UHA S

TANDARD

U

NIT

H

EATER

I

NSTALLATION

O

PERATION AND

S

ERVICE

M

ANUAL

18 of 59

SECTION 9: GAS PIPING

A gas meter is connected to the service pipe by the

gas supply company. An existing meter should be

checked, preferably by the company, to ensure that

the meter is adequate for the rate of gas supply

required.

Installation pipes must be fitted in accordance with

local and national codes. Pipes of smaller size than

the heater inlet gas connection should not be used.

Gas lines must meet applicable codes:

United States:

Flexible stainless steel gas hose

(US models) is certified per the standard for

connectors for gas equipment, ANSI Z21.21/CSA

6.10 - latest revision.

Canada:

Rubber type 1 gas hose (Canadian

models) is certified as being in compliance with the

standard for elastomeric composite hose and hose

couplings for conducting propane and natural gas,

CAN/CGA 8.1 - latest revision.

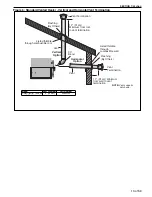

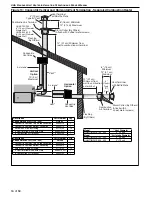

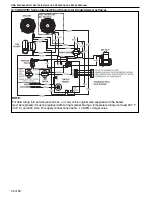

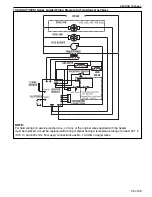

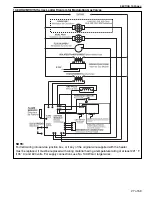

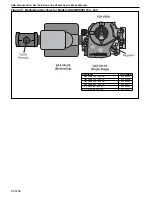

9.1 Connections

Connect the heater to the gas supply ensuring that

the final connections are as follows:

• Gas supply pipe work is run in medium or heavy

gauge tubing in compliance with local and

national codes.

• Meter and service must be large enough to

handle all the burners being installed plus any

other connected load. The gas pipe which feeds

the system must be large enough to supply the

required gas with a maximum pressure drop of

1/2 in wc. When gas piping is not included in the

layout drawing, contact the local gas supplier.

• An isolating valve and union connection should

be used and fitted into the supply adjacent to the

heater.

• A minimum 1/8" NPT plugged tapping

accessible for test connection must be installed

immediately upstream of the gas supply

connection to the heater.

• For suspended heaters, an approved metal

flexible connection between the isolating valve

and the heater may be used.

To reduce

pressure loss, use one pipe size larger than

the heater gas connection.

IMPORTANT

- The complete installation must be

purged and tested for gas soundness in accordance

with local and national codes.

Caution:

Do not high pressure (in excess of 1/2 psi

[14 in wc]) test the gas piping with the burner

connected. Close manual shut-off valve during any

pressure testing equal to less than 1/2 psi (14 in wc).

Check the pipe and tubing ends for leaks before

placing heating equipment into service. When

checking for gas leaks, use a soap and water

solution; never use an open flame.

WARNING

Fire Hazard

Connect gas supply according to Figure 11.

Do not use gas supply pipe and electrical

connections to support the heater’s weight.

Gas can leak if not installed properly.

Failure to follow these instructions can result

in death, injury or property damage.

WARNING

Explosion Hazard

Leak test all components of gas piping

before operation.

Gas can leak if piping is not installed

properly.

Do not high pressure test gas piping with

heater connected.

Failure to follow these instructions can result

in death, injury or property damage.

Summary of Contents for UHAM 150

Page 2: ......

Page 4: ......

Page 8: ......

Page 50: ...UHA STANDARD UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL 42 of 59 14 1 General ...

Page 65: ...SECTION 16 SPECIFICATIONS 57 of 59 16 4 Dimension Data for Models UHA T M X S 300 400 ...

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......