6

Read the user’s manual carefully before use.

This riveter is equipped with our Multi™ nozzle, allowing you to

set Ø3,2 mm - Ø4 mm - Ø4,8 mm rivets with an unique nozzle.

I. Driving tool requirements

1. The tool must be equipped with

adjustable torque setting

Battery-powered drill or screwdriver that allows you to

choose between several torque positions. The torque is set

by rotating the torque adjustment collar, behind the chuck (Figure

2.F). The higher the torque is, the more force the screwdriver has.

Note: In some cases, the value in Nm is replaced by setting num-

bers (e.g. 1 to 5) where 1 is the minimum torque value and 5 the

maximum.

2.

Minimum battery power required

with cordless driving tool:

• For aluminium, steel and coppered rivets : 12V

• For stainless steel rivets : 14.4V

3.

Driver mode

(

MUST NOT

be in drill mode nor impact mode)

(Figure 2.G)

4.

Always start with lowest speed (RPM)

To do so, set the button with 2 settings to position 1 (when applica-

ble) which is the slowest speed (Figure 2.H). Then, smoothly pull the

trigger and gradually increase until it works well.

II. Features

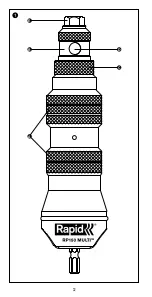

A. Grip areas

B. Front tube

C. Locking ring

D. Inspection hole / Plunger tube

E. Nose piece

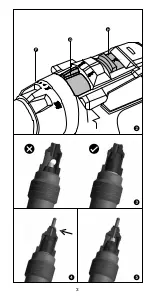

F. Torque adjustment collar

G. Drill/Driver button

H. Speed button

III. Safety guide

1.

Always wear adequate protective gear

, especially ANSI approved

goggles and thick work gloves (Rubber coated).

2. We recommend to only use rivets sold by Rapid. To choose the

best size according to your material thickness, please refer to the

communication on the rivet packaging.

3. The work piece

MUST BE

secured to avoid possible injury. Unse-

cured objects may rotate with the driving tool.

IV. Operating instructions

1. Ensure that everything is

WELL TIGHTENED

before use and be

careful that this remains as it is

BY CHECKING REGULARLY

.

2. You

MUST HOLD

the riveter fi rmly by the grip areas with thick

gloves when using it. The riveter should not rotate.

3. Operate your driving tool

BACKWARD

(anti-clockwise) until an

audible sound comes from the riveter. Confi rm from the inspection

hole on the front tube that the plunger tube inside is at its maximum

forward position (Figure 3).

4. Insert the rivet mandrel into the nosepiece hole and make sure there

is no space between the nosepiece and the rivet fl ange

(Figure 4).

5. Lightly pull the trigger in

FORWARD

(clockwise) direction to have

the mandrel slightly gripped by the riveter, to prevent it from falling

out (Figure 5).

MULTI RIVETER FOR SCREWDRIVER :

RP150 MULTI™

Original instructions

Summary of Contents for RP150 MULTI

Page 2: ...2 A B C D E...

Page 3: ...3 H G F...

Page 4: ...4...

Page 30: ...30 12 14 4 3 2 G 4 1 2 H II C D E F G H III 1 ANSI 2 Rapid 3 IV 1 2 3 3 4 4 5 5 6 7 8 V 1...

Page 31: ...31 VI 1 16 1 8 1 3 VII 5001578 3x...

Page 47: ...47 riveter 3 4 4 5 5 6 7 8 V 1 VI 1 16 1 8 1 3mm VII Art No 5001578 3x...