SECTION 7: A

IR

H

ANDLER

A

SSEMBLY

39 of 154

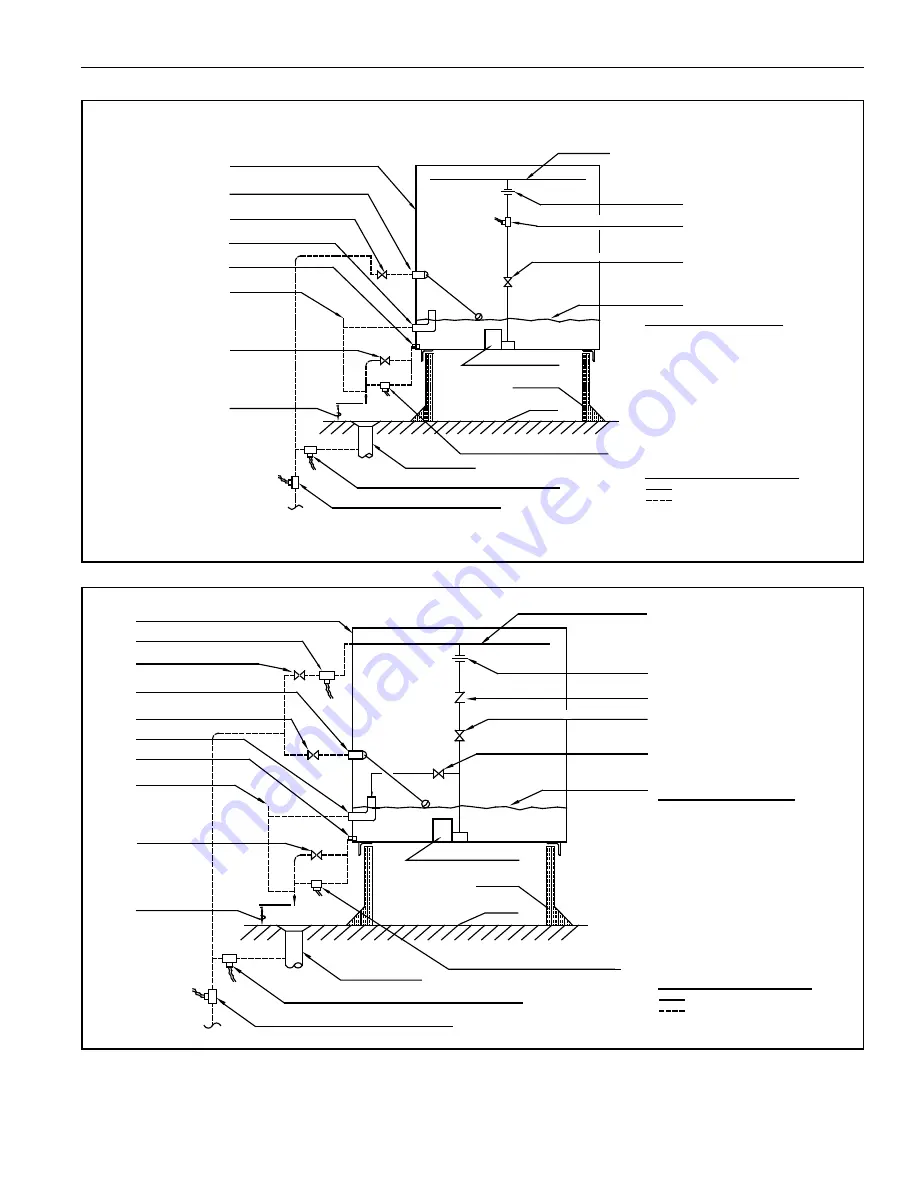

FIGURE 2

8

: Conductivity Control and Freeze Protection (Evaporative Coolin

g

Packa

g

e #2)

FIGURE 29: Protection and Auto-Flush (Evaporative Coolin

g

Packa

g

e #3)

HEADER

EVAPORATIVE COOLING MODULE

FLOAT VALVE & MAKE-UP CONN.

MANUAL SHUT-OFF VALVE

OVERFLOW CONN.

DRAIN CONN.

VACUUM BREAKER

MANUAL DRAIN VALVE

AIR GAP

PER CODE

UNION

WATER LEVEL

RECIRCULATION PUMP

ROOF CURB

ROOF DRAIN

SUPPLY LINE DRAIN SOLENOID 1” NORMALLY OPEN.

FILL VALVE SOLENOID 1” NORMALLY CLOSED.

SUMP DRAIN 1 1/2”

BALL VALVE POWERED OPEN & CLOSED

CONDUCTIVITY CONTROL

Factory furnished piping & devices.

Field furnished piping & devices.

Notes

Legend

1)

2)

3)

4)

All solenoids must be installed

in a line no smaller than the

solenoid orifice.

Pitch drain line minimum 1/8”

per foot towards outlet

Supply & supply line drain solenoids

must be installed in a non-freeze

location.

Makeup line must be installed

with no traps or sages above

the roof line.

WATER FLOW ADJUSTMENT VALVE

Factory furnished piping & devices.

Field furnished piping & devices.

Notes

HEADER

EVAPORATIVE COOLING MODULE

FLUSH SOLENOID NORMALLY CLOSED

MANUAL SHUTOFF VALVE

FLOAT VALVE & MAKE-UP CONN.

MANUAL SHUTOFF VALVE

OVERFLOW CONN.

DRAIN CONN.

VACUUM BREAKER

MANUAL DRAIN VALVE

AIR GAP

PER CODE

UNION

CHECK VALVE

BLEED-OFF VALVE

WATER LEVEL

RECIRCULATION PUMP

ROOF CURB

ROOF

ROOF DRAIN

SUPPLY LINE DRAIN SOLENOID 1” NORMALLY OPEN.

FILL VALVE SOLENOID 1” NORMALLY CLOSED.

SUMP DRAIN 1 1/2”

BALL VALVE POWERED OPEN & CLOSED.

Legend

1)

2)

3)

4)

All solenoids must be installed

in a line no smaller than the

solenoid orifice.

Pitch drain line minimum 1/8”

per foot towards outlet

Supply & supply line drain solenoids

must be installed in a non-freeze

location.

5) Header orifices serve as vacuum

break for flush solenoid connection

to header.

Makeup line must be installed

with no traps or sages above

the roof line.

WATER FLOW ADJUSTMENT VALVE

Summary of Contents for 4044

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 73: ...SECTION15 VIBRATION ISOLATION 65 of 154 FIGURE 52 Curb Mounted Roof Curb Roof Curb...

Page 109: ...SECTION19 ELECTRICAL 101 of 154...

Page 110: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 102 of 154...

Page 111: ...SECTION19 ELECTRICAL 103 of 154...

Page 112: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 104 of 154...

Page 113: ...SECTION19 ELECTRICAL 105 of 154...

Page 114: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 106 of 154...

Page 115: ...SECTION19 ELECTRICAL 107 of 154...

Page 116: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 108 of 154...

Page 117: ...SECTION19 ELECTRICAL 109 of 154...

Page 118: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 110 of 154...

Page 119: ...SECTION19 ELECTRICAL 111 of 154...

Page 121: ...SECTION 20 DIRECT FIRED BURNER 113 of 154 FIGURE 71 Midco HMA 2A Burner...

Page 122: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 114 of 154...

Page 125: ...SECTION 20 DIRECT FIRED BURNER 117 of 154...

Page 126: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 118 of 154...

Page 127: ...SECTION 20 DIRECT FIRED BURNER 119 of 154 20 3 Honeywell UV Flame Detector...

Page 160: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 152 of 154...

Page 161: ...SECTION 27 THE RAPID 4000 SERIES WARRANTY 153 of 154...

Page 162: ...4000 SERIES INSTALLATION OPERATION AND SERVICE MANUAL 154 of 154...