Manuale uso e manutenzione S70- S90- SC90

Pag.42

Rev.0 18/05/2020

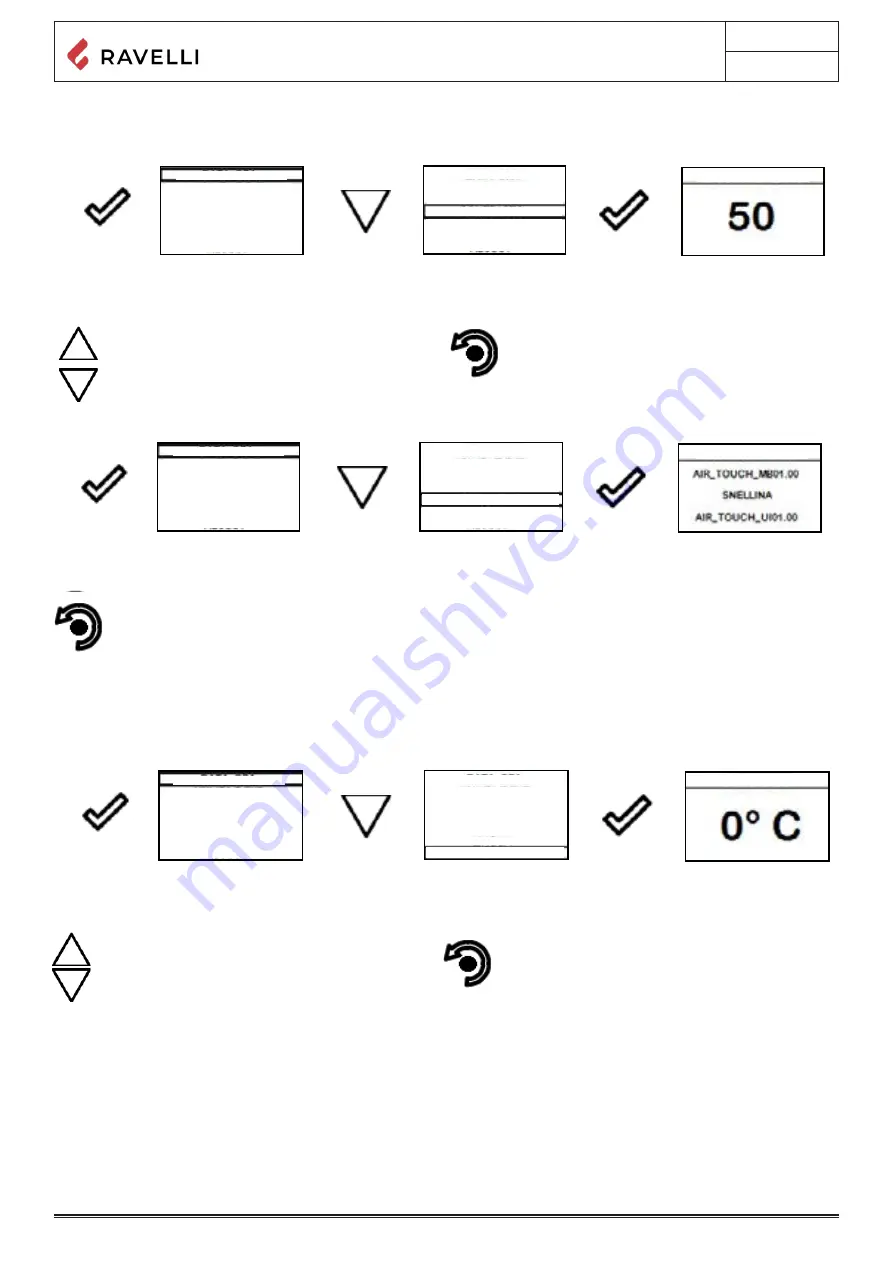

Settings > Contrast

With this function you can change the contrast setting to improve the display of your handheld. The contrast setting to improve the

display of the handheld display.

Use the UP/DOWN keys to change contrast setting and

obtain a better visualisation of the information shown

on the handheld set.

The value can vary from 0 to 100. 50 with respect to

the standard value.

By pressing the following key you will confirm of data

and switch to the page within SETTINGS menu.

Manuale utente PALMARE IDRO TOUCH RADIO

Manuale utente PALMARE IDRO TOUCH RADIO

Pag.30

Pag.31

Vers. 01 del 07/04/15

Vers. 01 del 07/04/15

Below are given the steps for accessing the relative menu starting from Stand-By mode.

Stove State

Press the key

“access menu” to

access the

MENU page

Press the key

“confirm”

to access the

USER page

Press the key

several times

to quickly switch to

Stove STATUS.

To exit the STOVE STATE page and return to Stand-by page, press the button repeatedly.

In this mode you can check the proper operation of the most important parameters of the appliance. Here is a list of real data of the

stove useful for service during inspection.

- Circulator state (ON running)

- Position of 3-way valve DHW (domestic hot water) or HEAT (heating);

- System pressure;

- Stove state;

- Current boiler power;

- Flow read by the flow meter;

- Fume extractor speed;

- Actual flow set;

Settings > Enable thermostat

Press the “enter” key

to access the

SETTINGS

Press the key

“selection” to switch to

ENABLE THERMOSTAT.

Press the key

“confirm”

to access the function

Press the key

“confirm”

to enable the function.

In Stand-By mode, instead of room temperature measured

and settable, appears the line T ON if the room in which

the thermostat is installed has not reached the temperature

requested or the writing T OFF if the temperature in the

room is reached.

Press the key for several

times

to return to

“STAND BY” page

- Temperature read by the handheld unit;

- External thermostat (request ON);

- Flame temperature (combustion chamber);

- Combustion fume exhaust temperature;

- Inlet flow meter temperature;

- Heated flow meter temp.;

- Electronic board temperature;

- Boiler water temperature (SUPPLY);

- Boiler water temperature (optional) - RETURN from the system;

- Boiler DHW temperature;

- Puffer temperature - average warm point;

- Puffer temperature second reading (low temp.).

Below are given the steps for accessing the relative menu starting from Stand-By mode.

Settings

Press the key

“access menu” to

access the

MENU page

Press the key

“confirm”

to access the

USER page

Press the key

“selection” to switch to

second menu page

to the function

SETTINGS.

After following the procedure above step by step, you can set the following functions:

Settings > Contrast

Press the key

“confirm” to

access the

SETUP

SETTINGS

Press the key

“selection” to switch

to the function

CONTRAST.

Press the key

“confirm”

to access the function

Use the UP/DOWN keys to change contrast setting and obtain

a better visualisation of the information shown on the handheld

set.

The value can vary from 0 to 100. 50 with respect to the

standard value.

By pressing the following key you will confirm of data

and switch to the page within SETTINGS menu.

Settings > Season

Press the key

“confirm” to

access the

SETUP

SETTINGS

Press the key

“selection” to switch

to the function

CONTRAST.

Press the key

“confirm”

to access the function

Use the UP/DOWN keys to change the WINTER/

SUMMER season. Function that can be set when

working with DHW puffer (Boiler).

See chap. Evolved hydraulic diagrams

By pressing the following key you will confirm of data

and switch to the page within SETTINGS menu.

Press the “enter” key to

access the

SETTINGS

Press the key

“selection” to switch to

CONTRAST.

Press the key

“confirm”

to access the function

Settings > Firmware version

By pressing the button you will confirm the data and switch to the page within the SETTINGS menu.

MENU

STOVE STATE

STOVE STATE

STOVE STATE

STOVE STATE

USER

ACTIVE PARTS

ACTIVE PARTS

ACTIVE PARTS

ACTIVE PARTS

ACTUAL STATES

PUMP

PRESSURE 1.1 BAR

SHUTDOWN

POWER MOD

HH T …

EXT.T …

FLAME T 340°C

FUME T 120°C

F. EX. T 30°C

C. EX. T 55°C

EL B. T---25°C

T. CALDERA

T.PUFFER H

T.PUFFER L

3-WAY VALVE HEAT

ACTUAL STATES

ACTUAL STATES

ACTUAL STATES

H20 TEMPERATURE

H20 TEMPERATURE

v

H20 TEMPERATURE

TECHNICIAN

STATE TEMPERATURE

STATE TEMPERATURE

STATE TEMPERATURE

STATE TEMPERATURE

USER

USER

POWER SETTING

STOVE STATE

CHRONOTHERMOSTAT

COMFROT CLIMA

SCREW LOADING

SETTING

SET AIR-PELLET

DATE-TIME

DATE-TIME

DATE-TIME

DATE-TIME

DATE-TIME

WINTER

CONTRAST

FIRMWARE

SUMMER

DATE-TIME

ENABLE THERMOSTAT

ENABLE THERMOSTAT

ENABLE EXT. T

ENABLE EXT. T

ENABLE EXT. T

ENABLE EXT. T

ENABLE EXT. T

ENABLE EXT. T

SEASON

SEASON

SEASON

SEASON

SEASON

SEASON

CONTRAST

CONTRAST

CONTRAST

CONTRAST

CONTRAST

CONTRAST

FW VERSION

FW VERSION

FW VERSION

FW VERSION

FW VERSION

FW VERSION

LANGUAGE

LANGUAGE

LANGUAGE

LANGUAGE

LANGUAGE

LANGUAGE

ADJUST

ADJUST

ADJUST

ADJUST

ADJUST

ADJUST

DATE-TIME

ENABLE EXT. T

SEASON

CONTRAST

FW VERSION

LANGUAGE

ADJUST

DATE-TIME

ENABLE EXT. T

SEASON

CONTRAST

FW VERSION

LANGUAGE

ADJUST

MENU

USER

TECHNICIAN

USER

USER

POWER SETTING

STOVE STATE

CHRONOTHERMOSTAT

COMFROT CLIMA

SCREW LOADING

SETTING

SET AIR-PELLET

MANUFACTURER’S

MANUFACTURER’S

Settings > Adjust

The adjust function allows to modify the value read by the room probe inside the handheld computer, increasing or decreasing it by

the set value (offset).

Make this adjustment carefully and only after having checked deviations from the actual room temperature with a reliable instrument!

Manuale utente PALMARE IDRO TOUCH RADIO

Manuale utente PALMARE IDRO TOUCH RADIO

Pag.32

Pag.33

Vers. 01 del 07/04/15

Vers. 01 del 07/04/15

Press the key

“confirm” to

access the

SETUP

SETTINGS

Press the key

“selection” to switch

to the function

VERSION FW.

Press the key

“confirm”

to access the function

To access the next setting, follow the steps given above or simply remove and replace the batteries.

The device resets and prompts you again to select the language you want to set.

Settings > Language

Settings > Adjust

Use the UP/DOWN keys to change the value read by the

room temperature probe installed inside the handheld

set, with respect to a reference value.

The value can vary from -10°C to 10°C.

The standard value is 0°C.

By pressing the following key you will confirm of data

and switch to the page within SETTINGS menu

The stoves equipped with ventilation system can heat the area in which are installed through the heat generated by the window and

the room temperature fan installed inside them.

Below are the messages shown on display when the stove is equipped with ventilation system.

To exit the page and return to Stand-by page, press the button repeatedly.

VENTILATION menu (function only for models in which the same is specified in the dedicate user’s manual)

Control: v

entilation can be set from 0 to AUTO where 0 indicates that the same is disabled, setting from MIN to MAX enables selecting

the heat distribution speed. If set to AUTO, the ventilation follows the power set on the stove.

Press the increase/decrease keys

“increase/decrease”

to change the ventilation.

To exit the page and return to Stand-by page, press the button repeatedly.

The exit key shows the CHRONO menu to set other variables related to the menu functions.

Press the key

“enter” at the end of the

setting, from the following

CHRONO page

The temperature read by the handheld unit controls the modulation of the stove. If you want to adjust the ventilation by

adjusting the stove, set the fan to A mode as shown in the relative chapter.

Press the key

“access menu” to

access the

MENU page

Press the key

“confirm”

to access the

USER page

Press the key

“confirm”

to quickly switch to

VENTILATION.

Press the increase/decrease keys

“increase/decrease”

to change the ventilation.

Pages displayed upon the activation of advanced layouts

By activating a layout different from the standard (layout 0), even if maintaining the same functions of the menu, the “Stand-by” page will

display all connected utilities such as the temperature of the boiler of the puffer.

Below is shown the new display mode and the function of every icon for every layout, to change the various settings.

Layout 1 (DHW heating control)

The following layout can be used when you have a boiler that is not equipped with plate heat exchanger and you intend to buy a puffer

that should be connected to the circuit to produce hot domestic water.

In this type of circuit, room temperature is controlled however by the handheld unit which, being a radio device, acts as a remote

chronothermostat. The boiler is managed by the thermostove through a contact or immersion probe (not supplied) connected directly

to the back of the stove. Below is shown the new “Stand-by” mode.

By setting the SUMMER function, the 3-way valve remains fixed in a single position, enabling the release of heat output

by the stove exclusively inside the boiler. As soon as this condition is reached, the boiler switches to ECO STOP mode.

The operation is the same as for the basic layout except for the fact that in this layout, the boiler exchanges heat directly in the

boiler (priority); when the temperature set is reached, the 3-way valve changes its position and the boiler starts exchanging heat within

the heating circuit. From this moment, the stove is controlled by the radio handheld unit for contolling the room

temperature or via H2 setting (see the operation with layout 0 to find the data on modulation, eco stop etc.).

The 3-way valve is directed again into the boiler when:

- there is a request from the Boiler;

- there is a requested from the flow switch (optional, if connected).

The stove restarts from Eco-stop or Stand by mode according to heating requests or boiler requests.

T°C Boiler

From STAND BY mode, press

the ARROW key UP

to set the

room T°C

and DHW boiler T°C that you

desire.

Boiler water T°C

From STAND BY mode, press

the ARROW key DOWN

to set

the boiler water T°C

that you desire.

Press the key

“V” from STAND BY page

to display the actuale states and

the room temperature

Chrono function

By enabling the chrono function, it is possible to control the ventilation speed for each program as shown in the logic above.

Press the key

“access menu” to

access the

MENU page

Press the key

“confirm”

to access the

USER page

Press the key

several times

to quickly switch to

CRONO-THERMOSTAT.

If the type of system designed requires controlling the 3-way valve (diagram 1 and 3), it is necessary to purchase the

optional kit from the retailer or the authorized Ravelli dealer.

DATE-TIME

DATE-TIME

ENABLE EXT. T

ENABLE EXT. T

SEASON

SEASON

CONTRAST

CONTRAST

FW VERSION

FW VERSION

LANGUAGE

LANGUAGE

ADJUST

ADJUST

ADJUST

MENU

USER

TECHNICIAN

VENTILATION POW.

USER

POWER SETTING

CHRONOTHERMOSTAT

SCREW LOADING

SET AIR-PELLET

MENU

USER

TECHNICIAN

USER

USER

POWER SETTING

POWER SETTING

SET AIR-PELLET

SET AIR-PELLET

CHRONOTHERMOSTAT

CHRONOTHERMOSTAT

SCREW LOADING

SCREW LOADING

CHRONO

CHRONO

ENABLE CHRONO

ENABLE CHRONO

ENABLE CHRONO

ENABLE CHRONO

VENTILATION POW.

SET CHRONO 1

SET CHRONO 1

SET CHRONO 2

SET CHRONO 2

SET CHRONO 3

SET CHRONO 3

SET CHRONO 4

SET CHRONO 4

POWER MOD

PUMP

3-WAY VALVE HEAT

PRESSURE 1.1 BAR

HH T .

21°C

MANUFACTURER’S

MANUFACTURER’S

UP” and “DOWN” buttons The value can vary from

-10°C to 10°C. The standard value is 0°C.

Pressing the following key allows you to confirm the

data and move to the screen within the SETTINGS

menu.

Settings > Language

To access the next setting, follow the steps given above or simply remove and replace the batteries.

The device resets and prompts you again to select the language you want to set.

Settings > Firmware version

By pressing the button you will confirm the data and switch to the page within the SETTINGS menu.

Manuale utente PALMARE IDRO TOUCH RADIO

Manuale utente PALMARE IDRO TOUCH RADIO

Pag.30

Pag.31

Vers. 01 del 07/04/15

Vers. 01 del 07/04/15

Below are given the steps for accessing the relative menu starting from Stand-By mode.

Stove State

Press the key

“access menu” to

access the

MENU page

Press the key

“confirm”

to access the

USER page

Press the key

several times

to quickly switch to

Stove STATUS.

To exit the STOVE STATE page and return to Stand-by page, press the button repeatedly.

In this mode you can check the proper operation of the most important parameters of the appliance. Here is a list of real data of the

stove useful for service during inspection.

- Circulator state (ON running)

- Position of 3-way valve DHW (domestic hot water) or HEAT (heating);

- System pressure;

- Stove state;

- Current boiler power;

- Flow read by the flow meter;

- Fume extractor speed;

- Actual flow set;

Settings > Enable thermostat

Press the “enter” key

to access the

SETTINGS

Press the key

“selection” to switch to

ENABLE THERMOSTAT.

Press the key

“confirm”

to access the function

Press the key

“confirm”

to enable the function.

In Stand-By mode, instead of room temperature measured

and settable, appears the line T ON if the room in which

the thermostat is installed has not reached the temperature

requested or the writing T OFF if the temperature in the

room is reached.

Press the key for several

times

to return to

“STAND BY” page

- Temperature read by the handheld unit;

- External thermostat (request ON);

- Flame temperature (combustion chamber);

- Combustion fume exhaust temperature;

- Inlet flow meter temperature;

- Heated flow meter temp.;

- Electronic board temperature;

- Boiler water temperature (SUPPLY);

- Boiler water temperature (optional) - RETURN from the system;

- Boiler DHW temperature;

- Puffer temperature - average warm point;

- Puffer temperature second reading (low temp.).

Below are given the steps for accessing the relative menu starting from Stand-By mode.

Settings

Press the key

“access menu” to

access the

MENU page

Press the key

“confirm”

to access the

USER page

Press the key

“selection” to switch to

second menu page

to the function

SETTINGS.

After following the procedure above step by step, you can set the following functions:

Settings > Contrast

Press the key

“confirm” to

access the

SETUP

SETTINGS

Press the key

“selection” to switch

to the function

CONTRAST.

Press the key

“confirm”

to access the function

Use the UP/DOWN keys to change contrast setting and obtain

a better visualisation of the information shown on the handheld

set.

The value can vary from 0 to 100. 50 with respect to the

standard value.

By pressing the following key you will confirm of data

and switch to the page within SETTINGS menu.

Settings > Season

Press the key

“confirm” to

access the

SETUP

SETTINGS

Press the key

“selection” to switch

to the function

CONTRAST.

Press the key

“confirm”

to access the function

Use the UP/DOWN keys to change the WINTER/

SUMMER season. Function that can be set when

working with DHW puffer (Boiler).

See chap. Evolved hydraulic diagrams

By pressing the following key you will confirm of data

and switch to the page within SETTINGS menu.

Press the “enter” key to

access the

SETTINGS

Press the key

“selection” to switch to

CONTRAST.

Press the key

“confirm”

to access the function

Settings > Firmware version

By pressing the button you will confirm the data and switch to the page within the SETTINGS menu.

MENU

STOVE STATE

STOVE STATE

STOVE STATE

STOVE STATE

USER

ACTIVE PARTS

ACTIVE PARTS

ACTIVE PARTS

ACTIVE PARTS

ACTUAL STATES

PUMP

PRESSURE 1.1 BAR

SHUTDOWN

POWER MOD

HH T …

EXT.T …

FLAME T 340°C

FUME T 120°C

F. EX. T 30°C

C. EX. T 55°C

EL B. T---25°C

T. CALDERA

T.PUFFER H

T.PUFFER L

3-WAY VALVE HEAT

ACTUAL STATES

ACTUAL STATES

ACTUAL STATES

H20 TEMPERATURE

H20 TEMPERATURE

v

H20 TEMPERATURE

TECHNICIAN

STATE TEMPERATURE

STATE TEMPERATURE

STATE TEMPERATURE

STATE TEMPERATURE

USER

USER

POWER SETTING

STOVE STATE

CHRONOTHERMOSTAT

COMFROT CLIMA

SCREW LOADING

SETTING

SET AIR-PELLET

DATE-TIME

DATE-TIME

DATE-TIME

DATE-TIME

DATE-TIME

WINTER

CONTRAST

FIRMWARE

SUMMER

DATE-TIME

ENABLE THERMOSTAT

ENABLE THERMOSTAT

ENABLE EXT. T

ENABLE EXT. T

ENABLE EXT. T

ENABLE EXT. T

ENABLE EXT. T

ENABLE EXT. T

SEASON

SEASON

SEASON

SEASON

SEASON

SEASON

CONTRAST

CONTRAST

CONTRAST

CONTRAST

CONTRAST

CONTRAST

FW VERSION

FW VERSION

FW VERSION

FW VERSION

FW VERSION

FW VERSION

LANGUAGE

LANGUAGE

LANGUAGE

LANGUAGE

LANGUAGE

LANGUAGE

ADJUST

ADJUST

ADJUST

ADJUST

ADJUST

ADJUST

DATE-TIME

ENABLE EXT. T

SEASON

CONTRAST

FW VERSION

LANGUAGE

ADJUST

DATE-TIME

ENABLE EXT. T

SEASON

CONTRAST

FW VERSION

LANGUAGE

ADJUST

MENU

USER

TECHNICIAN

USER

USER

POWER SETTING

STOVE STATE

CHRONOTHERMOSTAT

COMFROT CLIMA

SCREW LOADING

SETTING

SET AIR-PELLET

MANUFACTURER’S

MANUFACTURER’S

Summary of Contents for Flexi 7

Page 1: ...USE AND MAINTENANCE MANUAL Flexi 7 Flexi 9...

Page 2: ......