8

6

7

2.6

Flammable Liquids

2.7

Operating Instructions

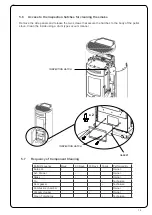

the switching off phase, guaranteeing safe functioning. The burn pot used for combustion allows most

The stove is completely automated and will self-regulate the ignition phase,

of the ashes produced by the combustion of the pellets to fall into the collection drawer. However,

it is recommended that you check the burn pot every day, as not all pellets have high standards of

a diameter of 6mm, manufactured to the AS/NZ4014.6 or higher must be used with the stove.

2.8

Safety Devices

is installed. In any case, when a problem arises, the pellets stop falling immediately and the switch off

phase is activated. The corresponding alarm will be shown on the display. The details can be seen in

the chapter on the alarms (see page 28).

2.9 Responsibility

Pellet

e

r

i

F

s

n

o

it

u

l

o

S

declines all responsibility, both civil and criminal, with the delivery of this

manual, for any accidents deriving from partial or total failure, to observe the instructions it contains.

Pellet

e

r

i

F

s

n

o

it

u

l

o

S

declines all responsibility deriving from the improper use of the stove, from its

which are not original. The manufacturer declines all direct, civil or criminal responsibility due to:

•

Poor maintenance.

•

Failure to observe the instructions in the manual.

•

Use not compliant with the safety instructions.

•

Installation that is not compliant with the regulations in force in the country.

•

•

manufacturer.

•

Use of spare parts that are not original.

•

Exceptional events.

2.10 Spare Parts

.

m

e

h

t

g

n

i

c

a

l

p

e

r

e

r

o

f

e

b

n

r

o

w

e

b

o

t

s

t

n

e

n

o

p

m

o

c

e

h

t

r

o

f

ti

a

w

t

o

n

o

D

.

y

l

n

o

s

t

r

a

p

e

r

a

p

s

l

a

n

i

g

i

r

o

e

s

U

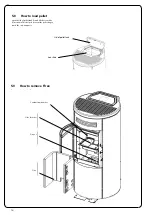

Replace a worn component before it is completely broken, to prevent any accidents caused by the

sudden breakage of components. Perform the periodic maintenance checks as described in the

dedicated chapter on “Maintenance and Cleaning” on page 9.

Installation by personnel who are not qualified or authorised.

Never use gasoline, gasoline – type lantern fuel, kerosene, charcoal lighter fluid or similar liquids to

start or “freshen” up a fire in the stove. Keep all such liquids well away from the stove while it is use.

The stove is fitted with a sophisticated safety systems so that, in the case of breakage of one of the

individual parts, or defects in the flue, no damage will be caused to the stove and the room in which it

quality, and could leave residue that is difficult to remove. The glass has special air circulation for self-

incorrect use by the user, by unauthorised modifications and/or repairs, or from the use of spare parts

five levels of power and