Instruction manual

RAVAGLIOLI S.p.A.

RAVTD1760 WS – RAVTD1780 WS

Code M0197 - rev.1.0

(11/2010)

RAVAGLIOLI S.p.A. -

Via I° Maggio, n° 3 (Pontecchio Marconi)

Page 7/52

40037 Sasso Marconi (Bologna - Italy)

Tel. 051/ 67.81.511 – Fax 051/ 84.64.67 E-mail: rav@ravaglioli.com

3.6 Detectors

Detectors assembled on RAVTD1760WS and RAVTD1780WS do not need any cable or cord

connection for angle measurement.

Detecting units consist of infrared data transmitters/receivers and CCD-type transducers

with infrared emitter focal point.

All the characteristic angles of vehicle axles are controlled with 8 CCD sensors and infrared

transmission.

Data transmission among infrared detectors is effective also under critical lighting

conditions.

Data are transmitted from front detectors VIA RADIO through modules

located inside front detectors and cabin.

Rear detectors do not communicate directly with cabin: their data are transmitted/received

through front detectors, via infrared ray transmission.

Power is supplied by rechargeable 6V long-lasting batteries. Front and rear detectors are

recharged thanks to the supports for batteries recharge positioned onto cabin.

For all detectors with rechargeable batteries, power supply and consumption data are the

following:

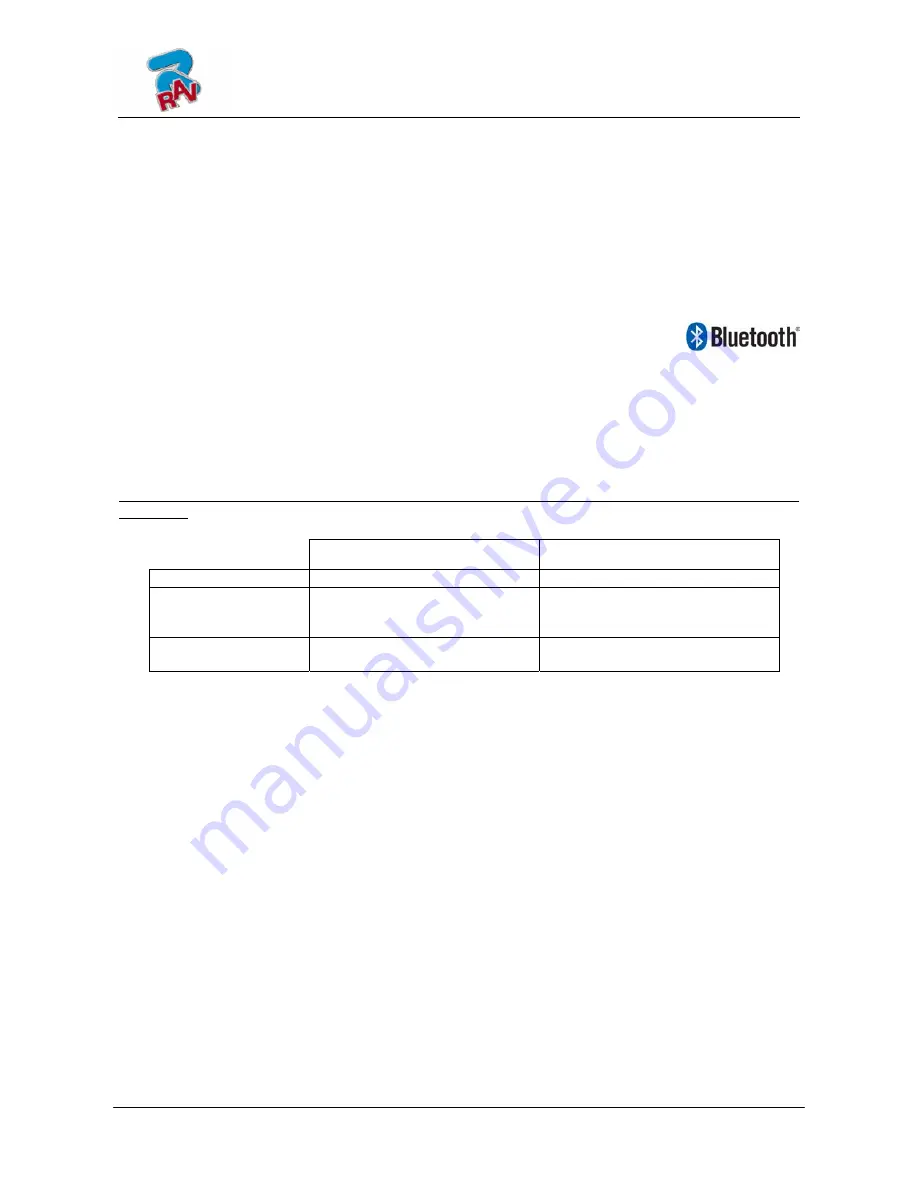

REAR DETECTORS

FRONT DETECTORS

Power supply

Lead battery 6V - 3.3Ah

Lead battery 6V - 3.3Ah h

Average operation

with fully effective

and charged battery

Approx. 12 hours

Approx. 10 hours

Average recharge

time

Approx. 10 hours

Approx. 10 hours