6

6

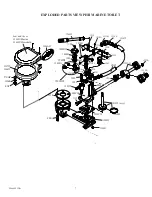

PARTS FOR RARITAN PHII MARINE TOILET

Part No.

Description

1115

3/8"-16 x 1 1/2" Hex Head S/S Bolt(2)

1124

1/4"- 20 x 1/2" R.H. Machine Screw

1200CW

Pump Housing

1201

Intake and Discharge Valve Ball (2)

1202

Intake and Discharge Valve Gasket (2)

1203BW

Intake Valve Body w/"O" Rings,

(Includes 1203B, 1203B1, 1203B2 (2),

1203B3)

1203W

Air Valve Assembly

1204B

Intake Valve Cap

1208W

Retractable Handle

1209BW

Valve Handle

1210

Handle Socket

1210A

Cotter Pin

1210B

Cotter Pin (3)

1211PL

Piston Rod Yoke

1212W

Piston Rod Assembly w/"O" Ring (1232MS)

1214W

Piston Shaft Seal Cartridge Assy

(1214, 1214A, 1214B)

Fits pumps mfg. after 6/92

1216

Clevis Pin (3)

1217

Discharge Valve Cap

1218

Fulcrum Link (2)

1222AW

90° Discharge w/Flange (Std.)

1222B

Straight Discharge (Opt.)

1223B

Flange Nut 3/8"-16 S/S (2)

F098

Housing Screw 1/4"-20 x 1" S/S (4)

1226B

Nut, 1/4"-20 S/S (8)

1228CW

Flapper Valve Assembly (1/2" Holes)

1232MS

Piston "O" Ring

1234

Bowl Gasket

1236E

Bowl Elbow

1248W

Base w/Plug

1249

Base Plug (not shown)

221361

Washer- Inlet Adapter

C253

Joker Valve

CH42

Hose (¾" I.D.)

CH43P

Hose Clamp (2)

F005

1/4"- 20 x 5/16" S/S Socket Set Screw

F081

Bowl Bolt 1/4"-20 x 2 S/S Hex head

LWS

Intake and Discharge Valve Spring (2)

RNI

Nylon Shoulder Washer

RARITAN INSTALLATION ACCESSORIES

Part No.

Description

163000

In-Line Strainer

1PCP32

C.P., Cleans Potties, Bio-enzymatic, 32 oz.

SFH

Sani-Flex Hose 1 ½"

SFH1

Sani-Flex Hose 1"

SL1CC

Super Lube 1cc tube

KO2

Knocks Out Odor Kit

BOWL & SEAT

Part No.

Description

1236AW

Spud assy.

1237W

Marine-size Bowl assy. (includes 1236AW)

1244W

White Household-style Bowl assy.

(includes 1236AW)

1238SC

Marine-size seat & cover; Slow Close

1245SC

Household-style seat & cover; Slow Close

VCAP

Vinyl Cap

OVERHAUL KITS

Part No.

Description

PHRKIIU

Universal Repair Kit

PHIIPUMP

PHII Pump replacement assembly

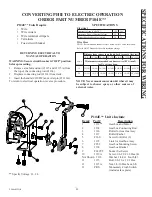

ELECTRIC CONVERSION KIT

P104E12

12 VOLTS

P104E24

24 VOLTS

PAR

TS LIST

L584v0222jlc