23

NORMAL OPERATING CHARACTERISTICS

Each and every

ALTERNA™

that leaves the factory is quality checked to ensure compliance with our

certification. This

check includes an operational test to ensure both satisfactory combustion and proper operation.

Each installation site for any vent free heater presents its own unique combustion environment. Specific factors such

as weather tightness of the home, size of the room in which the heater is installed, central heating, ceiling fans, drafts,

altitude, the size of the firebox, paint or soot inside the firebox, etc., all have an influence on the proper operation of

any vent free gas heater.

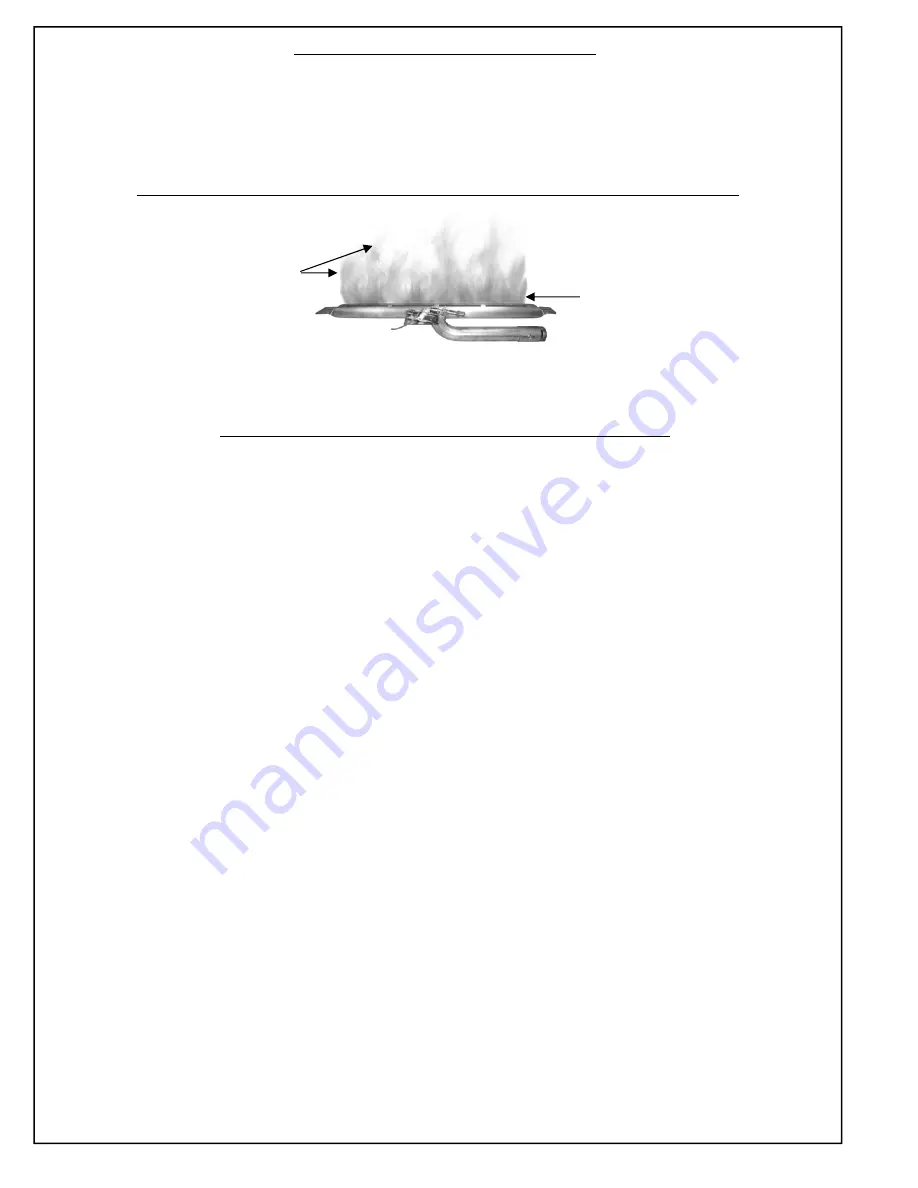

A normally operating ALTERNA™ Gas Fire Set possess the following characteristics:

•

Clean burning combustion, which, after normal break in, will produce no soot or smoke.

•

A full bodied, lively flame. The flame will be blue at the base and a combination of blue and yellow at the body and

tips.

•

After initial break-in produce no odor other than the normal odors associated with the combustion of Natural or Pro-

pane gas and/or the environment in which the heater is operated.

•

Will produce water vapor (increase indoor humidity) which may be beneficial during the dry heating season.

CUSTOMER RESPONSIBILITIES AND PERIODIC MAINTENANCE

•

Keep the area around the

ALTERNA™

free and clear from debris. From time to time, visually check pilot and burner

flames for proper appearance (see section above for burner; see Page 20 Fig. 34 for Pilot).

•

Periodically examine and clean the venting system. Once every year, a qualified agency or certified chimney sweep

should examine and clean the venting system of the solid fuel burning fireplace in which the ALTERNA™ installed (if

applicable).

•

The air shutter and burner must be free of lint and dirt for optimum performance. Air shutters which have been closed

or are obstructed with debris will not allow sufficient combustion air into the burner. Air shutters and burner ports

(where flame comes out of the burner) should be periodically cleaned of debris. Use compressed air and/or a soft

bristle brush to clean burner ports and air shutter area..

Air shutters should not be altered from factory settings

.

WARNING: Failure to keep the burner primary air opening clean may result in sooting or property damage.

•

Keep air intake holes of ODS Pilot (see Page 20 Figure 34) clear of lint. Over time lint will accumulate in these holes,

and will eventually result in nuisance pilot outage or difficulty in lighting pilot. Clean these holes annually with

compressed air or a pipe cleaner.

NOTE: Lint and dust in the Air Intake Holes is the #1 cause of nuisance pilot

outage.

•

Do not operate in a dirty firebox or in a previously used firebox which has not had all soot completely removed or

chimney flue cleaned. Previously used fireboxes must have flue and stack professionally cleaned by a chimney

sweep. Additionally, firebox walls and damper must also be thoroughly cleaned of all burn residue and soot using a

damp cloth, sponge or brush.

•

Do not operate this set with any burner objects other than the

RASMUSSEN

FireBalls, FireShapes or FireStones

specifically designed and approved for use with this Burner System.

•

Do not use with blower inserts or heat exchangers.

•

If used, glass doors must be wide open when burner is on.

•

Do not remove Rating Plate/Warning Tags. These tags serve you and any future user as an integral safety and

identification component of the

ALTERNA™

gas log heater.

Removing these tags voids the warranty.

•

WARNING:

Do not allow fans to blow directly into fireplace. Avoid any drafts that alter burner flame patterns.

Do not place blower inside area of firebox. Ceiling fans may create drafts that alter burner flame patterns. Sooting and

improper burning may occur. Sooting can settle on surfaces outside the fireplace.

•

During periods of heavy use, inspect frequently for evidence of sooting. If sooting is present, discontinue use until

source of sooting is determined and corrected.

•

Maintain positioning of FireBalls, FireShapes or FireStones (Pages 9 thru 18)

at all times.

•

Occasionally, you may use a soft bristle brush or damp cloth to clean objects.

Blue

Blue and Yellow