PAGE 16/35 | Installation manual | 016-8000-028EN | Rev. A1

Raven Industries Inc.

STEERING SYSTEM INSTALLATION | CRX + RS1 | RAVEN EUROPE GENERIC

Hint!:

In case the wheels of the tractor are steering,

when the hydraulics of the tractor are operated;

a checkvalve should be mounted in the load

sense line from the manifold. The non-return

valve should let oil pass from the manifold to

the check valve/pump and should block in

opposite direction.

Hint!:

A shuttle valve for CNH tractors can be provided

by Raven Europe (part no. 13348001014) or the

local CNH dealer (part no. 82018814).

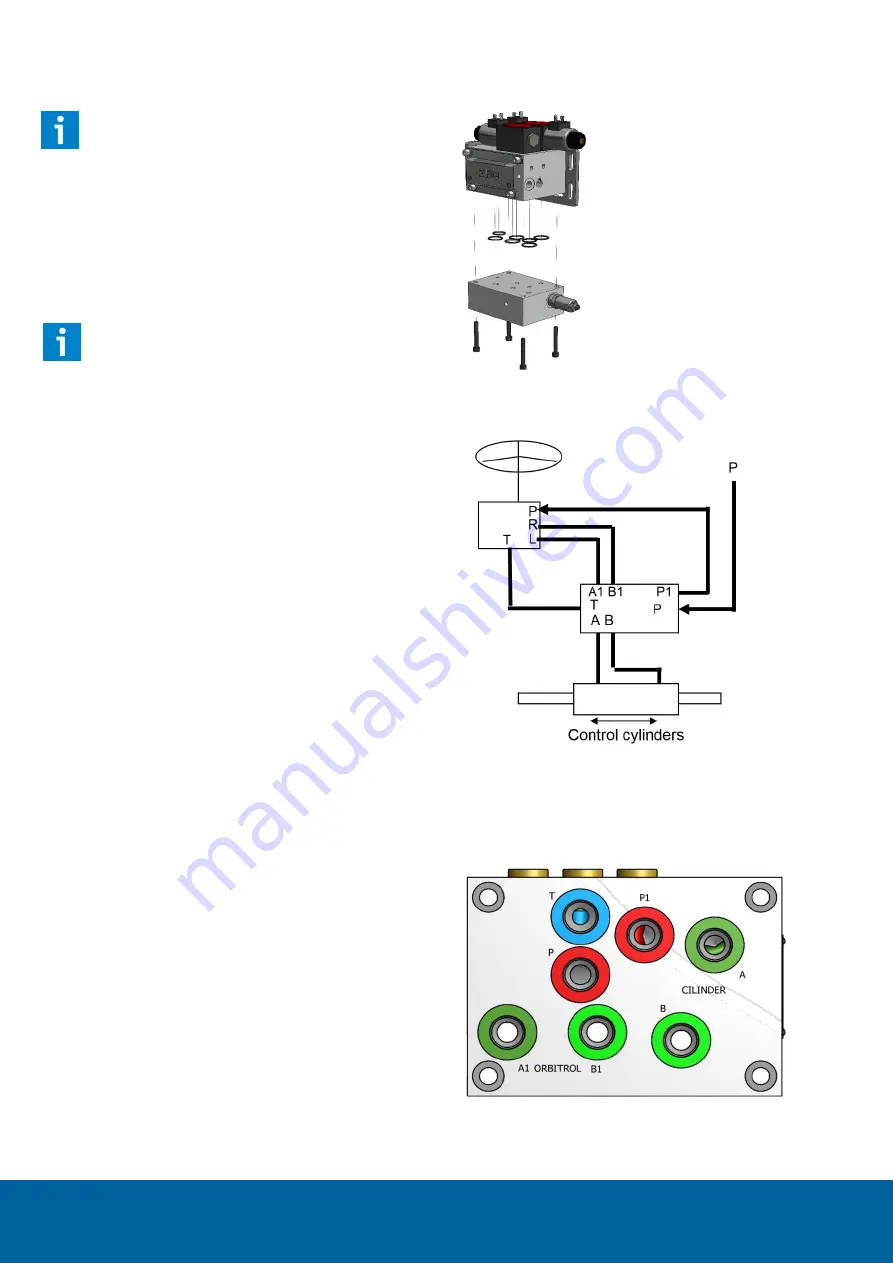

1.2.4

HYDRAULIC INSTALLATION OPEN CENTER

The manifold v3 open center consists of the standard

load sense manifold v3 with an add-on open center

part (Figure 8). Ensure the add-on is mounted the

correct way.

The pressure line that normally runs from the hydraulic

pump to the steering orbitrol, should be connected to

the P of the add-on open center part. Then connect a

line between P1 of the manifold and the pressure line

of the orbitrol. Connect the T of the manifold to a tank

inlet (Figure 9Figure 9 and Figure 10).

Connect the hoses leading from the orbitrol to A1 and

B1 on the manifold. Connect the hoses to the steering

cylinders to A and B of the manifold (Figure 9Figure 9

and Figure 10Figure 10).

FIGURE 8 ADD-ON PART OF THE OPEN

CENTER MANIFOLD.

FIGURE 9 OPEN CENTER CONNECTION

CIRCUIT.

FIGURE 10 CONNECTIONS OF THE HYDRAULIC

OPEN CENTER MANIFOLD.