

6. After it has been determined that each piece(s)

of equipment connected to the venting system

properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

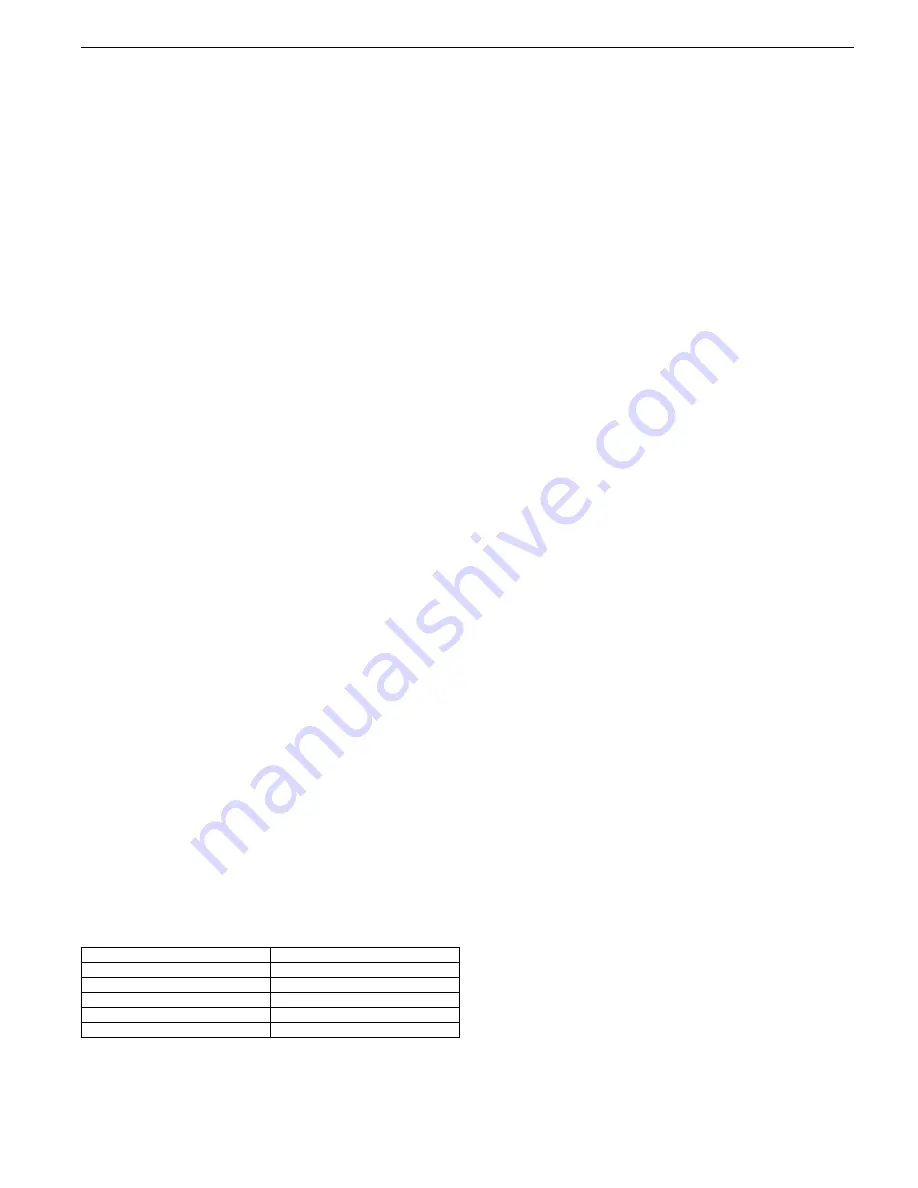

Model UHA[T][M][X][S]150-400

# of Elbows

30 ft (9.1 m)

1

25 ft (7.6 m)

2

20 ft (6.1 m)

3

15 ft (4.5 m)

4

10 ft (3.0 m)

5

Summary of Contents for UHAM 150

Page 2: ......

Page 4: ......

Page 8: ......

Page 50: ...UHA STANDARD UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL 42 of 59 14 1 General ...

Page 65: ...SECTION 16 SPECIFICATIONS 57 of 59 16 4 Dimension Data for Models UHA T M X S 300 400 ...

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......