EN

11

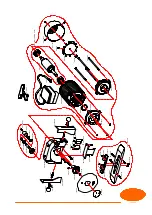

If the blade is no more able to cut (even after repeating

the sharpening operation several times) it is necessary to

replace it. To carry out this operation, use butterfly wrench

“1” (shown in picture 8).

To replace the blade, proceed as follows:

1) Use some protective gloves in compliance with

Italian Legislative Decree 81/08.

2) Remove the two adjusting knobs “A” and “D” of

the right and left protection covers “C” and “F” by

removing the two relative washers “B” and “E”

(see picture 9).

3) Unscrew nut “G” by using the butterfly wrench “1”

and remove blade “H” (see picture 10).

4) Replace the worn blade with the new one “2”,

being careful to center the blade on the gear, in

the correct position; we remind you to assemble

it so that the side with the writing Rasor can be

seen by the operator.

6) Assemble all the components again and carry out

the sharpening.

13. BLADE REPLACEMENT

9

D

8

10

E

F

A

B

C

H

1

G

2

1