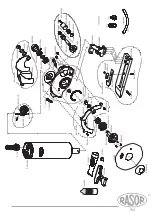

P179

FP01

3C

PL

SW

1290M

SW

12

90

M

C

P

L

SW

1262

01-1P

SW

1239

00

S

W

127

502

S

W

1276

00

S

W

127

500

SW

12

7501

SW

10

8000

SW

10

8200

SW

10

8100

S

W

121

801

C

PL

-1P

SW

1262

01-1P

S

W

121

800-1P

T

1018

01

S

W

1238

00

S

W

1093

00

SW

10

9200

SW

10

9000

S

W

128

6C

P

L

SW

10

9100

SW

12

5600

SW

10

4102

S

W

104

103

SW

12

4100

S

W

124

1C

PL

S

W

1241

01

SW

12

6103

SW

12

4101

12

SH

SS

T1

045

01

T1

045

01

T1

05400

T

10

5200

SW

12

7201

T1

04700

S

W

1244

C

P

L

T

10

5300

S

W

126

101

SW

1255M

SW

12

4402

S

W

124

400

T10

4800

SW

10

8800

S

W

108

900

SW

10

8700

SW

12

8600

S

W

124

000

SW

10

76S

SW

10

7900

SW

12

7201

SW

12

6102

S

W

1263

00

SW

1241

02

T

107

600

T

10

7900

T

10

7500

T 107905