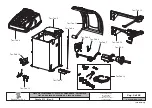

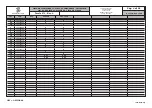

LISTA DEI COMPONENTI - LIST OF COMPONENTS - TEILELISTE

LISTE DES PIECES DETACHEES - LISTA DE PIEZAS

Pag. 13 di 22

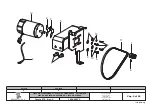

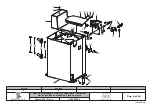

GRUPPO AZIONAMENTO FRENO

BRAKE OPERATION GROUP

SATZ FÜR BREMSBETÄTIGUNG

GROUPE ACTIONNEMENT FREIN

GRUPO ACCIONAMIENTO FRENO

Tavola N°8 - Rev. 0

129690152

1

2

RAVAGLIOLI S.p.A.

1297-R010-0_R

G2.124R

GP2.124R