20

Allowing for the acceptable pressure loss of 1

mbar across the installation pipework, it can be

assumed that a minimum permitted operating

pressure of 18 mbar (nat gas) will be delivered

to the inlet of the appliance. (reference BS

6400-1 Clause 6.2 Pressure Absorption).

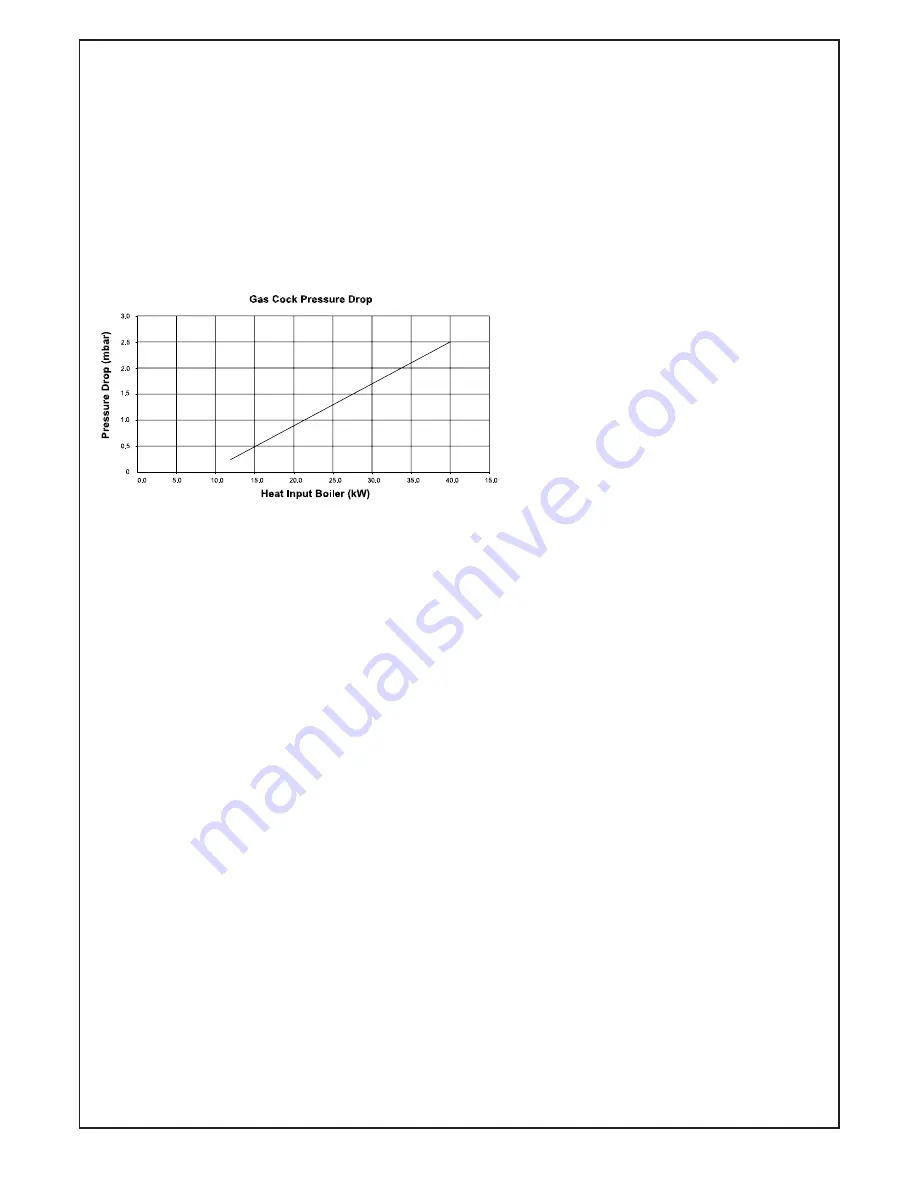

The external gas cock could further reduce the

operating pressure when measured at its

d at its test

point. The pressure drop is relative to the heat

input to the boiler (kW), refer to graph below.

4.7 FLUE SYSTEM

The terminal should be located where dispersal

of combustion products is not impeded and with

due regard for the damage or discolouration

that might occur to building products in the

vicinity (section 4.10).

The terminal must not be located in a place

ocated in a place

where it is likely to cause a nuisance in cold

where it is likely to cause a nuisance in cold

and/or humid weather as water vapour may

and/or humid weather as water vapour may

condense on leaving the flue terminal.

condense on leaving the flue terminal.

The effect of such pluming must be

The effect of such pluming must be

considered.

considered.

The terminal must not be closer than 25 mm

The terminal must not be closer than 25 mm

(1 inch) to any combustible material for

(1 inch) to any combustible material for

protection of combustibles, refer to BS 5440.1.

Where a flue terminal is installed less than 1000

mm from a plastic, or painted gutter; or 500 mm

from painted eaves, an aluminium shield 1000

mm long, should be fitted to the underside of

the gutter or painted surface.

Pluming will occur at the terminal so, where

possible, terminal positions which could cause

a nuisance should be avoided.

The flue must be installed in accordance with

the recommendations of BS 5440: Part 1.

IMPORTANT NOTES:

For greater fl ue lengths see alternative fl ue

instructions. Flue must be positioned in a

place not likely to cause a nuisance from

pluming.

IMPORTANT NOTICE:

If the fl ue terminates

below a balcony, above the ground, above a

fl at roof to which people have access, then

a suitable

terminal guard

must be fi tted if

less than 2 metres high. The part number is

less than 2 metres high. The part number is

PRO110100.

PRO110100.

Fit only recommended

Fit only recommended

FLUE TERMINAL

FLUE TERMINAL

GUARD

GUARD

b

by securing concentrically around

terminal with screws.

Available on request from:

Ravenheat Manufacturing ltd

Chartists Way, Morley, Leeds,

West Yorkshire

ENGLAND LS27 9ET - UK

Tel. 0113 252 7007

IMPORTANT:

The following notes are intended for general

guidance.

The boiler MUST be installed so that the

terminal is exposed to external air.

It is important that the position of the terminal

allows the free passage of air across it at all

times.

times.

Minimum acceptable spacing from the terminal to

obstructions and ventilation openings are

specifi ed in section 4.10.

Note positions:

Due to the terminal design,

installation is possible with clearances less than

those specifi ed in BS 5440, Part 1

NOTE:

The flue must be terminated in a place not

likely to cause a nuisance.

A concentric vertical flue kit is available for

longer flueing applications (see table 5 page

26).

For further details see vertical flue installation

instructions.

4.8 AIR

SUPPLY

The following notes are intended for general

guidance.

The room sealed fan flued boiler does not

require a permanent air vent for combustion air

supply.

Where installed in a cupboard or compartment

ventilation is not required.

4.9

WATER CIRCULATION (Central heating)

Detailed recommendations are given in BS6798

2009/5449:1990 - BSEN12828 - BSEN12831

- BSEN14336 (for smallbore and microbore

central heating systems). The following notes

are given for general guidance.

Summary of Contents for CS 80 T

Page 2: ...2 ...

Page 21: ...21 4 10 FLUE TERMINAL POSITION ...

Page 54: ...10 ELECTRICAL SYSTEM DIAGRAM 54 Fig 56 ...

Page 55: ...55 11 SPARE PARTS Fig 57 ...

Page 61: ...61 ...

Page 62: ...62 ...

Page 64: ...64 FLOWCHART FOR CO LEVEL AND COMBUSTION RATIO CHECK ON COMMISSIONING A CONDENSING BOILER ...

Page 65: ...65 12 1 ANALYSER CHECK LIST ...