Summary of Contents for SelfCookingCenter series

Page 1: ...Original operating instructions SelfCookingCenter...

Page 27: ...Overview of the cooking modes 27 72...

Page 68: ...EU Declaration of Conformity for electrical appliances 68 72...

Page 69: ...EU Declaration of Conformity for electrical appliances 69 72...

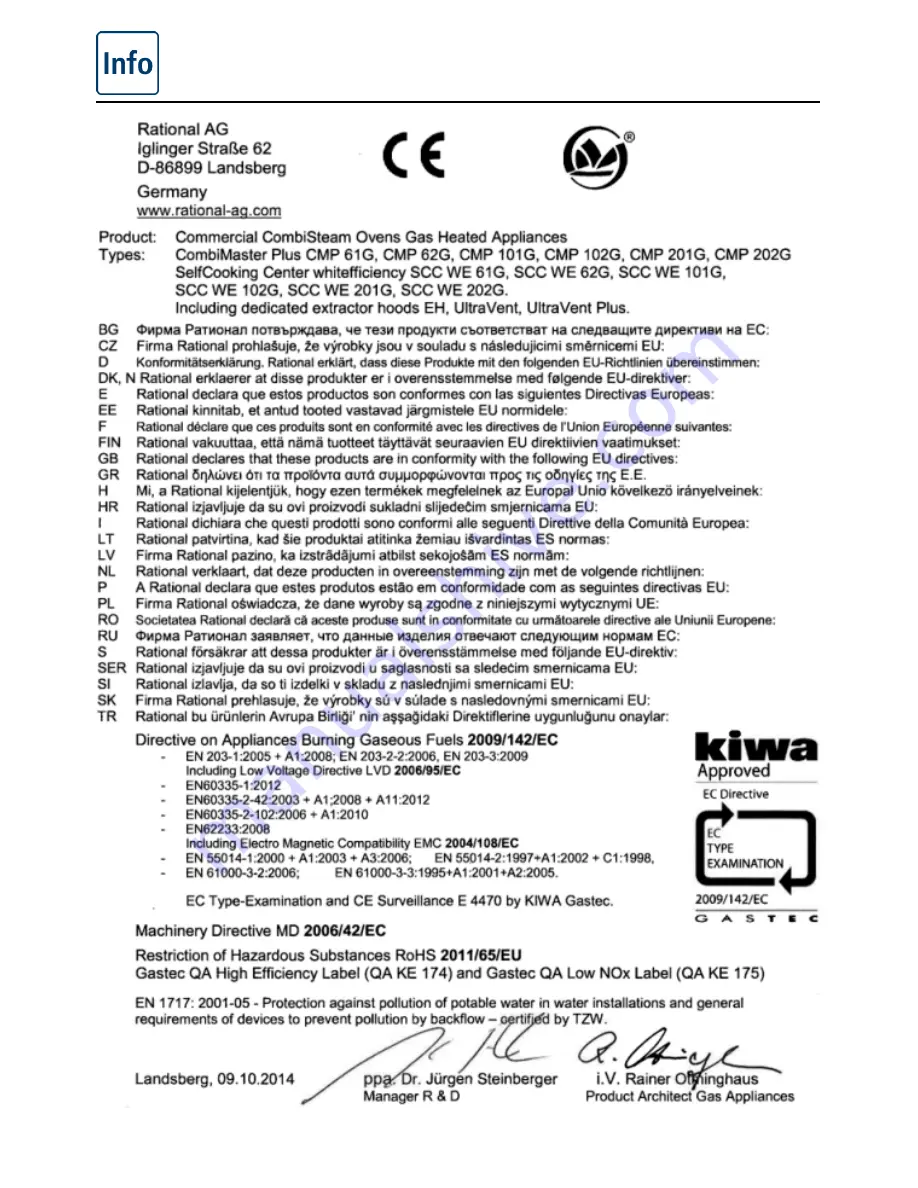

Page 70: ...EU Declaration of Conformity for gas appliances 70 72...

Page 72: ...80 05 762 V 02 MDS Ad 03 17...