Use and maintenance manual

RBV 8008 - RBV 8010

Pag.17

Rev.1 18/05/2021

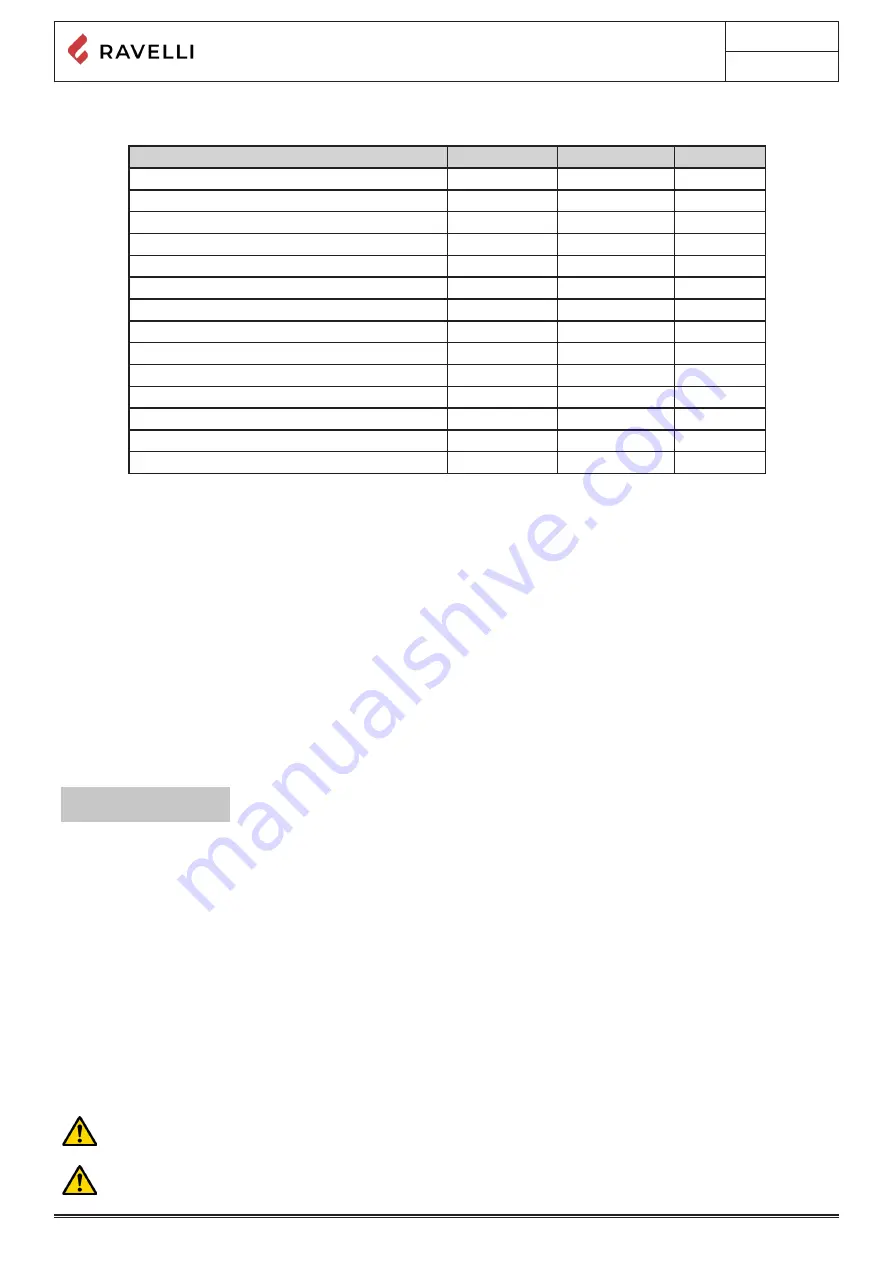

TECHNICAL CHARACTERISTICS

RBV 8008

RBV 8010

U

smoke outlet pipe Ø

80

80

mm

Max. heating volume

180

215

m

3

Heating input reduced - nominal

3,2 - 8,5

3,2 - 10,2

kW

Heating output reduced - nominal

3,0 - 7,7

3,0 - 9,0

kW

Electrical consumption during nominal heat output*

0,68 - 1,8

0,68 - 2,15

W

Electrical connection

420

420

V - Hz

Hopper capacity

50 - 230

50 - 230

kg

Hourly consumption

20

20

Kg/h

Loading interval

11 - 30

9 - 30

h

Red. - Nom. Yield

93,1 - 90,5

93,1 - 88

%

CO at 13% of O

2

0,021 - 0,004

0,021 - 0,004

%

Smoke flow

4,1 - 6,8

4,1 - 7,4

g/s

Minimum draft

10-0,1

10 - 0,1

Pa - mbar

Smoke temperature

71 - 132

71 - 157

°C

The data shown here is provided as a guideline and is not binding, and may change based on what type and quality of wood is used.

Ravelli reserves the right to make any changes in order to improve product performance.

Characteristics of the fuel

Wood pellet is a fuel made of pressed wood sawdust, often recovered from processing scraps of carpentries. The material used

cannot contain any extraneous substance such as, for example, glue, lacquer or synthetic substances.

The sawdust, once it has been dried and cleaned from impurities, is pressed using a die with holes: as a result of high pressure, the

sawdust heats up by activating the natural wood binders; this way the pellet maintains its shape even without adding artificial

substances.

Wood pellet density varies based on the type of wood and can exceed that of natural wood by 1.5 - 2 times.

The cylinders have a diameter of 6 mm and a variable length between 10 and 40 mm.

Their density is equal to approximately 650 kg/m

3

. Due to their low water content (< 10%) they have a high energy content.

The UNI EN ISO 17225-2:2014 standard (that replaces the EN PLUS standard) defines pellet quality by specifying three classes: A1,

A2 and B. Maintain fuels and other flammables at a suitable distance.

Ravelli recommends using wood pellet classified A1 and A2 according to the EN ISO 17225-2:2014 standard, or certified DIN PLUS

(more restrictive than the A1 class) or ONORM M 7135.

Pellet may be light or dark coloured, it is normally bagged into bags that show the name of the producer, the main characteristics

and classification according to standards.

! IMPORTANT

Pellets must be transported and stored in a dry area. Upon contact with humidity they

swell and become unusable: it is therefore necessary to protect them from humidity, both

during transport and during storage.

Non-permitted fuels

We recommend not using the following materials as fuel:

•

wood

•

treated wood (painted, lacquered, glued wood etc.);

•

sawdust or chips

•

liquid fuel

•

coal or other fossil fuels

•

plastic and derivatives

•

treated paper and cardboard

•

waste

•

fuels that release toxic or polluting substances

Using these fuels, on top of being forbidden due to the emission of polluting and harmful substances, causes the stove to deteriorate

more rapidly and debris to accumulate in the stove and in the smoke evacuation system, thereby reducing performance and safety.

The gases produced by these fuels are dangerous for the environment and for your health!

Using fuel that is not compliant with the above will void the warranty.

Summary of Contents for RBV 8008

Page 2: ...RBV 8008 RBV 8010 MANUALE D USO E MANUTENZIONE...

Page 3: ......

Page 7: ...RBV 8010 RBV 8008 RBV 8010...

Page 9: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 50: ...RBV 8008 RBV 8010 MANUEL D UTILISATION ET D ENTRETIEN...

Page 51: ......

Page 55: ...RBV 8010 RBV 8008 RBV 8010...

Page 56: ......

Page 57: ......

Page 95: ......

Page 96: ......

Page 98: ...RBV 8008 RBV 8010 USE AND MAINTENANCE MANUAL...

Page 99: ......

Page 103: ...RBV 8010 RBV 8008 RBV 8010...

Page 104: ......

Page 105: ......

Page 143: ......

Page 144: ......

Page 146: ...RBV 8008 RBV 8010 BEDIENUNGS UND WARTUNGSHANDBUCH...

Page 147: ......

Page 151: ...RBV 8010 RBV 8008 RBV 8010...

Page 152: ......

Page 153: ......

Page 191: ......

Page 192: ......

Page 194: ...RBV 8008 RBV 8010 MANUAL DE USO Y MANTENIMIENTO...

Page 195: ......

Page 199: ...RBV 8010 RBV 8008 RBV 8010...

Page 200: ......

Page 201: ......

Page 238: ......

Page 239: ......

Page 240: ......

Page 242: ...HANDLEIDING VOOR GEBRUIK EN ONDERHOUD RBV 8008 RBV 8010...

Page 243: ......

Page 249: ......

Page 290: ......

Page 291: ......

Page 292: ......