17

Manuale utente PALMARE IDRO TOUCH RADIO

Manuale utente PALMARE IDRO TOUCH RADIO

Pag.26

Pag.27

Vers. 01 del 07/04/15

Vers. 01 del 07/04/15

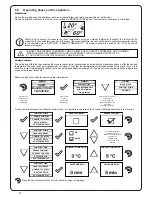

Operating phases of the appliance

During the work phases, the appliance is aimed at reaching the room/water temperature set by the user;

when one of these conditions is met, the stove switches to MODULE WORK phase, in which fuel consumption is minimised.

Modulation

Should it be necessary to measure the room temperature using an external thermostat (optional), the latter must be

connected to the dedicated connector to the rear of the stove; therefore, the user will be able to enable temperature reading

in the dedicated menu “SETTINGS - ENABLE THERMOSTAT”. On display appears the writing TON / TOFF based on

thermostat request.

CONNECT AN EXTERNAL THERMOSTAT WITH A SIMPLE DRY CONTACT, THEREFORE, NOT POWERED.

MOREOVER, WE RECOMMEND YOU USE A THERMOSTAT WITH A MINIMUM OFFSET OF 3°C

IF YOU INTEND TO USE THE COMFORT CLIMA FUNCTION.

The activation of this function enables the stove to reduce pellet consumption by activating the modulation phases, after the desired

temperature has been reached. Subsequently, the stove checks that the temperature is maintained steady for a preset time. If this

condition is met, it automatically switches off, and on display appears the writing ECO. The stove turns on again when the temperature

drops below the set threshold.

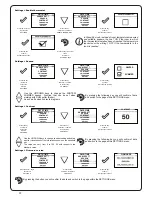

Below are given the steps for accessing the relative menu.

Comfort climate

Press the key

“access menu” to

access the

MENU page

Press the key

“confirm”

to access the

USER page

Press the key “selection” for

several times

to go to the second

page of the USER menu

and select

CLIMATE COMFORT.

Once you have accessed the Climate Comfort menu, it is possible to operate on the 4 types of settings dedicated to the function:

Press the key for several times until the Stand-by page is displayed.

Setting ambient and boiler water temperature:

Set the two values following the indications given in the chapter “Description of the display”

Turning the device on

Keep the key ON/OFF pressed for a few seconds to turn on the stove.

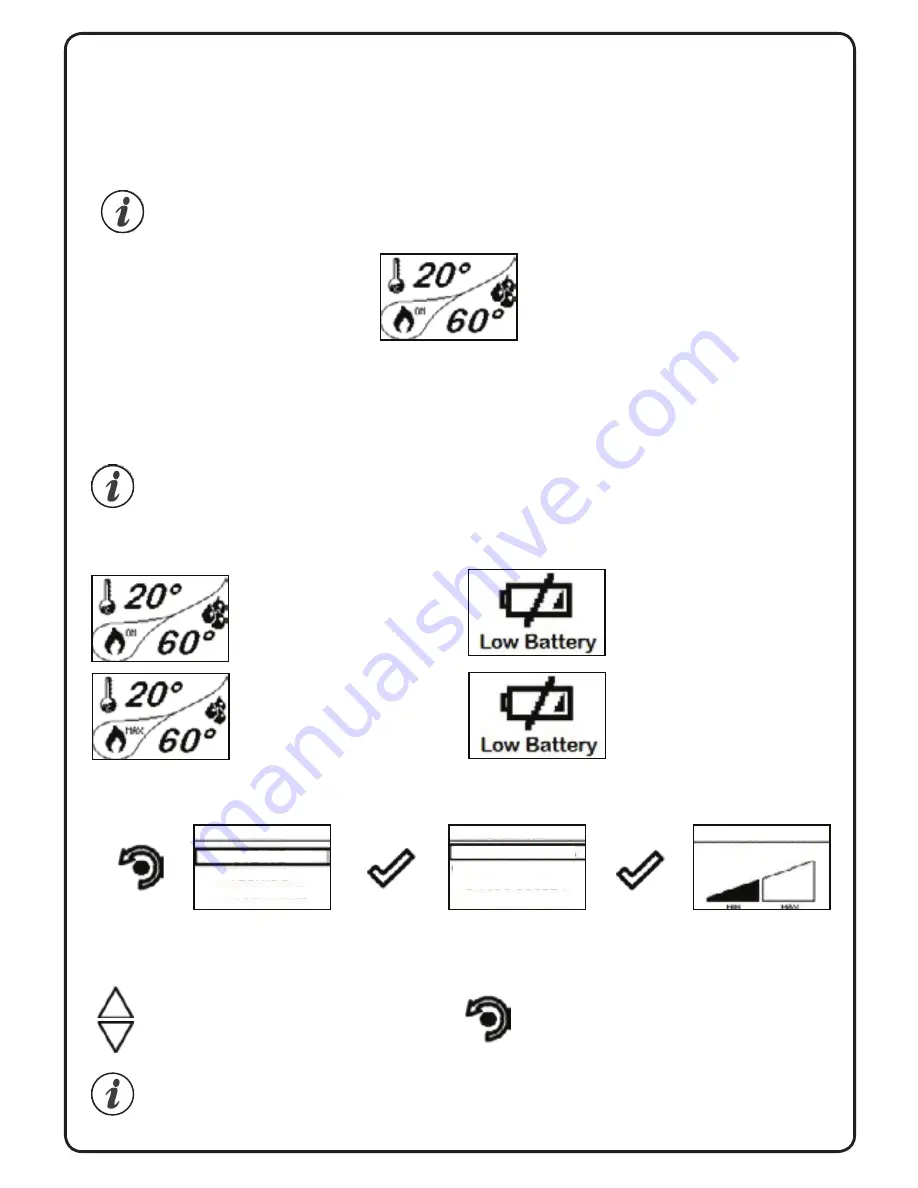

On the display of the handheld set appears the following:

Press and hold the ON/OFF button to turn off the stove and reset any alarms triggered. If the In case the infeed screw operations

described above have not been executed, the stove may fail to turn on.

Empty the brazier, reset the alarm and turn the stove on again. If the stove still fails to turn on, make sure the grate is perfectly fixed

to the support base; also check that there are no deposits that prevent the air to flow correctly and promote the ignition.

If the problem persists, contact the support service.

Changing the power of the stove

The message “ADJUST THE RDS SYSTEM” indicates that the initial parameter testing and calibration procedure has

been completed unsuccessfully. This indication does not block the stove (see section WARNING POP-UP).

Sequence of ignition phases

SWITCH-ON- initial pellet loading

phase;

WAIT FLAME - flame development

wait phase;

FLAME PHASE - flame

stabilization and reduction of

combustion inside the brazier;

WORK - operating phase

described in the dedicated chapter;

If the battery is empty, inside the “drop”

will be displayed a symbol indicating

the “almost empty” state of the same,

maintaining the handheld unit functions

active.

As soon as the level of the battery

prevents the radio communication the

handheld set displays on full screen the

picture of empty battery and all device

functions are locked until the batteries

are replaced

What happens if the batteries are empty?

For models with automatic cleaning system, the active stove enables a cleaning cycle of the brazier upon ignition and before

IGNITION. In the event of FAILED IGNITION, it is not necessary to remove the unburnt pellet from the inside of the brazier

before turning on the stove again. As soon as the user restarts the stove, the operating system runs the operation without

enabling the cleaning device and without reactivating the pellet loading phase.

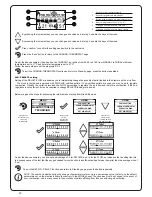

Press the key

“access menu” to

access the

MENU page

Press the key

“confirm”

to access the

USER page

Press the key

“confirm”

to access the

POWER SETTING page

Use the UP/DOWN keys to change the operating power.

By pressing the following key you will confirm the data

and go back to USER MENU

The power can be selected only when the stove is operating Upon every start-up, the stove operates with maximum power in order to

ensure greater heat input to the heating system.

Select the control type

Comfort Clima on t°C

Water or room temperature

using the key

UP/DOWN key

“V” key to confirm the

selection

MENU

USER

MANUFACTURER’S

TECHNICIAN

USER

POWER SETTING

POWER SELECTION

CHRONOTHERMOSTAT

SCREW LOADING

SET AIR-PELLET

MENU

USER

TECHNICIAN

USER

USER

POWER SETTING

STOVE STATE

CHRONOTHERMOSTA

COMFORT CLIMA

COMFORT CLIMA

COMFORT CLIMA

AIR

WATER

COMFORT CLIMA DELTA

COMFORT CLIMA DELTA

SHUTDOWN DELAY

SHUTDOWN DELAY

COMFORT CLIMA

COMFORT CLIMA

SCREW LOADING

SETTINGS

SET AIR-PELLET

ENABLE COMFORT

ENABLE COMFORT

ENABLE COMFORT

ENABLE COMFORT

ENABLE COMFORT

ENABLE COMFORT

COMFORT CONTROL

COMFORT CONTROL

COMFORT CONTROL

COMFORT CONTROL

RESTART DELTA

RESTART DELTA

RESTART DELTA

RESTART DELTA

SHUTDOWN DELAY

SHUTDOWN DELAY

SHUTDOWN DELAY

SHUTDOWN DELAY

MANUFACTURER’S

Manuale utente PALMARE IDRO TOUCH RADIO

Manuale utente PALMARE IDRO TOUCH RADIO

Pag.26

Pag.27

Vers. 01 del 07/04/15

Vers. 01 del 07/04/15

Operating phases of the appliance

During the work phases, the appliance is aimed at reaching the room/water temperature set by the user;

when one of these conditions is met, the stove switches to MODULE WORK phase, in which fuel consumption is minimised.

Modulation

Should it be necessary to measure the room temperature using an external thermostat (optional), the latter must be

connected to the dedicated connector to the rear of the stove; therefore, the user will be able to enable temperature reading

in the dedicated menu “SETTINGS - ENABLE THERMOSTAT”. On display appears the writing TON / TOFF based on

thermostat request.

CONNECT AN EXTERNAL THERMOSTAT WITH A SIMPLE DRY CONTACT, THEREFORE, NOT POWERED.

MOREOVER, WE RECOMMEND YOU USE A THERMOSTAT WITH A MINIMUM OFFSET OF 3°C

IF YOU INTEND TO USE THE COMFORT CLIMA FUNCTION.

The activation of this function enables the stove to reduce pellet consumption by activating the modulation phases, after the desired

temperature has been reached. Subsequently, the stove checks that the temperature is maintained steady for a preset time. If this

condition is met, it automatically switches off, and on display appears the writing ECO. The stove turns on again when the temperature

drops below the set threshold.

Below are given the steps for accessing the relative menu.

Comfort climate

Press the key

“access menu” to

access the

MENU page

Press the key

“confirm”

to access the

USER page

Press the key “selection” for

several times

to go to the second

page of the USER menu

and select

CLIMATE COMFORT.

Once you have accessed the Climate Comfort menu, it is possible to operate on the 4 types of settings dedicated to the function:

Press the key for several times until the Stand-by page is displayed.

Setting ambient and boiler water temperature:

Set the two values following the indications given in the chapter “Description of the display”

Turning the device on

Keep the key ON/OFF pressed for a few seconds to turn on the stove.

On the display of the handheld set appears the following:

Press and hold the ON/OFF button to turn off the stove and reset any alarms triggered. If the In case the infeed screw operations

described above have not been executed, the stove may fail to turn on.

Empty the brazier, reset the alarm and turn the stove on again. If the stove still fails to turn on, make sure the grate is perfectly fixed

to the support base; also check that there are no deposits that prevent the air to flow correctly and promote the ignition.

If the problem persists, contact the support service.

Changing the power of the stove

The message “ADJUST THE RDS SYSTEM” indicates that the initial parameter testing and calibration procedure has

been completed unsuccessfully. This indication does not block the stove (see section WARNING POP-UP).

Sequence of ignition phases

SWITCH-ON- initial pellet loading

phase;

WAIT FLAME - flame development

wait phase;

FLAME PHASE - flame

stabilization and reduction of

combustion inside the brazier;

WORK - operating phase

described in the dedicated chapter;

If the battery is empty, inside the “drop”

will be displayed a symbol indicating

the “almost empty” state of the same,

maintaining the handheld unit functions

active.

As soon as the level of the battery

prevents the radio communication the

handheld set displays on full screen the

picture of empty battery and all device

functions are locked until the batteries

are replaced

What happens if the batteries are empty?

For models with automatic cleaning system, the active stove enables a cleaning cycle of the brazier upon ignition and before

IGNITION. In the event of FAILED IGNITION, it is not necessary to remove the unburnt pellet from the inside of the brazier

before turning on the stove again. As soon as the user restarts the stove, the operating system runs the operation without

enabling the cleaning device and without reactivating the pellet loading phase.

Press the key

“access menu” to

access the

MENU page

Press the key

“confirm”

to access the

USER page

Press the key

“confirm”

to access the

POWER SETTING page

Use the UP/DOWN keys to change the operating power.

By pressing the following key you will confirm the data

and go back to USER MENU

The power can be selected only when the stove is operating Upon every start-up, the stove operates with maximum power in order to

ensure greater heat input to the heating system.

Select the control type

Comfort Clima on t°C

Water or room temperature

using the key

UP/DOWN key

“V” key to confirm the

selection

MENU

USER

MANUFACTURER’S

TECHNICIAN

USER

POWER SETTING

POWER SELECTION

CHRONOTHERMOSTAT

SCREW LOADING

SET AIR-PELLET

MENU

USER

TECHNICIAN

USER

USER

POWER SETTING

STOVE STATE

CHRONOTHERMOSTA

COMFORT CLIMA

COMFORT CLIMA

COMFORT CLIMA

AIR

WATER

COMFORT CLIMA DELTA

COMFORT CLIMA DELTA

SHUTDOWN DELAY

SHUTDOWN DELAY

COMFORT CLIMA

COMFORT CLIMA

SCREW LOADING

SETTINGS

SET AIR-PELLET

ENABLE COMFORT

ENABLE COMFORT

ENABLE COMFORT

ENABLE COMFORT

ENABLE COMFORT

ENABLE COMFORT

COMFORT CONTROL

COMFORT CONTROL

COMFORT CONTROL

COMFORT CONTROL

RESTART DELTA

RESTART DELTA

RESTART DELTA

RESTART DELTA

SHUTDOWN DELAY

SHUTDOWN DELAY

SHUTDOWN DELAY

SHUTDOWN DELAY

MANUFACTURER’S

6.7

Setting ambient and boiler water temperature:

6.8

Turning the device on

Summary of Contents for Pompeii

Page 14: ...Pull to clean exchanger tube bundle 12 5 8 How to Clean the Tubulators ...

Page 32: ...30 25 Page 16 7 Maintenance Record SIGNATURE WORK CARRIED OUT DATE ...

Page 44: ...42 1 2 x 4 2 12 How to mount the side panels ...

Page 50: ...48 38 4 Maintenance Record DATE WORK CARRIED OUT SIGNATURE 40 ...

Page 52: ......

Page 53: ......