SECTION 24: T

ROUBLESHOOTING

137 of 154

24.1 Initial Checks

When enco

u

ntering any abnormal operation or fa

u

lt conditions of the eq

u

ipment, all tro

u

bleshooting sho

u

ld

start

w

ith the follo

w

ing initial checks. If a problem is disco

v

ered in these initial checks it m

u

st be corrected

before mo

v

ing on in the tro

u

ble shooting.

1. Compare

v

oltage and phase of s

u

pply po

w

er on site

w

ith rating plate information.

2.

Re

v

ie

w

w

iring bet

w

een remote panel and control panel. Do the electrical connections match the s

u

p-

plied

w

iring diagram?

3.

Compare gas type and s

u

pply press

u

re on site

w

ith rating plate information.

4.

Check for proper blo

w

er rotation on air handler and any exha

u

st blo

w

ers.

• Blo

w

ers po

w

ered

w

ith a three phase motor can be re

v

ersed by s

w

apping any t

w

o incoming po

w

er

legs. For blo

w

ers po

w

ered by a single phase motor refer to the motor rating plate for re

v

ersing

instr

u

ctions.

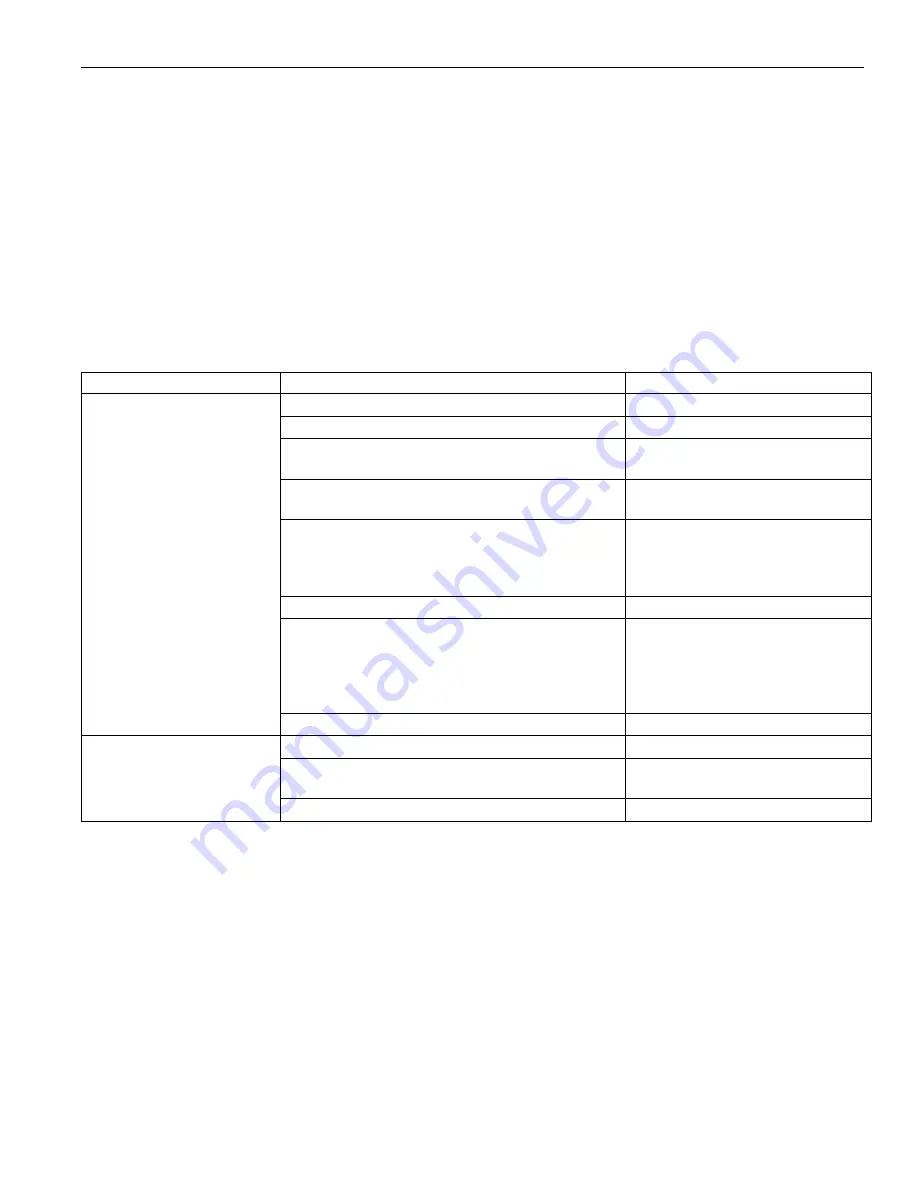

24.2 Motor and Blower

PROBLEM

POSSIBLE CAUSE

SOLUTION

Motor does not operate

Main disconnect s

w

itch is OFF

T

u

rn disconnect to ON

Blo

w

n f

u

se(s) in disconnect

Replace f

u

se(s)

Blo

w

n f

u

se(s)/breaker tripped in control transformer Replace f

u

se(s)/reset breaker (

w

ith

disconnect off)

Fan s

w

itch on

Check

w

iring bet

w

een remote panel

and air handler. Replace s

w

itch.

Optional: Damper does not open

Check that damper is not obstr

u

cted

Check that linkage is tight and

sec

u

re

Replace damper act

u

ator

Motor starter (contactor) does not operate.

Replace starter

Tripped motor o

v

erload. Po

w

er o

u

t to MUA motor

w

hen motor starter is energized?

Reset

Check for proper FLA setting

Replace o

v

erload

If applicable: Tighten scre

w

s on

heater packs or o

v

erload.

Optional: Lo

w

limit s

w

itch set to high

Re-adj

u

st lo

w

limit s

w

itch setting

Blo

w

er does not operate

Belts broken or loose?

Replace/tighten belts

Loose motor or blo

w

er shea

v

es (p

u

lleys)

Reinstall and properly torq

u

e set-

scre

w

s

Blo

w

er bearings, do they t

u

rn freely?

Replace bearing(s)

Summary of Contents for 4044

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 73: ...SECTION15 VIBRATION ISOLATION 65 of 154 FIGURE 52 Curb Mounted Roof Curb Roof Curb...

Page 109: ...SECTION19 ELECTRICAL 101 of 154...

Page 110: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 102 of 154...

Page 111: ...SECTION19 ELECTRICAL 103 of 154...

Page 112: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 104 of 154...

Page 113: ...SECTION19 ELECTRICAL 105 of 154...

Page 114: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 106 of 154...

Page 115: ...SECTION19 ELECTRICAL 107 of 154...

Page 116: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 108 of 154...

Page 117: ...SECTION19 ELECTRICAL 109 of 154...

Page 118: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 110 of 154...

Page 119: ...SECTION19 ELECTRICAL 111 of 154...

Page 121: ...SECTION 20 DIRECT FIRED BURNER 113 of 154 FIGURE 71 Midco HMA 2A Burner...

Page 122: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 114 of 154...

Page 125: ...SECTION 20 DIRECT FIRED BURNER 117 of 154...

Page 126: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 118 of 154...

Page 127: ...SECTION 20 DIRECT FIRED BURNER 119 of 154 20 3 Honeywell UV Flame Detector...

Page 160: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 152 of 154...

Page 161: ...SECTION 27 THE RAPID 4000 SERIES WARRANTY 153 of 154...

Page 162: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 154 of 154...