41

11 Care and maintenance

All oil- or gas-fired appliances must be inspected at least

once a year for correct and economical operation, and

for safety, by a person appointed by the system designer

or other qualified person. Combustion values are to be

checked and, if necessary, readjusted. It is advisable to

take out a maintenance contract. The boiler-room should

be clean, dry and ventilated. The boiler should be

cleaned at certain intervals. Cleaning regularity depends

on fuel consumption, but should take place at least at

the start of each cold season.

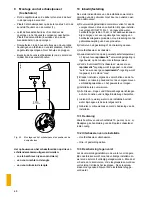

11.1 Cleaning the flue draughts

Disconnect at main switch.

Remove front jacket.

Loosen T-head screws on burner door and lift door.

Pull out radiation converter.

Clean combustion chamber and flue draughts with a

cleaning brush.

Clean remains of burnt fuel from boiler.

Use cleaning access holes in flue gas collector.

Replace radiation converter.

Shut burner door and tighten T-head screws.

Replace front jacket.

Reconnect at main switch and check combustion val-

ues.

11.2 Heating unit water supply

Water quality requirements.

A

Heaters with system capacity of up to 100 kW.

Water with a carbon hardness of up to 3 mol/m

3

(16.8º dH) can be used to fill the system. With harder

water, measures must be taken to avoid furring, using

hardness complexing or water softening.

Heating (circulating) water: applies to open heating units

with two safety pipes, which allow heating water to circu-

late through the expansion chamber. Oxygen binding

chemicals must be added, and sufficient back-flow ex-

cess must be ensured by regular checking. Control mea-

sures relating to heating water composition are not re-

quired for any of the units in this group.

B

Heaters with system capacity of 100 to

1,000 kW.

Water with a carbon hardness of up to 2.0 mol/m

3

(11.2º dH) can be used to fill the system. With harder

water, see reference to water used for filling in A. An in-

hibitor is especially recommended for larger units.