Item No.

Pump model

Nozzle

Flow meter

28 278

ABS 200 A-PKW

auto

-

4. Description

Pump

: Self-priming, volumetric, diaphragm pump, equipped with by-pass valve.

Motor

: Asynchronous motor, single-phase, 2 pole, closed type (protection class IP55 in conformance

with EN 60034-5-86 regulations), self-ventilated.

5. Assembling / Installation

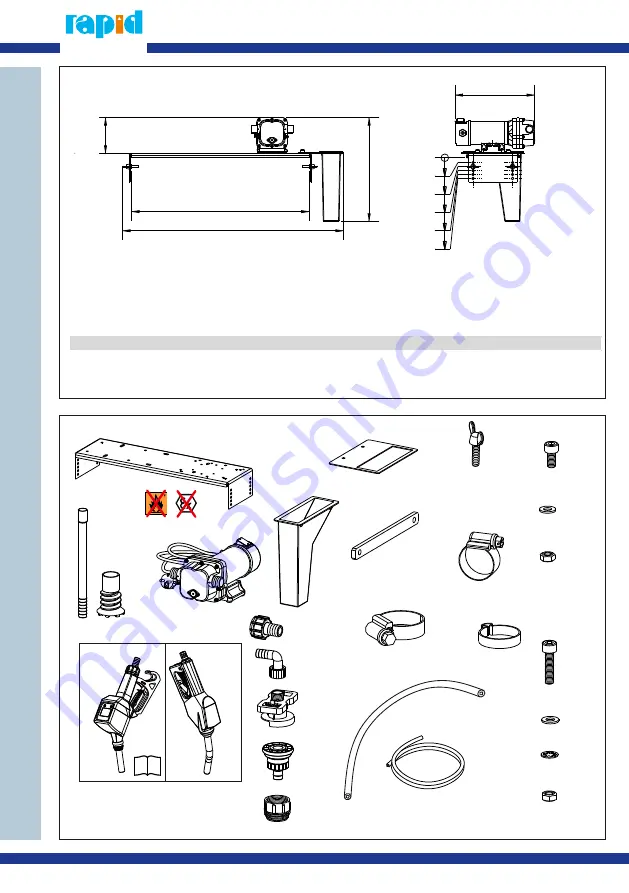

1x a1

1x a2

3x b1

1x a4

4x j

4x f

1x b2

1x b3

1x b4

1x b5

ISO 7380

M5 x 12

2x a3

1x b6

1x e

4x m

4x n

4x o

DIN 912

M5 x 20

DIN 934

M5

DIN 125

A

5,3

DIN 6797

J5,3

4x p

1x d

ABS 200 Z-PKW

ABS 200

A-PKW

i

1x b7

1x l

2x k

2x i

2x g

4x h

DIN 912

M8 x16

DIN 125

A8,4

DIN 980V

M8

ca.262

0

16

29

42

55

68

ca.341

584

ca.1

17

ca.725

1x c1

2x c2

4

+49 (6158) 92980-0

Summary of Contents for ABS 200 A-PKW

Page 5: ...b5 b1 b4 l k b7 1 49 6158 92980 0 5...

Page 6: ...f a3 a1 a2 g h h i a4 m c1 n o p 6 49 6158 92980 0 3 2...

Page 7: ...b2 j b6 b3 5 j b6 c2 6 7 5 4 7 49 6158 92980 0...

Page 8: ...1 2 d j e c2 ABS 200 Z PKW i j 8 8 49 6158 92980 0...

Page 9: ...9 2 5 10 7 1 4 3 6 8 6 Spare parts and accessories 9 49 6158 92980 0...