INSTRUCTION, USE AND

MAINTENANCE MANUAL

EN

Page 39 of 91

11.0 AIR CONNECTION

On models with pneumatic chuck

EACH PNEUMATIC INTERVENTION

MUST BE CARRIED OUT BY PRO-

FESSIONALLY QUALIFIED STAFF.

IN CASE OF A CHANCE SUP-

PLY FAILURE, AND/OR BEFORE

ANY PNEUMATIC CONNECTIONS,

MOVE THE CONTROLS TO THE

NEUTRAL POSITION.

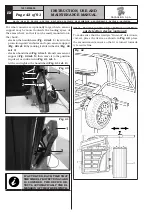

Connect the wheel balancer to the centralised com-

pressed-air system by means of the connection on the

back of the machine (see

Fig. 28

).

The air system supplying the machine must be able

to supply filtered and de-humidified air at a pressure

between 8 and 10 bar. It must feature an on-off valve

upstream of the machine.

Fig. 28

12.0 FITTING THE WHEEL ON THE

CHUCK

To achieve perfect balancing, the wheel must be care-

fully and properly fitted on the chuck. Imperfect cen-

tring will inevitably cause unbalances.

WHAT IS MOST IMPORTANT IS

THAT ORIGINAL CONES AND

ACCESSORIES, SPECIALLY DE-

SIGNED TO BE EMPLOYED WITH

THE WHEEL BALANCERS, ARE

USED.

Wheel fitting using the cones provided is illustrated be-

low. For alternative fittings, using optional accessories,

refer to the special instructions provided separately.

12.1 Wheel assembly

For models with threaded chuck

1. Remove any type of foreign body from the wheel

(

Fig. 29 ref. 3

): pre-existing weights, stones and

mud, and make sure the chuck (

Fig. 29 ref. 1

)

and the rim centring area are clean before fitting

the wheel on the chuck.

2. Carefully choose the cone (

Fig. 29 ref. 2

) most suit-

able for the wheel to be balanced. These accessories

must be selected according to the shape of the rim.

Position the wheel (

Fig. 29 ref. 3

), fitting the cone

(

Fig. 29 ref. 2

) on the chuck (

Fig. 29 ref. 1

): be

careful (otherwise this could seize) until this rests

against the support flange (

Fig. 29 ref. 4

).

3. Fit the wheel with the inner side of the rim towards

the wheel balancer and against the cone.

Fig. 29

1297-M058-00

G3.150 - GP3.150 - G3.150S - GP3.150S - G3.150WS - GP3.150WS - G3.150WSPLUS - GP3.150WSPLUS - G3.150SA - G3.150WSA

RAVAGLIOLI S.p.A.