12 | Initial start-up

80.06.083_iCombiPro-iCombiClassic_IM_en-US

85 / 96

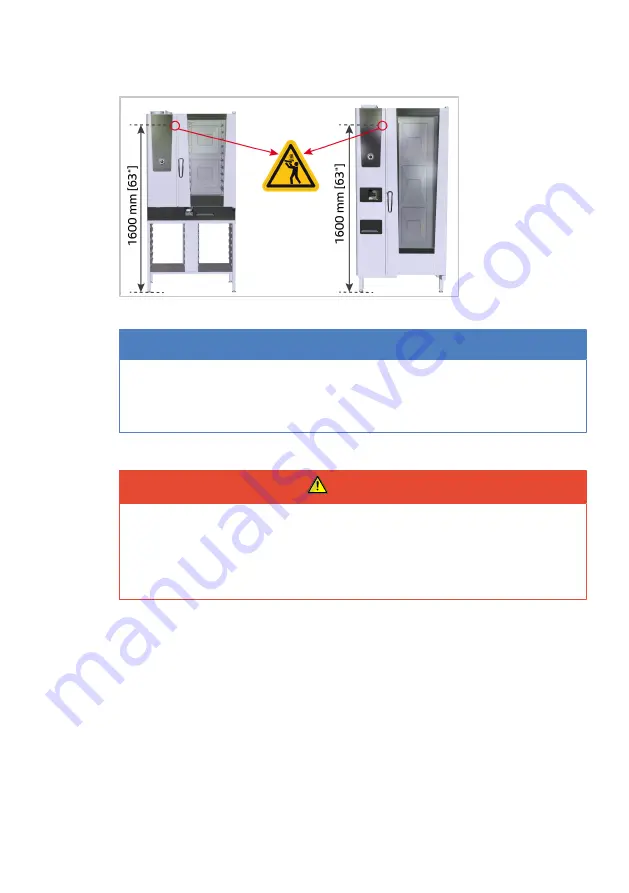

After installing the device, attach the 1600 mm [63 inch] maximum insertion

height sticker to the device. The sticker is included with the starter kit.

Run software update

NOTE

Run software update

Always carry out a software update for commissioning. This means that your

device will start with the latest software version.

12.2 Performing a self test

DANGER

Changed CO / CO

2

values after self test

Risk of poisoning due to excessive flue gas values.

n

Perform a flue gas analysis after the self test.

n

Set the values according to the flue gas analysis specifications.

The self test must be started once when the device is first commissioned. Dur-

ing the self test, the device is adapted to the ambient conditions.

The self test runs automatically. The duration depends on the device size and is

between 45 and 65 minutes. With an UltraVent extractor hood, the self test is

extended by approx. 20 minutes.

Preparations

n

The device is properly connected to water, wastewater, electricity and, for

gas devices, to the gas supply and flue gas system as described in these in-

structions.

n

Check that the hook ladders and the air baffle are correctly fitted.

n

The left side wall is closed.

n

One GN container per fan wheel is required for the self test.

Summary of Contents for iCombi Pro

Page 1: ...iCombi Pro iCombi Classic CombiMaster Plus Original installation instructions...

Page 93: ......

Page 94: ......

Page 95: ......