4

This heater shall not be installed in a “confined” space or unusually tight construction unless provisions are

provided for adequate combustion and ventilation air.

Calculations to Determine Confined or Unconfined Space:

1. Determine number or rooms (including adjoining rooms with odorless passageways or ventilation grates.)

Example: Living room/Dining Room +

Kitchen

2. Determine the Total Volume of the Space (Width x Length x Height).

Example: Living room/Dining Room 14’ x 20’ x 8’ = 2240 cu ft.

Kitchen

8’ x 12’ x 8’ = 768 cu ft.

Total Volume of Space

3008 cu ft.

3. Divide the total volume of space by 50 cu ft to determine the Maximum Supportable Btu/Hr.

Example: 3008 cu ft ÷ 50 = 60.160 x 1000 = 60,160

Maximum Supportable Btu/Hr. = 60,160 Btu/Hr.

4. Add the rated (Btu/hr) of all fuel burning appliances in the “space” to determine Actual Btu/Hr. used.

Example: Vent free gas log heater 40,000 Btu/Hr.

+ Gas water heater 32,000 Btu/Hr.

= Actual Btu/Hr. Used 72,000 Btu/Hr.

Note: Do not include direct vent gas appliances.

5. Compare Maximum Supportable Btu/Hr to Actual Btu/Hr Used.

• If the Actual Btu/Hr used. is greater than the Maximum Supportable Btu/Hr. then the space is CONFINED.

• If the Actual Btu/Hr used. Is less than the Maximum Supportable Btu/Hr. then the space is UNCONFINED.

Example:

Maximum Supportable Btu/Hr = 60,160 Btu/Hr.

Actual Btu/Hr. Used = 72,000 Btu/Hr.

Difference

= 11,840 Btu/Hr. = Excess Non-Supportable Btu/Hr.

Because the Actual Btu/Hr used Exceeds the Maximum Supportable Btu/Hr in this example, the space is considered

a Confined Space requiring you to either increase the Maximum Supportable Btu/Hr by the difference, in this case

11,840 Btu/Hr. or decrease the Actual Btu/Hr used by the same amount. You may also choose to operate your

ALTERNA™ as a Vented Appliance instead. (See notes and warnings regarding vented installation on Page 7)

Adequate Combustion And Ventilation Air Options:

•

Increasing the Maximum Supportable Btu/Hr.

1. Add to the number of rooms which comprise the “Space”. To do this you must either completely remove the door

to an adjoining room, or provide two permanent ventilation grills; one within 12” of the ceiling and another within

12” of the floor.

2. Provide extra fresh air using ventilation grills and ducts to the outdoors. You must provide two permanent open-

ings. One within 12” of the ceiling and another within 12” of the floor. Connect these directly to the outdoors or

spaces open to the outdoors, e.g., attics or crawl spaces. If this route is chosen you MUST follow the National

Fuel Gas Code NFPA 54/ANSI Z223.1, Section 5.3, Air for Combustion and Ventilation for required size of

ventilation grills or ducts.

•

Lower the Actual Btu/Hr used by relocating other gas burning appliances outside the “space” or installing a lower

Btu/Hr heater. In the example, the maximum Btu/Hr. of the heater could be no more than 28,160 Btu/Hr.

The “National Fuel Gas Code, ANSI Z223.1/NFPA 54” defines a confined space as a space whose volume is less than

50 cubic feet per 1000 Btu per hour (4.8 m

³

per kW) of the aggregate input rating of all appliances installed in that space

and an unconfined space as a space whose volume is not less than 50 cubic feet per 100 Btu per hour (4.8 m

³

per kw) of

the aggregated input rating of all appliances installed in that space. Rooms communicating directly with the space in

which the appliances are installed, through openings not furnished with doors, are considered a part of the unconfined

space.

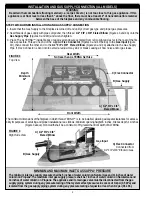

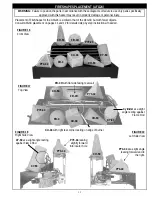

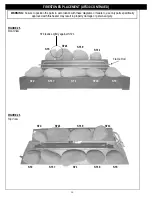

VENT FREE APPLICATIONS

●

SPACING CALCULATIONS