016-0236-001 Rev. C

39

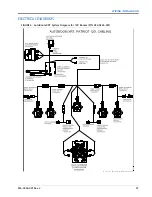

WIRING INSTALLATION

CONNECT THE HARNESS TO THE POWER/CAN CONTROLS

90’-100’ BOOM

NOTE:

While making the following connections, be aware of the cable routing and avoid possible cable

pinch points and other issues.

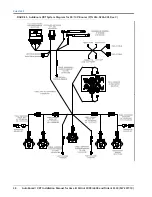

1. Plug gray 23 pin plug on the XRT cable (P/N 115-0235-100) to the mating connector on the bottom of the REM

node.

2. Plug black 23 pin plug on the XRT cable to the mating connector on the bottom of the REM node.

3. Plug black 35 pin plug on the XRT cable to the mating connector on the bottom of the REM node.

4. Route the connector labeled ABM along the machine hoses and towards the ABM node.

5. Connect the connector labeled ABM to the AutoBoom node.

6. Use the provided 12-pin green DTM plug to protect the unused connector of the ABM node.

FIGURE 6. AutoBoom Cable Connected to Node

7. Connect the RIGHT CYLINDER POSITION plug to the 4-pin receptacle on the Superseal Position Sensor cable

(P/N 115-0235-069).

8. Route and connect the other end of the cable (P/N 115-0235-069) to the previously installed tilt sensor.

9. Repeat step 7 though step 8 for the left cylinder position plug.

10. Connect the CENTER RACK ANGULAR POSITION plug to the 4-pin receptacle on the Superseal Position Sensor

cable (P/N 115-4010-069).

11. Route and connect the other end of the cable (P/N 115-0235-069) to the previously installed center rotation

sensor.

12. If dampers were installed, connect the plug labeled DAMPER 1 to the mating receptacle on the top damper.

13. If dampers were installed, connect the plug labeled DAMPER 2 to the mating receptacle on the bottom

damper.

14. Connect the RIGHT SOLENOID plug on the XRT cable to port 4B on the AutoBoom XRT valve.

15. Connect the LEFT SOLENOID plug on the XRT cable to port 4A on the AutoBoom XRT valve.

16. Connect the LEFT PROP plug on the XRT cable to port 5A on the AutoBoom XRT valve.