80

ENGLISH

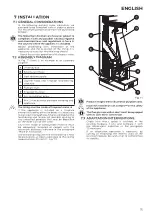

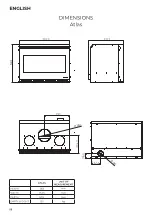

9.3 OPERATION

9.3.1 Combustion control

Combustion is adjusted using the air regulator

(A) (Fig. 9.2). Turning it toward the symbols (+) or

(-) a higher or lower flow of combustion air will

be obtained and consequently a faster or slower

combustion will result.

9.3.2 Glass cleaning

During operation, it is possible to facilitate the

cleaning of the ceramic glass by means of the

adjustment lever (A) (Fig. 9.2) without having to

open the door.

If the lever is opened completely (+) a flow of

air hits the ceramic glass surface, cleaning it. To

carry out this operation.

Product images are for illustrative purposes only.

A

Fig. 9.2

10 CLEANING AND

MAINTENANCE

Cleaning can be carried out by the user.

Maintenance operations must be performed by

an authorised technical assistance centre.

Before carrying out any cleaning and/or

maintenance operations, take the following

precautions:

• Ensure that all appliance parts are cold.

• Make sure that the ashes are completely

extinguished.

• Use personal protective equipment provided

for by Directive 89/391/EEC.

• Ensure that the main power switch is switched

off (if present).

• Make sure that the power supply cannot be

accidentally reactivated. Disconnect the plug

from the wall socket (if present).

• Always use appropriate equipment for

maintenance.

• Once maintenance or repair operations have

been completed, before putting the appliance

back into service, reinstall all the safety guards

and reactivate all the safety devices.

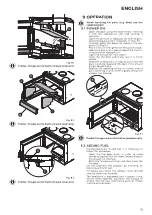

10.1 ROUTINE MAINTENANCE

CLEANING PROGRAM

10.1.1 Routine cleaning (User)

EVERY

TIME THE

APPLI-

ANCE IS

TURNED

ON

EVERY

WEEK

1 MONTH

Grate

(Fig. 10.1)

X

Ash drawer

/ compart-

ment

(Fig. 10.2)

X

Glass

(Fig. 10.3)

X

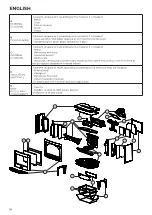

10.1.2 Routine maintenance (certified

technical service centre)

1 YEAR*

Gaskets (door, refractory cements,

etc...)

X

Flue manifold

X

Door safety

X

Flue system (refer to section

“Maintenance of the smoke

system”)

X

Appliance (refer to section

“Appliance maintenance”)

X

*

At least once a year or every 4000 kg of fuel

burned.