9

ALL APPLICATIONS (VENTED and VENT FREE OPERATION)

LIGHTING and OPERATION

Control Locations and Description

All Models (C9-S-R)

•

Primary Gas Valve Control Knob (Switch

Models):

Pilot Lighting and Valve gas output

adjustment from OFF to FULL.

See Figure 7

•

Switch Models (C9-S) 3 Way Selector Switch:

Mode selections: SWITCH ON, OFF REMOTE

ACCESS ON.

See Figure 6.

•

Switch Models (C9-S) Piezo Ignitor Button:

Pilot Flame Ignition.

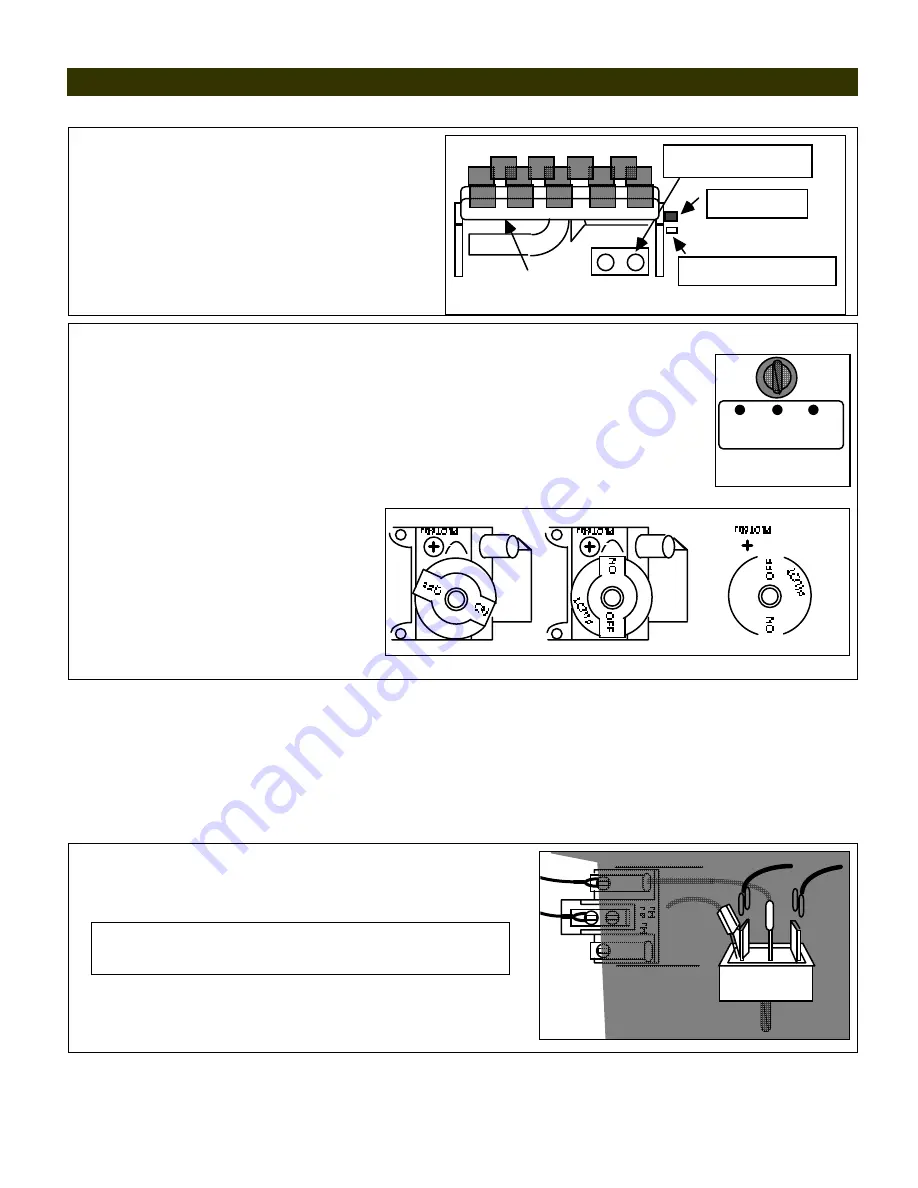

Figure 4

3 WAY SELECTOR SWITCH

(Switch Models Only)

PIEZO IGNITER

BUTTON

Pilot Position

PRIMARY GAS VALVE

CONTROL KNOB

C9-S (Switch Control) LIGHTING and OPERATION

Pilot Lighting:

1. Depress and turn the

Primary Gas Valve Control Knob

(located at the base of the right

rear grate leg, clockwise to the

"OFF"

position.

See Figures 4 and 7.

2. Place the

3 Way

Control Selector Switch

in

OFF (Fig 6)

. Turn off all Remote

Accessory Controls (Switch or Hand Held Remote) or place Thermostat to lowest setting.

3. Wait at least 5 minutes prior to lighting

4. Depress and turn

Primary Gas Valve Control Knob

counter clockwise to the

"PILOT"

position. (

Figure 7

)

SWITCH OFF REMOTE

ON ACCESS

ON

3 WAY CONTROL

SELECTOR SWITCH

Figure 6

5. Depress fully and hold in the

Primary

Gas Valve Control Knob

until all air is

bled and gas flows to pilot.

6. Press

Piezo Ignitor Button

(Figure 3) to light pilot. Continue to hold

in

Primary Gas Valve Control

Knob

until the Pilot flame remains lit when knob

is released (approx 60 to 90 seconds). If

Pilot does not remain lit, repeat steps

1.

through

5.

and allow additional time after

Figure 7

"ON" POSITION

+

+

v

+

+

PILOT

+

v

+

+

PILOT ADJUST COVER CAP

lighting Pilot before releasing knob.

Switch Control (Manual ON-OFF):

After successful pilot lighting, allow 60-90 seconds for the Thermogenerator to heat up. To turn burner on, place

Control Selector Switch

in the

"ON"

position (

see Figure 6

). To turn burner off (pilot remains lit) place

Control Selector Switch

in the

"OFF"

position.

NOTE: Flame size at the burner is adjustable at the

Primary Gas Valve Control

Knob

(

see Figure 7

).

Shutdown

:

For complete shutdown (including Pilot), place

Control Selector Switch

in the

"OFF"

position

and push

Primary Gas Valve Control

Knob (Fig 7)

in and turn fully clockwise to “

OFF

”.

Switch Accessory Wiring:

Wiring from the Accessory Control (Remote, Thermostat or

Switch) is connected to the two

outside terminals

of the

Control Selector Switch

as shown.

NOTE:

Wire length for Thermostat or Remote or controls

should not exceed 20 feet. Thermostat wiring should be 20

AWG Type CL2.

Switch Accessory Operation:

Place manual switch in the

"

REMOTE ACCESS ON

" position. Burner "

ON

" or "

OFF

" is

now controlled by the position of the accessory control being

used with the burner.

From THERMOPILE

Valve

Terminals

3 Way Control Selector Switch

To ACCESSORY CONTROL

Outside

Terminal

Piggy

Back

Outside

Terminal