82

ENGLISH

10.3 ROUTINE MAINTENANCE

10.3.1 Maintenance of flue manifold

Open the door and remove, in this order, the back

wall (A), the side walls (B) and the upper deflector

(C) (paragraph “Adjusting the bypass valve”).

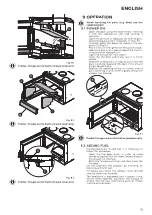

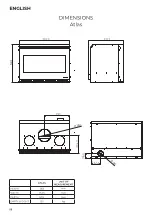

Remove the flue manifold cap (A) (Fig. 10.4).

Product images are for illustrative purposes only.

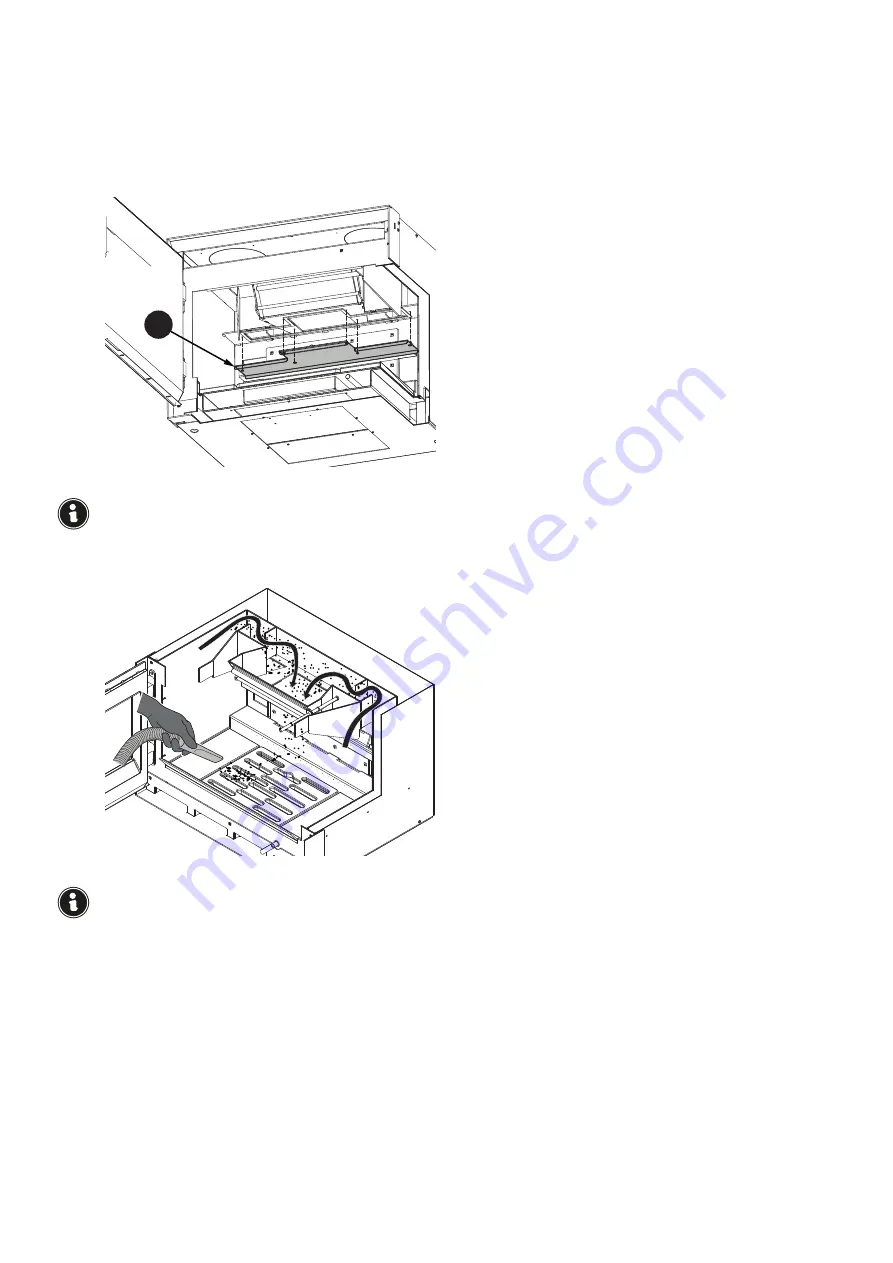

Use a flexible brush to clean the pipes in the

combustion chamber (Fig. 10.5).

Remove any residues that fall in the flue manifold

using an ash vacuum.

Product images are for illustrative purposes only.

10.3.2 Maintenance of the smoke system

To be carried out at least once a year, or every 4000

kg of fuel burned (as specified in the product

standard), by contacting specialist personnel

If there are horizontal sections, it is necessary to

check and remove any deposits of ash and soot

before they obstruct the passage of fumes.

The incrustations inside the flue affect the

optimum forced draught. When they reach a

thickness of 5-6 mm, with high temperatures

and sparks, they can ignite with easily imaginable

consequences both for the flue and for the house.

A

Fig. 10.4

Fig. 10.5

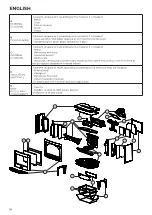

10.3.3 Appliance maintenance

To be carried out at least once a year, or every

time the appliance signals maintenance request.

During the maintenance operation, the

technician must:

• clean the flue gas transit area thoroughly and

completely;

• check the adjustment of the bypass valve;

• check the condition and tightness of all the

seals;

• check the condition of all internal components

and make sure they are clean;

• make sure the flue gas outlet connection is

sealed and clean;

• check the correct operation of the appliance.