6

EN

4. PRODUCT DESCRIPTION

The fixture described in this manual is a pneumatic cutting unit model FP861V2 which can

be assembled on automatic machines (e.g. spreaders, computerized cutting, etc...) by means

of a proper bracket. By cutting with the blade and the counterblade always in contact and

thanks to the steel upper quality of the blade supplied, FP861V2 guarantees the clean

separation without frayings of the two borders of the cut material. The motor, extremely

compact dimensionsand extreme reliability, is positioned vertically, perpendicular to the

cutting direction, and, with special 86 mm diameter blades, guarantees cuts with thickness

up to 2.5 cm. The high torque and the slow speed of the knife allow the cutting of rubber

material with plastic base in the carpet and light flooring application.

One special feature of cutting FP861V2 is its ability to sharpen the blade in each moment

without disassembling it by means of a grinding wheel mounted on the cutting unit head.

After carrying out this operation, it is possible to start cutting again. The unit is provided

with a threaded connection to the majority of the air pipes. The turbine, perfectly balanced,

with a high number of revolutions and totally free of maintenance, reduces the vibrations

and the noise to the minimum. The cutting unit can be used to cut damp or wet materials

and therefore particularly recommended in tannery, dyeworks, etc... The use of compressed

air as source of energy allows working continuously without problems of heating or motor

overload. The mechanical parts are made up of steel, high resistant bronze and aluminium

and require a lubrication after many working hours.

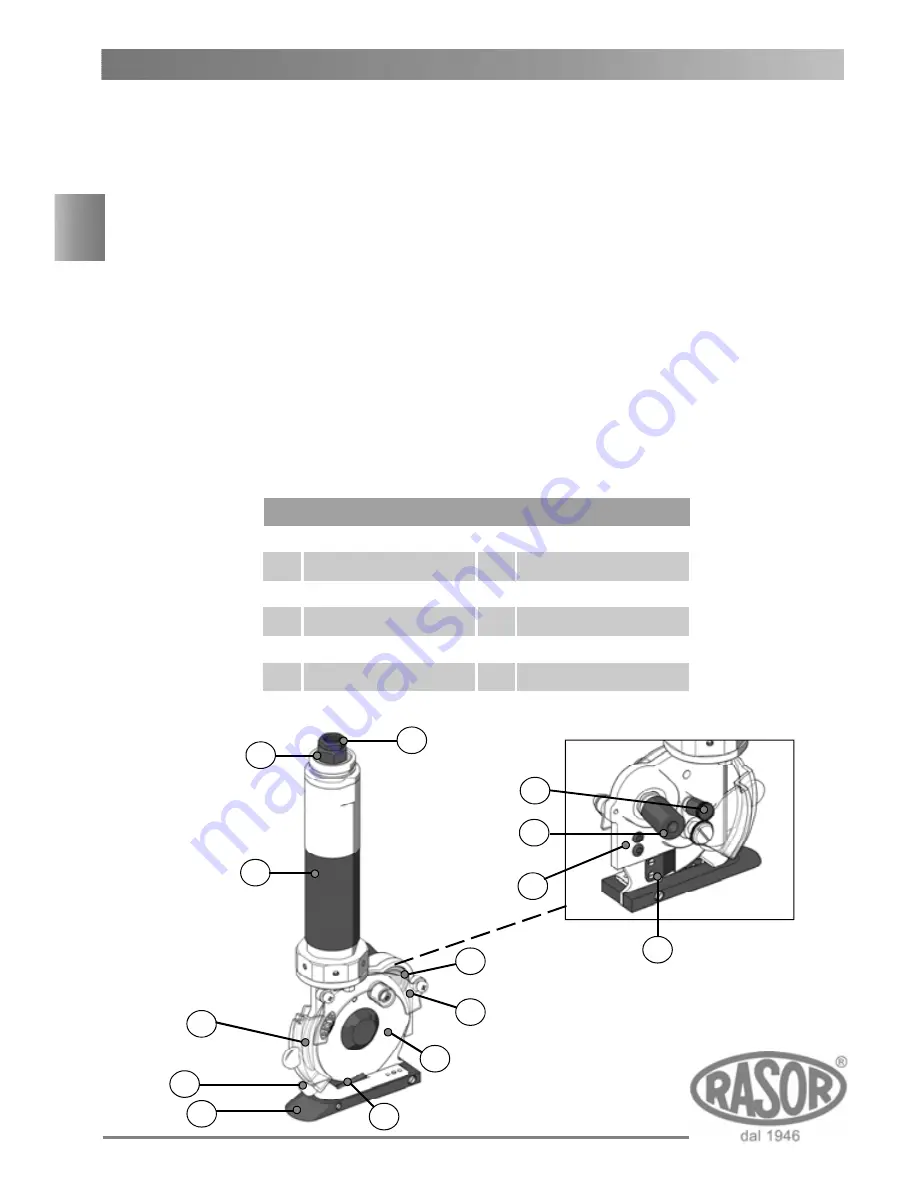

1

8

6

3

11

4

12

2

9

5

7

14

13

10

1

1/4" gas connection for the air

connector

8

Polygonal blade

2

Silencer

9

Fixed rear guard

3

Pneumatic motor

10

Sharpener

4

Mobile front guard

11

Greaser

5

Reference drift

12

Sharpening push button

6

Aluminum base covere with

Teflon

13

Motor support

7

Hard metal counterblade

14

Spring locking the thread

Device components