SECTION 22: T

ROUBLESHOOTING

143 of 147

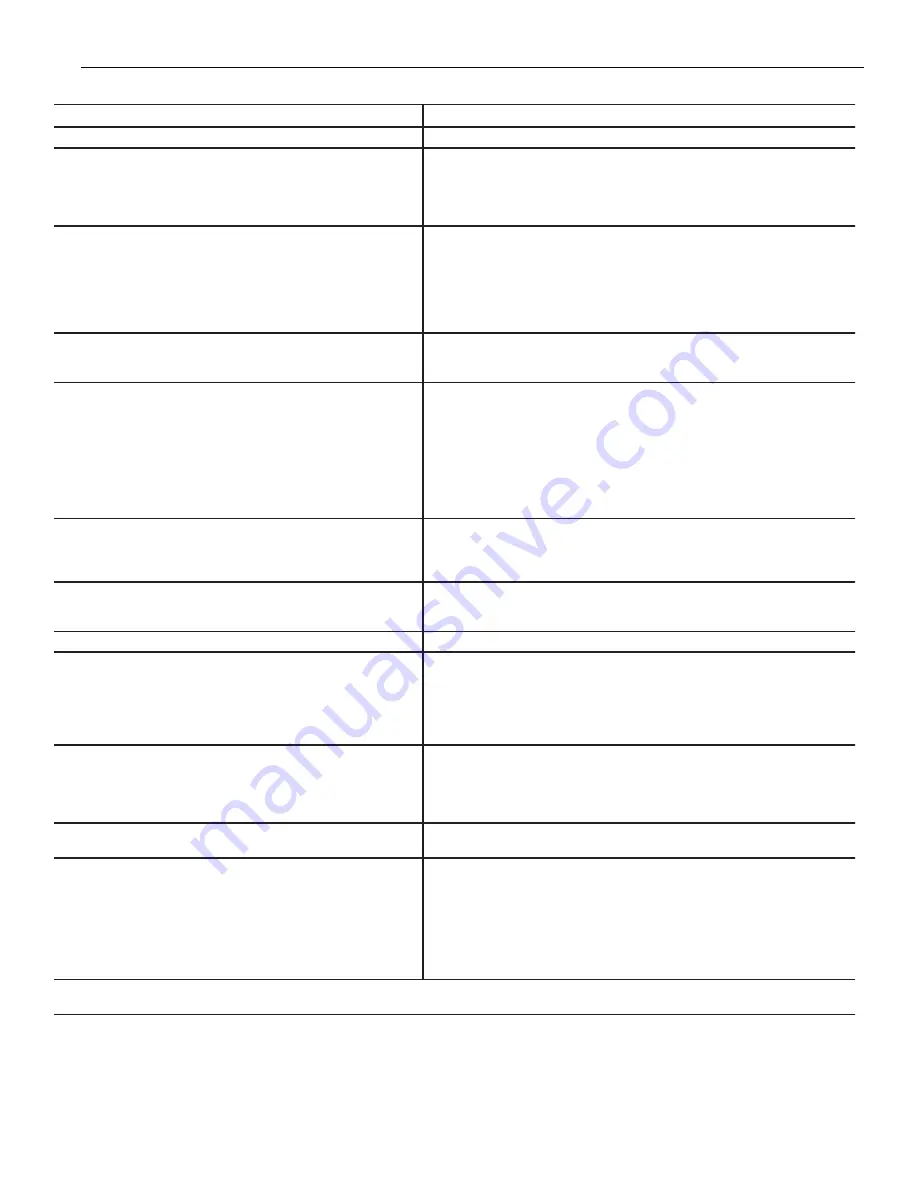

FIELD TEST

REMEDY

1. Arrow on side of valve should point in direction of gas fl ow.

1. Install properly.

2. Remove wires connected to amplifi er terminals 6 & 7 and mea-

sure resistance. MR212 (60-80 ohms), M611 (45-55 ohms).

3. Inspect - plunger should be installed per Maxitrol product infor-

mation sheet and operate freely in solenoid sleeve.

4. Disassemble valve for inspection of internal parts.

2. If proper resistance values are not observed, replace modulator head or

repair wiring.

3. Clean or replace plunger if necessary and install per Maxitrol product infor-

mation sheet.

4. Replace diaphragm if ruptured.

5. Check for 24VAC at amplifi er terminals 8 & 9.

6. Measure resistance per item 2.

7. Remove wires connected to amplifi er terminals 1, 2, & 3. Mea-

sure resistance across wires 1 & 3, then 2 & 3. Meter should read

greater than 2500 ohms.

8. Follow procedures outlined in “PRELIMINARY CIRCUIT ANALY-

SIS” (Sections I & II) in Maxitrol product information sheet.

5. Provide 24VAC to amplifi er. Refer to item 24.

6. If proper resistance values are not observed, replace modulator head or

repair wiring.

7. If readings are incorrect, replace the TS144 or repair wiring.

8. If power source and modulator coil check out (items 5 & 6) but proper modu-

lating voltages cannot be obtained, then amplifi er may be assumed at fault.

Install replacement amplifi er.

9. See Valve Adjustments - Section 19.5.

10. Measure manifold pressure as outlined in Section 19.4.

9. Adjust to proper low fi re.

10. If greater than 1.0 in wc negative pressure, check equipment for clogged

fi lters & other inlet air restrictions. For other solutions, consult factory.

11. Follow procedures outlined in “PRELIMINARY CIRCUIT ANALY-

SIS” (sections I & II), in Maxitrol product information sheet.

12. Remove wires connected to amplifi er terminals 4 & 5. Set T244

or TD244 to maximum setting. Measure resistance across wires.

Meter should read 6000 ohms +/- 1000 (T244). If TS244/TD244 are

used, meter should read 4500 ohms +/- 1000 (TS244) and 2100

ohms +/- 150 (TD244).

13. Follow procedures outlined in “PRELIMINARY CIRCUIT ANALY-

SIS” (Sections IV), in Maxitrol product information sheet.

11. If amplifi er is proven at fault, install replacement amplifi er.

12. If reading is incorrect, replace the T244, TS244/TD244 or repair wiring.

13. If proper action is obtained, fi rst check item 12. Recalibrate if necessary

See section 19.7.

14. Compare sensed temperature reading at TS144 with average

discharge air temperature.

15. Follow procedures outlined in “PRELIMINARY CIRCUIT ANALY-

SIS” (Sections IV), in Maxitrol product information sheet.

14. Move TS144 to location where average temperature can be sensed.

15. If proper temperatures are not observed, refer to temperature calibration

procedures, in Maxitrol product information sheet.

16. Remove button Plate and inspect valve and seat

17. Inspect - plunger should be smooth and clean and operate

freely in solenoid sleeve.

16. Clean, replace valve and/or seat if necessary.

17. Clean, or if necessary, replace plunger.

18. Measure resistance per item 7.

18. If readings are incorrect, replace the TS144 or repair wiring.

19. Read inlet pressure at valve, using a manometer with heater

operating at full fi re. Pressure should be at least equal to the sum

of: outlet pressure setting and pressure drop of the valve (See Max-

itrol Capacity Chart Bulletin) plus 1.0 in wc.

20. Read outlet pressure using manometer and compare with

recommendation of equipment manufacturer.

19. Increase inlet pressure if possible or change to larger valve. Consult factory

about possibility of using special spring to reduce pressure drop on selected

installations.

20. See valve adjustments in section 19.5.

21. Follow procedure outlined in “PRELIMINARY CIRCUIT ANALY-

SIS” (Sections I & II), in Maxitrol product information sheet.

22. Measure resistance per item 12.

23. Follow procedures outlined in “PRELIMINARY CIRCUIT

ANALYSIS: (Section IV), in Maxitrol product information sheet.

21. If amplifi er is proven at fault, install replacement amplifi er.

22. If reading is incorrect, replace the T244, TS244/TD244 or repair wiring.

23. If proper action is obtained, fi rst check item 22. Recalibrate if necessary.

Refer to Temperature Calibration Proceedures in Maxitrol product information

sheet

24. Measure resistance per item 2.

24. If proper resistances are not observed, replace modulator head or repair

wiring.

25. Check to see if heater is delivering air at maximum discharge

air setting.

26. Check to see if heater is delivering air at maximum discharge

air setting.

27. Check to see if heater is operating at high fi re.

28. Place thermometer next to T244 or TS244. Compare space

temperature reading with T244 or TD244 dial setting.

25. If desired temperature is not reached, increase maximum discharge air

temperature setting.

26. If desired space temperature is not reached, decrease minimum discharge

air temperature setting.

27. If desired space temperature is not reached with heater at high fi re, it may

be undersized. Consult manufacturer.

28. If temperature reading is incorrect, check items 25, 26, & 27, then recalibrate

if necessary.

Summary of Contents for 2005

Page 2: ......

Page 4: ......

Page 8: ......

Page 10: ......

Page 31: ...SECTION 7 ROOF CURB 21 of 147 FIGURE 12 Curb Mounting Air Handler Roof Curb Fastening Detail...

Page 154: ...B SERIES INSTALLATION OPERATION AND SERVICE MANUAL 144 of 147...

Page 158: ......

Page 160: ......

Page 161: ......

Page 162: ......