Chapter 4

36

Viper Pro Installation & Operation Manual

3.

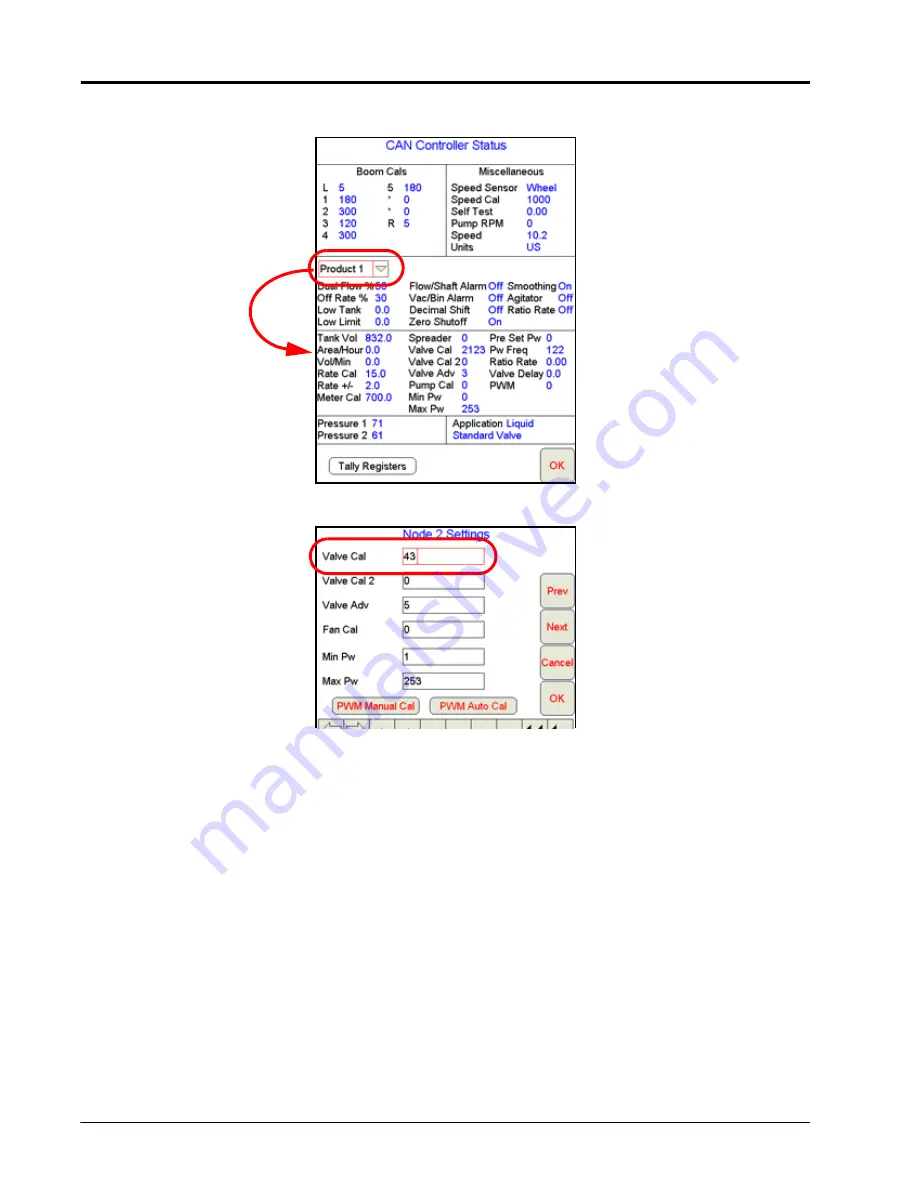

Select one of control channels currently assigned to the product controller node and touch within the

Product Control Settings

area.

4.

The first node settings screen for the selected control channel will be displayed. Touch the

Next

button

along the right side of the screen to display the second node settings screen.

5.

Touch the displayed valve cal value. Using the on-screen keyboard, enter a valve cal value of ‘900#’ where

# is the desired number of control channels assigned to the product controller node.

For example, enter a value of ‘9005’ in the valve cal to enable all five control channels on the air cart node.

6.

Touch the

OK

button until the Viper Pro main screen is displayed.

7.

Select the

Menu

button in the lower, right corner of the display and select the

Exit

,

Exit to Menu

options.

8.

When the Program Selection Menu screen displays, select the

Sprayer/Spreader

option to restart the Viper

Pro application. The CAN Initialization Results screen will display again.

9.

Verify that the appropriate control channels are displayed before touching the

Start Viper

button. Review

Configuring a Product Controller Node

section on page 35 to disable control channels on the product

controller node.

Summary of Contents for Viper Pro

Page 1: ... Software Version 3 10 Viper Pro Installation Operation Manual ...

Page 42: ...Chapter 3 32 Viper Pro Installation Operation Manual ...

Page 132: ...Chapter 6 122 Viper Pro Installation Operation Manual ...

Page 138: ...Chapter 7 128 Viper Pro Installation Operation Manual ...

Page 180: ...Manual No 016 0171 122 Rev I 170 Advanced Settings and Features ...

Page 194: ...Chapter 9 184 Viper Pro Installation Operation Manual ...

Page 214: ...Chapter 11 204 Viper Pro Installation Operation Manual ...

Page 262: ...Appendix B 252 Viper Pro Installation Operation Manual ...

Page 276: ...Appendix F 266 Viper Pro Installation Operation Manual ...

Page 284: ...Appendix I 274 Viper Pro Installation Operation Manual ...

Page 292: ...Appendix J 282 Viper Pro Installation Operation Manual ...

Page 299: ......