8.1 Bleed pipe system after changing barrel

8.1.1 Change barrel and reconnect any pipe.

8.1.2 Open second hole of barrel (A).

8.1.3 Disconnect delivery hose from automatic nozzle (B)

and insert deliveryhose into second hole of barrel (A).

8.1.4 Switch on pump (C) and run pump until suction and

delivery hose are filled.

8.1.5 Switch off pump (C) and reconnect delivery hose (B)

to automatic nozzle (B).

9. Disposal

In the event of maintenance or demolition of the machine, do not disperse contaminated parts into

the environment.

Refer to local regulations for their proper disposal.

10. Liability and Guarantee

10.1 In case of insufficient maintenance, faults on operation, use of not adequate spare parts

or attachments all liabilities and rights of claim under guarantee are void.

10.2 The manufacturer is not liable for improper use of the container or ignoring the safety

instructions.

10.3 Technical modifications are subject to change without announcement.

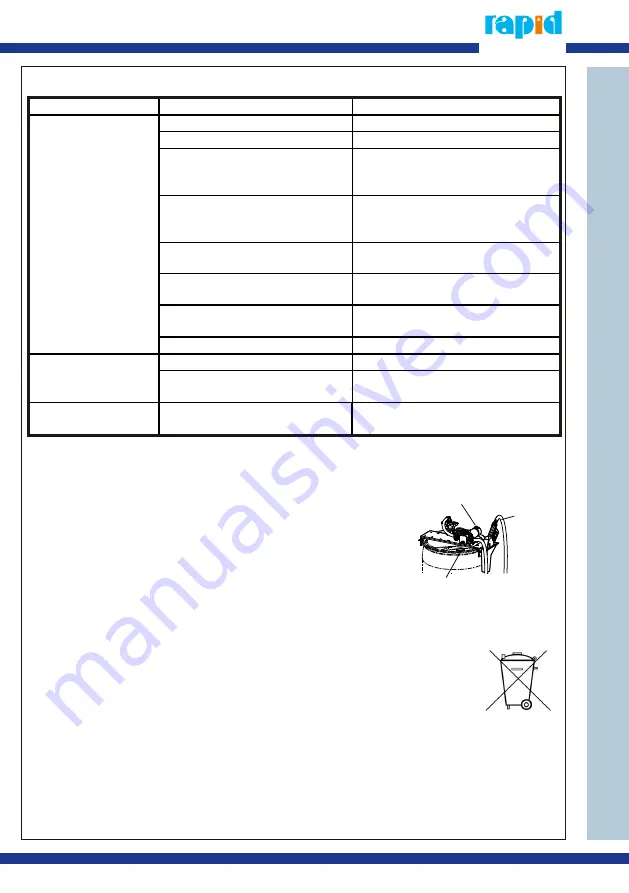

8. Maintenance and trouble shooting

Problem

Possible cause

Correct iv act ion

low or no ow rate

low level in the suction tank

rell the tank

filter clogged

clean the filter

excessive suction pressure

lower the pump with respect to the

level of the tank or increase the cross-

section of the tubing

high loss of head in the delivery

circuit (working with the by-pass

open)

use shorter tubing or of greater

diameter

air entering the pump or suction

tubing

check the seals of the connections

a narrow in the suction tubing

use tubing suitable for working under

suction pressure

the suction tubing is resting on the

bottom of the tank

raise the tubing

Nozzle clogged

Clean nozzle with warm water

increase pump noise

cavitation occuring

reduce suction pressure

irrregular functioning of the by-

pass

dispense fluid until air is purged from

the by-pass system

Leaks inside system

Immediately switch off pump

and/or disconnect from power

Immediately switch off pump and/or

disconnect from power

A

B

C

11

+49 (6158) 92980-0

Summary of Contents for ABS 200 A-PKW

Page 5: ...b5 b1 b4 l k b7 1 49 6158 92980 0 5...

Page 6: ...f a3 a1 a2 g h h i a4 m c1 n o p 6 49 6158 92980 0 3 2...

Page 7: ...b2 j b6 b3 5 j b6 c2 6 7 5 4 7 49 6158 92980 0...

Page 8: ...1 2 d j e c2 ABS 200 Z PKW i j 8 8 49 6158 92980 0...

Page 9: ...9 2 5 10 7 1 4 3 6 8 6 Spare parts and accessories 9 49 6158 92980 0...