UV-USA_CAN SCC_WE, CM_P V06, 11/2016

11

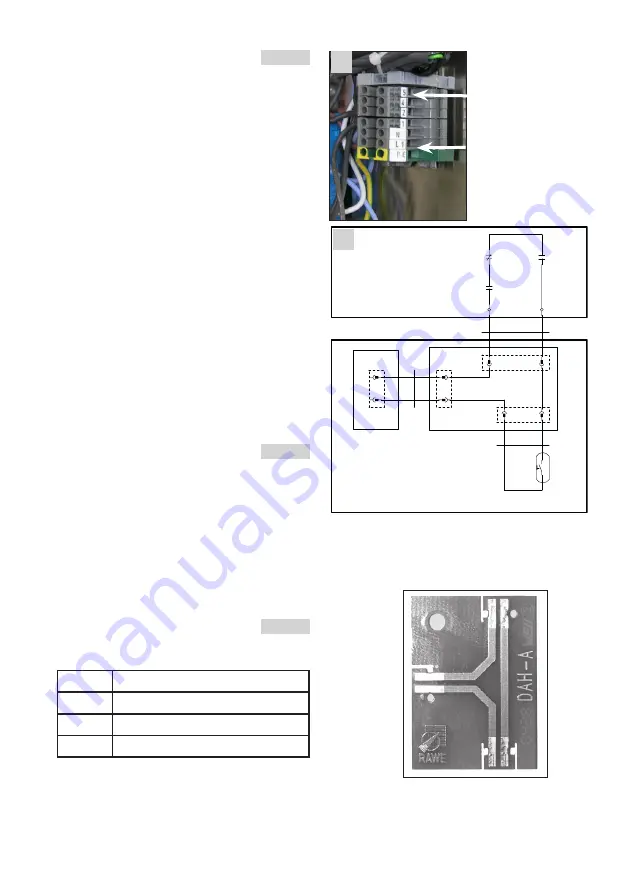

2.3 Power supply of the hood

pic. 14

- The Ultravent must electrically be connected in

accordance with the local regulations.

Before removing the plug or reconnecting to the

power supply, ensure that the operating switch is

in the "off” position.

- The Ultravent is delivered with power cord. The

terminals for power connection can be found in

the power box at the rear side of the Ultravent.

The color code of the terminals are:

PE = earth yellow/green (ground)

L = phase grey

N = neutral blue

- Also on the rear side of the hood there is an earth

connection stud. Fit the hood with a suitable cable

to the earth bonding (ground) system

2.4 The combination of Rational Combi and Ultra-

vent is electrically interlocked. The Combi shall

only operate under the following conditions:

a) The UV must be electrically switched "ON”

b) All filters (charcoal filter and fat filter) must be

correctly installed. This is controlled by ad-

ditional reed switches.

c) Charcoal filters must be clean

To connect this circuit proceed as follows:

pic 15

1. There is an extra interface pcb (A8) delivered with

the Ultravent kit. Fix it to the electrical mounting

plate of the combi at a suitable position.

2. In the kit also cable W24 (pic 1 item 9) is sup-

plied. Connect this cable to X23.1 of the interface

pcb (A8).

3. Run this cable W24 out of the electric compart-

ment through the cable gland back up to the

power box of the Ultravent. Connect brown wire

to terminal 4 and black wire to terminal 5 of the

power box.

pic 14

4. Remove 2 pole connector (door contact switch)

from pcb:

X27 - A1 I/O-pcb SCC Index E & G

X27 - A4 main pcb CM and CMP, Index E to H

X27 - A2 cpu-pcb SCC_WE, Index H

X4 - A7

pcb power supply lighting SCC, Index I

5. Connect the door contact switch to terminal X27.2

of the interface board A8.

14

X27.2

1

2

X23.1

1

2

X27.1

1

2

X4 / X27

11

22

A1 - A7

Connections:

refer to step 6

4

5

W23

Rel3

Error relay

Rel2

Filter relay

Ultravent

Combi steamer

W24

S3

Door contact switch

W25

A8

Interface pcb

Rel1

“On” relay

terminal 4 and 5 to

X23.1of A8

15

X23.1

X27.2

X27.1

A8

Mains input

PE = earth yellow/green

L = phase grey

N = neutral blue