INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 57 of 64

2 1

2 1

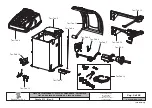

SCREW CHUCK

PNEUMATIC MANDREL

GAR306

1

2

1

2

Fig. 120A

SCREW CHUCK

PNEUMATIC MANDREL

GAR304

1

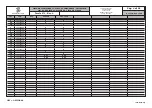

KEY

1 – Exit from the width measurement calibration

procedure and return to calibration menu page

(RED) (F1)

2 – Confirm storing of width measuring device posi-

tion on "end of shaft" (CENTRAL)

2

Fig. 120B

Press “CENTRE” to confirm the measurement. The

program will display the following page:

1

KEY

1 – Exit from the width measurement calibration

procedure and return to calibration menu page

(RED) (F1)

2 – Stores width measuring device position on "ex-

ternal flange surface” (CENTRAL)

2

Fig. 121

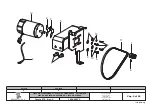

Move the tip of the width measuring device (

Fig. 122A

ref. 1

) in line with the outer surface of the flange

(

Fig. 122A ref. 2

) and press “F4”. The program will

show the screen page in

Fig. 122B

.

1297-M010-0_R

G2.124R - GP2.124R

RAVAGLIOLI S.p.A.