37

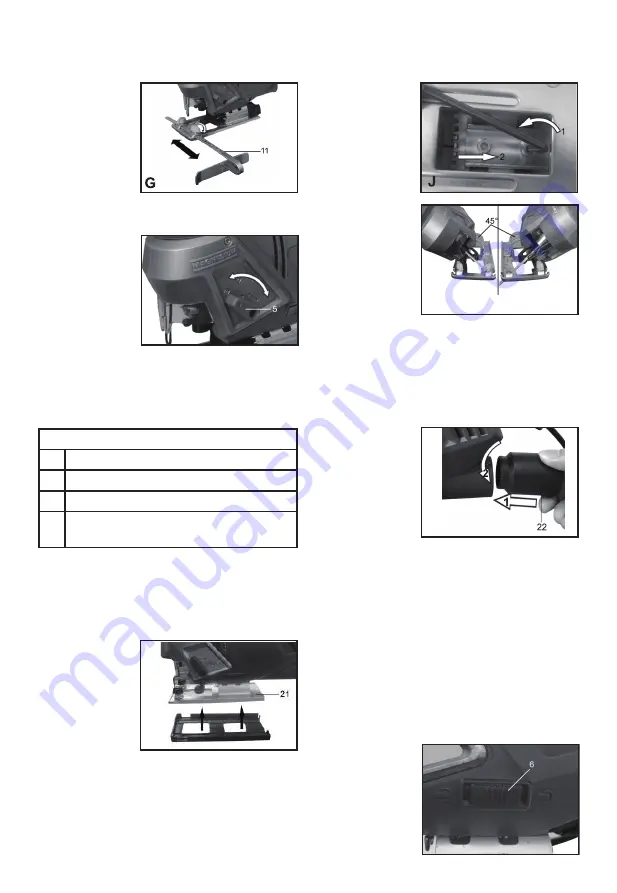

tighten both screws to lock into position. (See G)

8. ROLLER GUIDE

Ensure the blade

is located and

runs smoothly in

the groove. (See

F) Otherwise the

pendulum function

will not work

correctly and the

blade will not be supported during cutting.

9. PENDULUM

ACTION

CONTROL

The pendulum

action varies the

forward cutting

angle of the blade

for increased

cutting efficiency. This can also be adjusted

during no load running. Refer to the chart 2 for

more details. Do not use excessive blade force

when cutting with the pendulum action. The

blade cuts on the upward stroke only (See H).

Chart 2

0

Thin materials. Fine cuts. Tight curves.

1

Hard materials, (e.g. steel & chipboard)

2

Thick materials (e.g. wood) & plastic

3

Fast cuts (e.g. softwood). Cutting in the

direction of the wood grain.

10. ANGLE PLATE

Adjusting the angle of the base plate enables

bevel cutting. The base plate must always be held

firmly against the materials being cut to reduce

saw vibration, blade jumping or blade breakage.

11. PLASTIC

FOOT PLATE

PROTECTION

(See I)

Your tool is

equipped with

base plate

protection that protects finer surface.

To attached, hook the protection over front of

base plate and snap into base plate.

12. BASE PLATE ANGLE ADJUSTMENT (See

J, K)

Use a hex key (3). First loosen the bolts securing

the base plate

and pull the base

plate out of the

slots (See J). For

preset angles

rotate so the lines

of the angle on

the base plate

and angle plate

(9) superposition

at the desired

angle (0, 15, 30,

45) (See K). For

other bevel angles,

rotate to your

desired angle (use

a protractor scale). Following one of the above

procedures, hold the base plate in position and

firmly tighten the bolts to clamp the base plate at

that angle. Finally, check the angle and ensure

the base plate is firmly clamped. The angle

markings on the base plate are accurate for

most general purposes but it is recommended for

accurate work to

set the angle with

a protractor and

make a test cut on

other material.

13. VACUUM

ADAPTER

The adapter (22) rotates anti-clockwise inside the

housing and locks in position by a groove inside

the housing (See L). The adapter must then be

connected to a suitable external dust extraction

machine.

14. PROTECTION FINGER

The finger is located in front of the blade holder.

Whilst working, it will help prevent accidental

contact with moving blade.

15. DUST BLOWER SWITCH (See M)

The sawdust blower device leads an air jet to the

saw blade. The air

jet avoids sawdust

from covering the

cutting line during

operation.

The sawdust

vacuum device can

I

K

M

L

H

Summary of Contents for CR800M

Page 14: ...14 DESPIECE 7993X117 CR800M...

Page 28: ...28 Cat logo de pe as sobressalentes 7993X117 CR800M...

Page 40: ...40 EXPLODED VIEW PARTS DRAWING 7993X117 CR800M...

Page 42: ...42...

Page 43: ...43...

Page 44: ......