EN

9

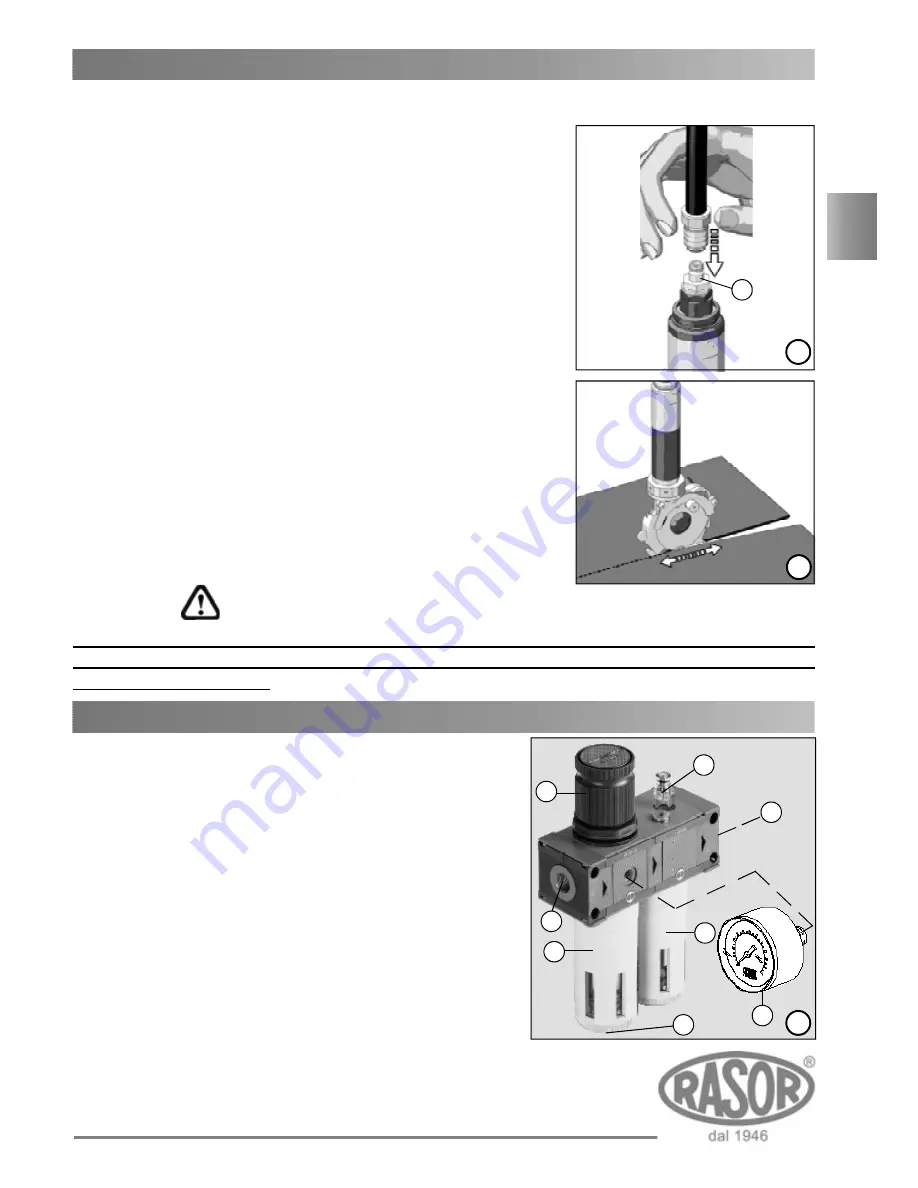

10. INSTALLATION AND USE

To install and use the cutting unit do as follows:

1) Fix the cutting unit to the machine by means of a flat

or angle bracket to mount on the upper part of the

motor support of the unit.

NOTE

The cutting unit can be installed in any position or angle:

vertical, uside down, lateral. The aluminium base does not

have to touch the machine table.

2) Lay down the material to be cut;

3) Connect the air hose to quick connection “A” (not

supplied) (see picture 4);

4) Set the pressure gauge (option) to 6 bar;

5) Put the material on the cutting base (see picture 5);

6) Adjust the moving front protection according to the

thickness of the material to cut;

7) Enable the air remotely and carry out the cutting

operation.

NOTE

It is possible to use cutting unit FP861V2 both keeping it

fixed and making the material slide and viceversa. It is

important to keep the material to cut as stretched as possible

to prevent it from curling

WARNING

Do not use the two bolts which connect the motor to the cutting part to fix

cutting unit FP861V2, otherwise the motor shaft could break. In this case the

warranty will be void.

4

5

11. AIR PRESSURE GAUGE (OPTION)

The cutting unit must be necessarily fed with lubricated

air with a pressure of 4-6 bar.

Rasor

®

offers, as option, a reduction unit filter with a

pressure gauge already calibrated with the quantity of

oil to be delivered as option.

The unit shown also in picture 6 is made up of:

1 - pressure reducer;

2 - valve to drain the condensate;

3 - drip-feed oiler unit;

4 - oil tank;

5 - pressure gauge;

6 - condensate tank;

7 - pipe fitting to connect the quick connection to

the network;

8 - pipe fitting to connect the quick connection to the scissor.

For the use and maintenance read the instruction sheet supplied with

the filter.

5

1

2

3

4

6

7

8

6

A