SECTION 3: C

RITICAL

C

ONSIDERATIONS

5 of 59

SECTION 3: CRITICAL CONSIDERATIONS

3.1 Basic Information

UHA[T][M][X][S] heaters have automatic ignition

burners for ON/OFF, HIGH/LOW or modulate within

the range of HIGH/LOW operation.

3.2 Manufactured Units

Gas-fired, power-vented unit heater with tubular heat

exchanger. Units shall have a minimum of 82%

thermal efficiency. The standard unit shall consist of

a non-separated combustion design with an

aluminized heat exchanger and single stage gas

valve. Design and heat exchanger alternatives shall

be offered as follows:

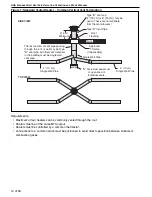

• Separated Combustion: [S] A separated

combustion unit shall consist of a sealed

enclosure with a hinged door. Combustion air

inlet on rear of heater allows for intake venting

from outside of heated space to be attached.

Combustion flue gases shall be ducted from

outside heated space by ductwork connected to

unit’s outlet flange.

• Stainless Steel Heat Exchanger: [X] A stainless

steel heat exchanger unit shall consist of heat

exchanger tubes, heat exchanger tube supports

and heat exchanger tube plate produced of 409

stainless steel. Air inlet temperatures below 40

°F (4.5 °C) are not recommended for this

application.

• Two Stage Gas Valve: [T] A two-stage gas valve

shall allow heater to function in either high or low

fire.

• Modulating Gas Valve: [M] A modulating gas

valve shall allow heater to modulate between

high and low fire.

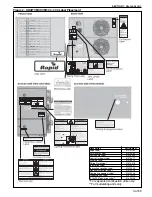

3.3 Location and Suspension

All models:

• Must be installed indoors.

• Must be installed in a level position with

horizontal discharge.

• May be mounted on a shelf of non-combustible

material.

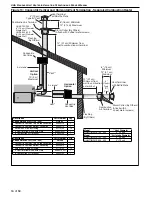

• May be suspended from above (See Page 9,

Figure ) or from wall brackets of sufficient

strength to support the heater as listed in the

Technical Data Table on Page 56, Section 16.2

• Drop rods must be a minimum of 3/8" diameter

mild steel. Four suspension points (3/8" nuts)

are located on top of the heater.

• Must be installed in a manner which allows

access to all serviceable components.

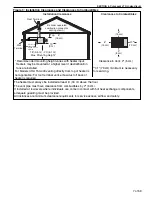

3.4 Minimum Required Installation Clearances

Clearances around the heater and vent must be as

indicated on Page 7, Figure 3 and Page 10, Section

7 to ensure access for servicing and correct

operation.

3.5 Ventilation

It is important to ensure that there is adequate air

space around the heater to supply air for

combustion, ventilation and distribution in

accordance with local and national codes on Page

10, Section 7.

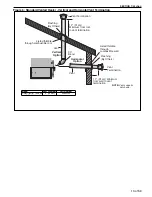

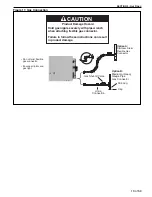

3.6 Gas Supply

It is important that the gas supply pipe is sized

correctly to provide the inlet pressure as stated on

the heater serial plate. The gas supply pipe and

electrical connections must not support any of the

heater's weight. See Page 18, Section 9.

3.7 Electrical Supply

A permanent 120 V / 1 Ø / 60 Hz electrical supply is

required for the main electrical power. The heater

also requires suitable controls in accordance with

Page 20, Section 10.

3.8 Vent

Choose heater orientation to allow for the proper

location of the vent. Each heater must be fitted with

a correctly sized sealed vent system.

If vented horizontally, no other equipment may be

connected to the vent. See Page 10, Section 7.

Summary of Contents for UHAM 150

Page 2: ......

Page 4: ......

Page 8: ......

Page 50: ...UHA STANDARD UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL 42 of 59 14 1 General ...

Page 65: ...SECTION 16 SPECIFICATIONS 57 of 59 16 4 Dimension Data for Models UHA T M X S 300 400 ...

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......