User and maintenance manual for stoves with RDS technology

Pag.8

01/02/2016

3.3. Majolica finishes

Due to the special hand finish of the majolica surface imperfections such as shadowing my accour .Those are details that make every

majolica one of its kind. As it is a delicate material, please handle with care whilst cleaning and avoid blows as sudden breakage may occur.

Please also take care when loading the hopper (Ed.’s note; tank containing the pellets) with the bag of pellets: do not place it on the

stove!

3.4. What are the wood pellets

The wood pellets are made from sawdust and wood shavings produced in joiners’ shops. The material used cannot contain any foreign

substance such as glue, varnish or synthetic substances.

Subjecting it to high pressure, the wood is pressed through a plate with holes and due to the high pressure the sawdust is heated activating

the natural binders of the wood. Thus, the pellets keep their shape even without the addition of bonding substances. The density of the wood

pellet varies according to the type of wood and can be 1.5 – twice greater than that of natural wood.

The diameter of the cylindrical rods is 6 mm and their length can vary between 10 and 40 mm.

Their real weight is greather than 650 kg/m

3

. Due to the low content of water (<10%) they have a high energy content.

The standards ISO 17225-2:2014 define the quality of the pellets:

Pic.2

The pellets must be transported and stored in a dry place. They swell on contact with damp, and cannot be used, They must always be

protected from the damp both during transport and in storage. Do not place such fuel within the space heater installation clearances or

within the space required for charging and ash removal.

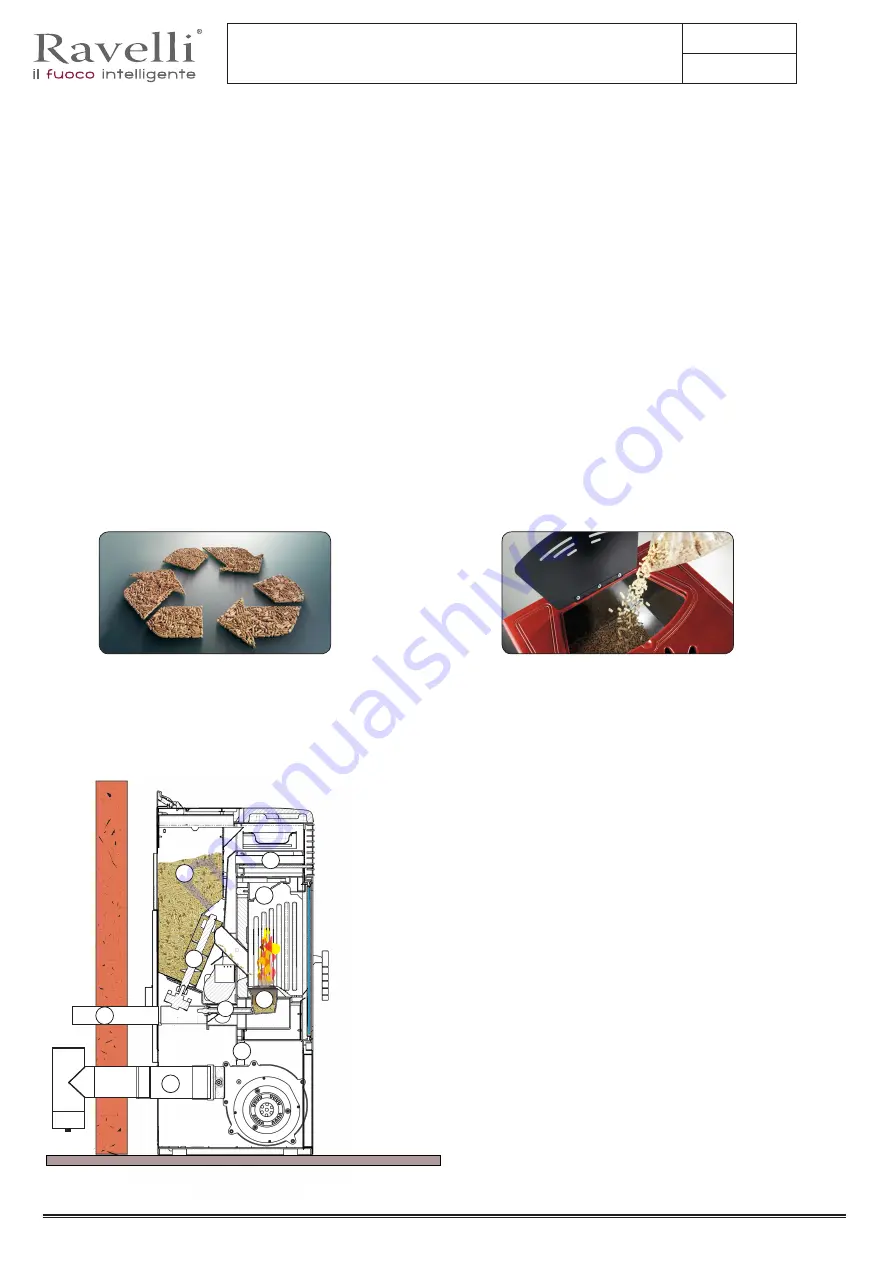

Pic.1

1. pellet loading screw

2. electrical igniter

3. combustion fire pot

4. tube for passage of smoke

5. air intake tube

6. stainless steel heat exchanger

7. pellet hopper

8. baffle

9. smoke exhaust tube

This drawing shows the internal parts of a pellet stove.

By filling the hopper (7), the pellets are loaded into the fire

pot (3) through the loading screw (1).

Ignition is by means of the electrical igniter (2), which

overheats the air from the special entrance (5) which on

contact with the pellets will allow the development of the

flame. At this point the exhaust smoke is deviated towards

the stainless steel exchanger (6) and through the smoke

extraction tube (4) it is released into the flue, through the

connection with the smoke exhaust pipe. (9).

7

2

3

6

1

8

9

5

4

9

3.5. The components of the stove

Length:

Diameter:

Real weight:

Lower heating value:

Residual humidity:

Ashes:

Specific weight:

< 40 mm

6 mm approx.

> 600 kg/m

3

≥ 16,5 MJ/kg (≥ 7100 BTU/lb)

< 10 %

< 1.2 %

>1000 kg/m

3

Do not put the bag of pellets on the

ceramic parts during the loading

operations.