Rapid Spray FieldLink Operators Handbook

Rapid Spray Equipment by Rapid Spray

REV OCT 2019

13

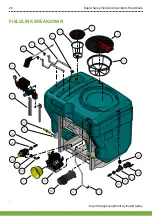

FITTING PTO SHAFT

STEP-BY-STEP PTO SHAFT CUTTING GUIDE

1.

Install the PTO shaft onto the tractor and FieldLink while shaft is horizontal and at it's

shortest length. If you cannot fit the shaft at this point as it is too long, it will need to

be shortened further.

2.

Without running the PTO, lower the FieldLink to the ground and check the angle of

the shaft and universal joints. This angle should not exceed 25° at rest.

3.

Raise the FieldLink to the maximum operating height and check the angle of the shaft

and universal joints. This angle should not exceed 17° for continuous operations.

4.

Lastly, check the overlap of the shaft end exceeds 50% of the total length of the shaft

operation to prevent premature failure of the shaft.

See

https://resources.rapidspray.net/blog/how-to-

correctly-size-your-3pl-shaft

for full guide with images.