6

EN

4. PRODUCT DESCRIPTION

The fixture described in this manual is a bench cutter model SW100 which is used in order

to cut strong fabrics. By cutting with the blade and the counterblade always in contact and

thanks to the steel upper quality of the blade supplied, SW100 cutter guarantees the clear

separation without frayings of the two borders of the cut material. The fixture is extremely

versatile, light and precise in the cutting operation. Thanks to the use of a sliding bearing

base and an effective cutting system with a poligonal blade, it is possible to use the bench

cutter to cut curved profiles not only in the textile and tannage sector, but also in several

industrial sectors such as to cut polymers, thermoacoustic insulators, padding, neoprene,

filters, synthetic fabrics and similar fabrics, moquette and internal parts of cars and ships.

The blade diameter (100mm) and the small weight (3Kg) make this bench cutter the ideal

fixture for cuts with small radius of curvature and with thickness up to 3,5 cm. The wide

sliding bearing base allows the operator to slide the cutter on the table without efforts. A

sharpener assembled on the cutter heads allows whetting the blade at any moment without

disassembling it. After carrying out this operation, it is possible to start cutting again. A high

power motor, perfectly balanced, with a high number of revolutions and totally free of

maintenance, reduces the vibrations to the minimum, thus making the bench cutter complies

with Legislative Decree No.

187 dated 19/8/2005, which adopts European Directive No.

2002/44/CE concerning the risks deriving from mechanical vibrations.The mechanical parts are

made of high quality steel, bronze and aluminium and require lubrication after several working hours.

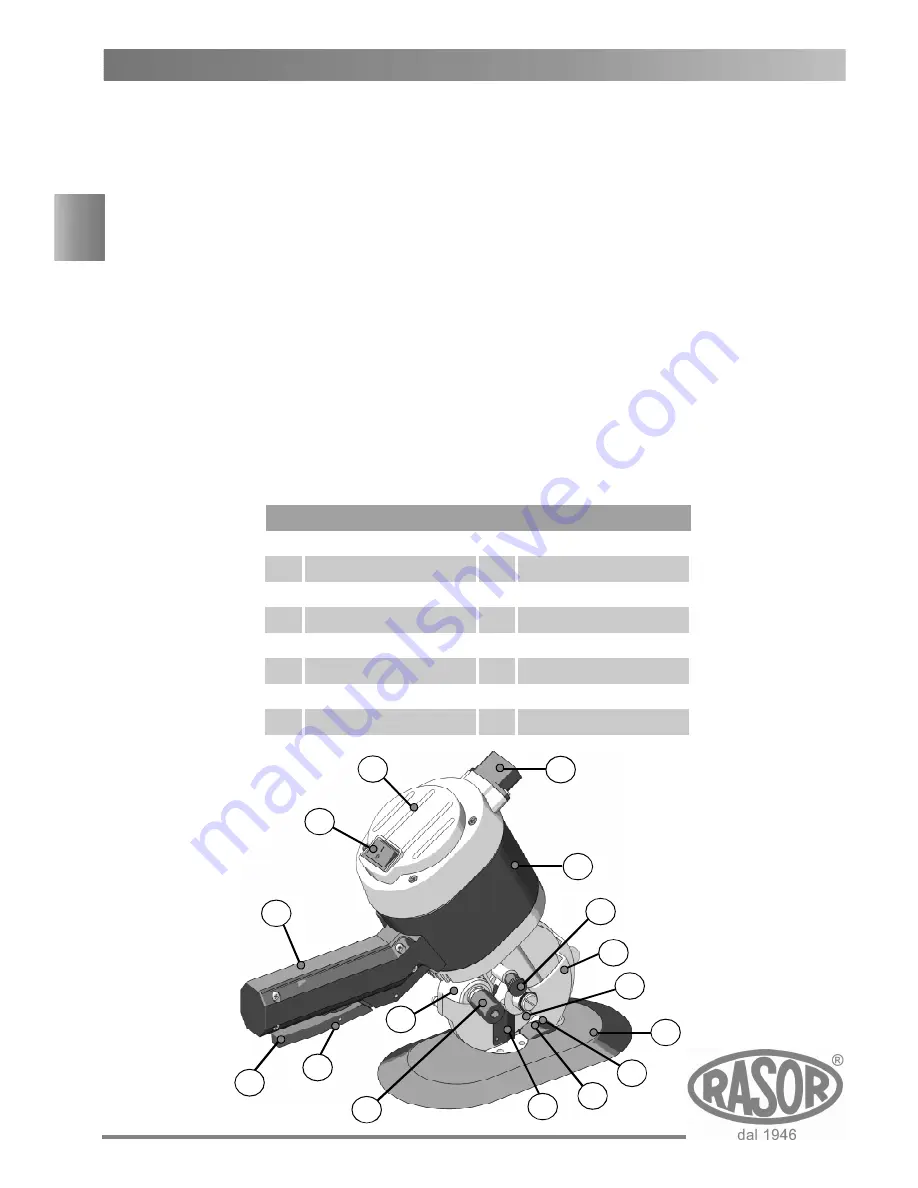

1

2

3

4

11

7

8

10

5

6

12

13

14

15

9

16

1

Switch provided with light

9

Poligonal blade

2

Motor cover

10

Plate blocking the threads

3

Connector socket

11

Greaser

4

Motor frame

12

Safety catch to enable the starting

lever

5

Sharpener push button

13

Control lever

6

Motor support

14

Handle

7

Movable front protection

15

Complementary foot

8

Roller platform covered with

Teflon

®

16

Counterblade

Device components