22

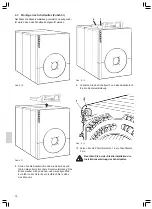

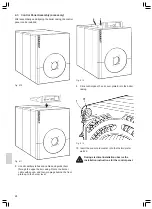

If special building regulations are to be observed,

it may be necessary to construct a base with

sound insulation.

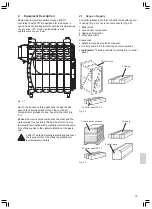

Fig. 3.3

3

Planning Notes

Boilers of type Rapido F220 NT are heat generators for

water heating systems with permissible feed

temperatures of up to 110 °C, i.e. hot water generators of

Group II, as defined by the steam boiler regulation. Such

systems are subject to registration with the competent

trade supervisory board if they are used for industrial

purposes or within the scope of commercial undertakings

and if persons (e.g. caretaker or a housing area) are

employed within its danger area.

Should the above-named criteria not be applicable, it is a

private heating system which must be registered with

and approved by the local building authority.

The heating system must be planned and installed

according to the accepted engineering standards.

The maximum efficiency of the unit should be determined

by a heat requirement calculation for the building

according to DIN 4701 and the heating efficiency for hot

water preparation according to DIN 4708.

Each boiler must be equipped with a component

tested safety valve according to TRD 721.

3.1 Place of installation

During installation the Technical Principles for Planning &

Execution of Central Heating Systems -VDI Guideline

2050, the heating system regulation HeizAnlV, the firing

regulation FeuVo and the regulation BimschV must be

observed.

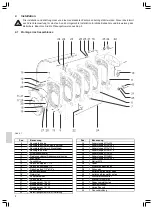

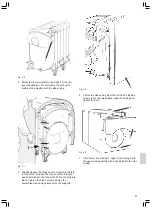

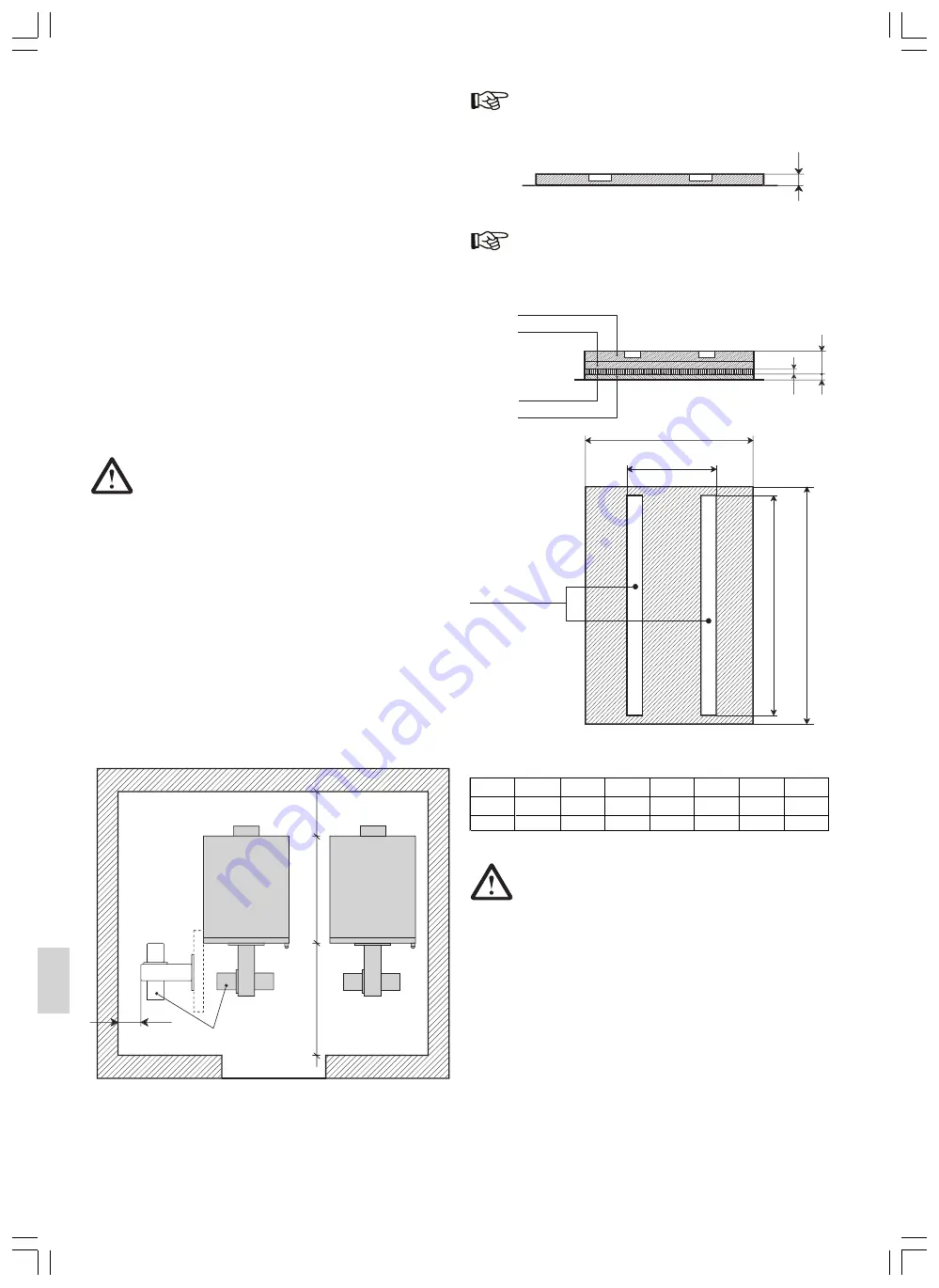

Position the boiler as shown in Fig. 3.1, so that a distance

of at least 100 mm is maintained between the

subsequently mounted blast burner and the wall or a

possibly installed boiler next to it, when the boiler door is

opened.

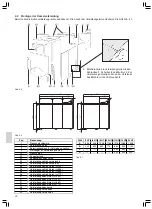

Before assembling the boiler, we recommend that

the customer should construct a boiler base with

integrated flat steel bars (Fig3.2).

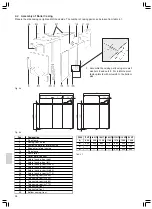

F220

/7 NT

/8 NT

/9 NT

/10 NT /11 NT /12 NT /13 NT

L / mm

1140

1270

1400

1530

1660

1790

1920

A / mm

910

1040

1170

1300

1430

1560

1690

50

Fig. 3.2

If the base has a height between 50 and 80 mm,

one must consider that burners with air suction

nozzles directed downwards require an adequate

distance between suction opening and floor.

850

700

A

L

Flachstahl

Breite 120 mm

Versiegelung

(fakultativ)

Beton

Bewehrung

Schalldämmung

Sockel

80

2

0

2

0

Concrete

Reinforcement

Sound insulation

Foundation

Flat steel bar

Width 120mm

Sealing

(optional)

100

550

T

1500

Brenner

Fig. 3.1

Burner