UHA S

TANDARD

U

NIT

H

EATER

I

NSTALLATION

O

PERATION AND

S

ERVICE

M

ANUAL

38 of 59

and electrical supply. Remove the fan(s) and use a

small brush or duster to clean the fan blades from

each side. Replace fan when done. See Page 53,

Section 15.10.

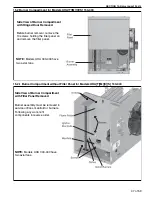

13.4 Heat Exchanger Maintenance

The heat exchanger will remain clean unless a

problem has developed with combustion. Inspect the

heat exchanger. Look for signs of overheating at the

front tubes which may indicate burner over firing or

persistently low air flows.

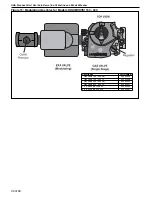

13.5 Gas Valve Maintenance

No regular maintenance is required on this device.

To change gas control valves, See Page 46, Section

Do not repair or disassemble gas valve.

Replace faulty gas valves with genuine replacement

parts sold and supplied by Rapid Engineering LLC.

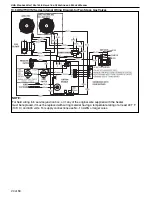

13.6 Flue Blower

The flue blower should not require maintenance.

However, if the air pressure switch is causing burner

lockout, then remove the flue blower from the vent

box by unscrewing the screws at the mounting plate.

Screw quantity will vary by model size. Remove the

screws attaching the mounting plate to the fan inlet

See Page 51, Section 15.6 through Page 52,

Section 15.7. Ensure that the fan is free to run and

that the fan wheel is clean.

13.7 Venting and Air Intake Pipe

Inspect all venting and air intake pipe. Ensure that

all seams are sealed and suspension points secure.

Repair suspension points if any part of the venting

or combustion air pipe is sagging. Check to make

sure any insulation is not missing or in poor

condition. Replace as necessary. Check all venting

and air intake components to ensure they are in

good condition, gas tight and corrosion-free.

13.8 Maintenance Checklist

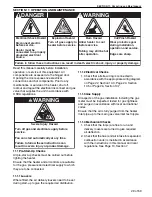

Installation Code and Annual Inspections:

All

installations and service of RAPID

®

equipment must

be performed by a contractor qualified in the

installation and service equipment sold and supplied

by Rapid Engineering LLC and conform to all

requirements set forth in the RAPID

®

manuals and

all applicable governmental authorities pertaining to

the installation, service, operation and labeling of

the equipment.

To help facilitate optimum performance and safety,

Rapid Engineering LLC recommends that a qualified

contractor conduct, at a minimum, annual

inspections of your RAPID

®

equipment and perform

service where necessary, using only replacement

parts sold and supplied by Rapid Engineering LLC.

Annual Fall Start-Up

Follow entire start-up procedure at this time and check control settings and

operation.

The Vicinity of the Heater

Do not store or use flammable objects, liquids or vapors near the heater.

Immediately remove these items if they are present.

Vehicles and Other

Objects

Maintain the clearances to combustibles.

Do not hang anything from, or place anything on, the heater.

Make sure nothing is lodged in between the heat exchanger or in the louvers.

Immediately remove objects in violation of the clearances to combustibles.

Vent Pipe/Terminals

Venting must be intact. Using a flashlight, look for obstructions, cracks on the

pipe, gaps in the sealed areas or corrosion.

The area must be free of dirt and dust.

Remove any carbon deposits or scale using a wire brush.

If the vent terminal has a screen built in, remove any dirt, dust or deposits

from the screen.

Summary of Contents for UHAT 150

Page 2: ......

Page 4: ......

Page 8: ......

Page 50: ...UHA STANDARD UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL 42 of 59 14 1 General...

Page 65: ...SECTION 16 SPECIFICATIONS 57 of 59 16 4 Dimension Data for Models UHA T M X S 300 400...

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......