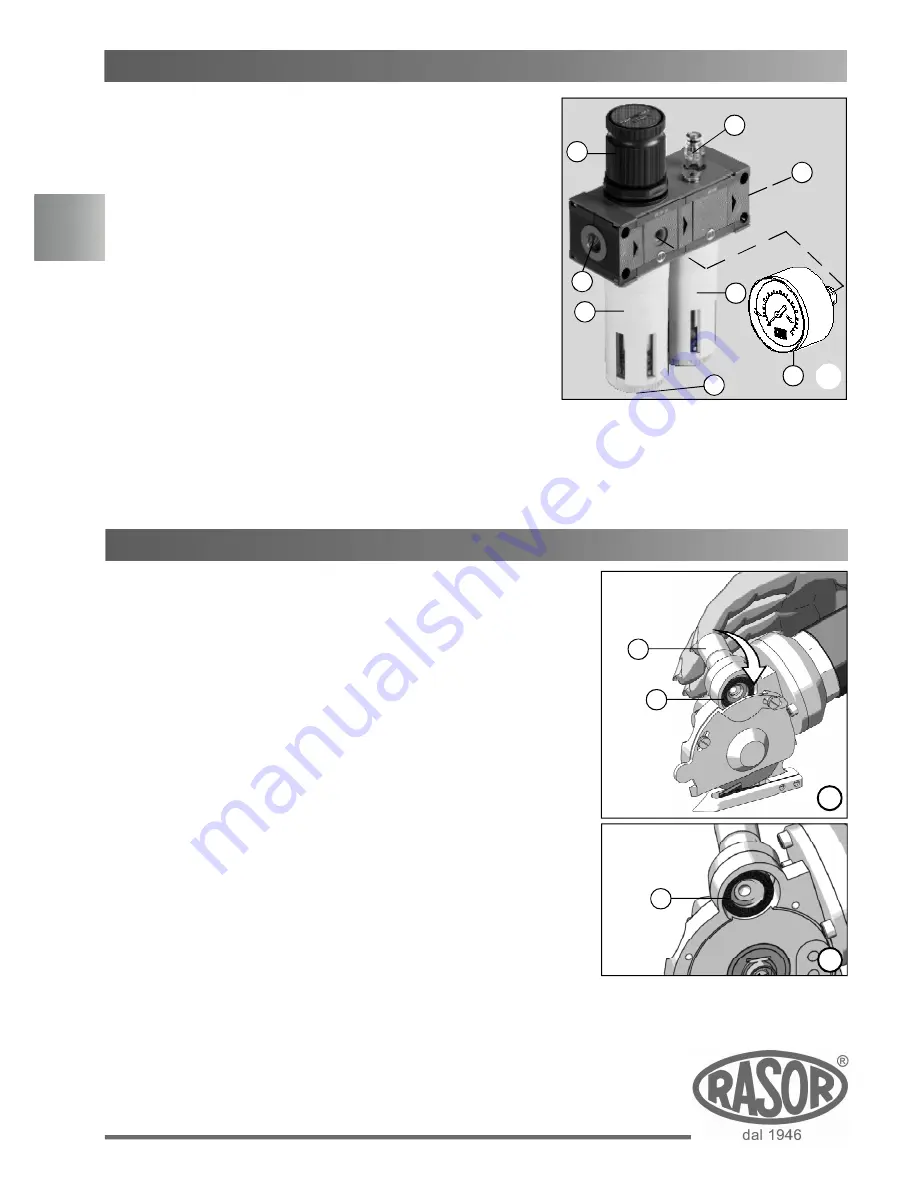

11. AIR PRESSURE GAUGE (OPTION)

7

The pneumatic scissors must be necessarily fed with

lubricated air with a pressure of 4-6 bar.

Rasor

®

offers, as option, a reduction unit filter with a

pressure gauge already calibrated with the quantity

of oil to be delivered.

The unit shown in picture 7 is made up of:

1 - pressure reducer;

2 - valve to drain the condensate;

3 - drip-feed oiler unit;

4 - oil tank;

5 - pressure gauge;

6 - condensate tank;

7 - pipe fitting to connect the quick connection to

the network;

8 - pipe fitting to connect the quick connection to the scissors.

For the use and maintenance read the instruction sheet supplied with the filter.

5

1

2

3

4

6

7

8

12. BLADE SHARPENING

After many hours of a continuative use of the pneumatic

scissors or if they are not able to cut anymore, it is necessary

to sharp the blade.

To carry out this operation, start the blade and press emery

grinding wheel “2” on the same one (by pressing sharpening

button “1” as shown in picture 8) for 3-4 seconds. Repeat

this operation 2-3 times.

If the sharpening process should be ineffective, check the

wear of the emery grinding wheel “3” (see picture 9). If

wheel “3” is too worn or dirty, replace it by removing the

blade by means of the proper tool.

8

1

2

9

3

EN

26