4.19 WATER TREATMENT

This boiler has an aluminium and stainless steel

heat exchanger, Ravenheat recommend the use

of FERNOX or SENTINEL, or other treatment

products recognised by Ravenheat which must

be used in accordance with the manufacturer’s

manufacturer’s

instructions.

instructions.

4.20

HARD WATER AREAS

4.20

HARD WATER AREAS

If the area of installation is recognised as

If the area of installation is recognised as

a hard water area, it is recommended that a

a hard water area, it is recommended that a

suitable water treatment device is installed on

suitable water treatment device is installed on

the mains supply.

the mains supply. The water hardness can be

determined by using the standard test paper or

by referring to local water authority.

4.21 DOMESTIC

WATER

The domestic hot water must be in accordance

with the relevant recommendations of BS 5546.

Copper tubing to BS 2871-1 is recommended

for water carrying pipework and MUST be used

for pipework carrying potable water.

4.22 ELECTRICAL

SUPPLY

Warning: this appliance must be earthed

External wiring to the appliance must be

carried out by a competent person and be in

accordance with the current I.E.E. Regulations

and local regulations which apply. Ravenheat

boiler is supplied with a connection to a 230 V

with a connection to a 230 V

~ 50 Hz single phase supply.

~ 50 Hz single phase supply.

The supply must be fused at 3 A.

The supply must be fused at 3 A.

NOTE: The method of connection to the

NOTE: The method of connection to the

electricity supply MUST facilitate complete

electricity supply MUST facilitate complete

electrical isolation of the appliance, by the

electrical isolation of the appliance, by the

use of a fused, double pole isolator, having

use of a fused, double pole isolator, having

a contact separation of at least 3 mm in all

a contact separation of at least 3 mm in all

poles. The point of connection to the electricity

poles. The point of connection to the electricity

supply must be readily accessible and

supply must be readily accessible and adjacent

to the appliance except, where the appliance is

installed in a bathroom.

The current electrical IEE Wiring

regulations must be followed in GB.

5 INSTALLATION

5.1 WARNING

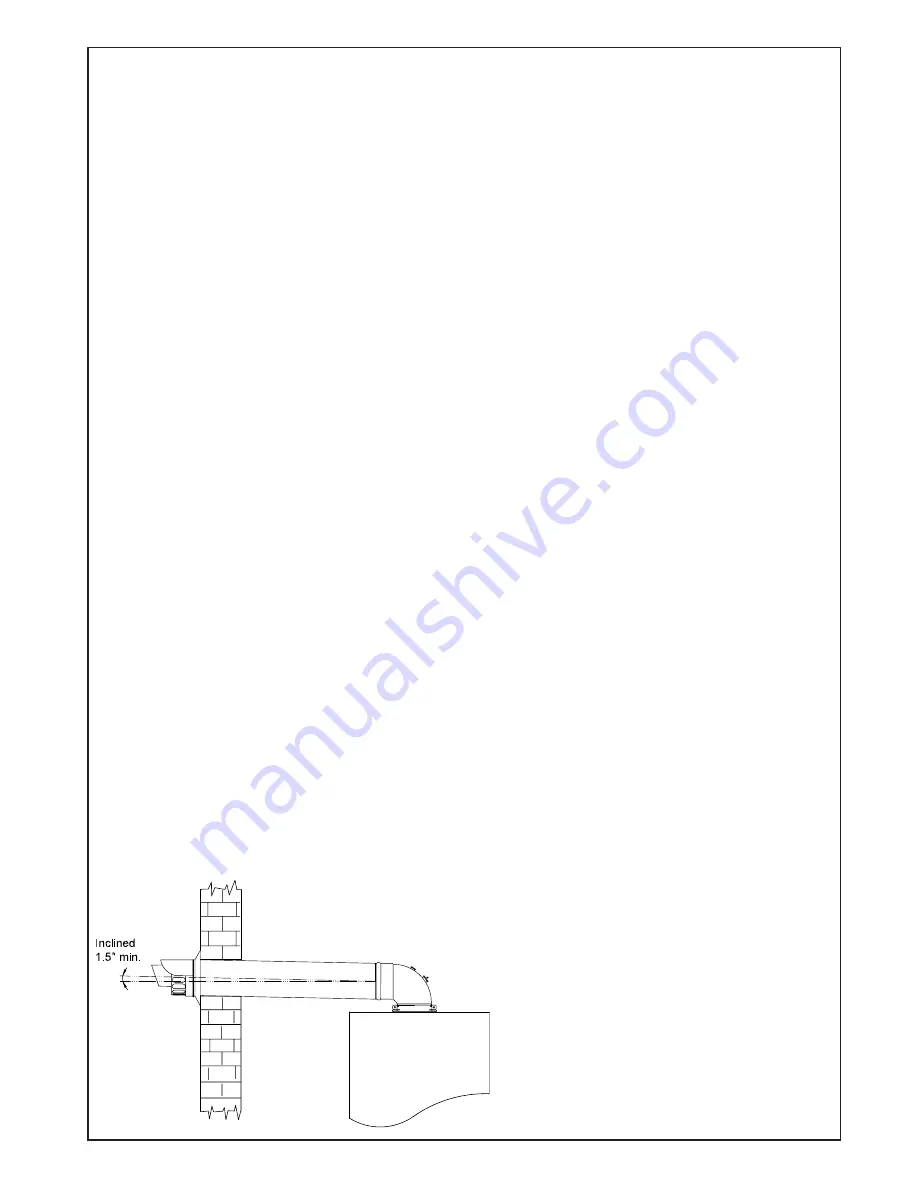

It is MOST IMPORTANT that this appliance is

installed in a HORIZONTAL POSITION, with

the flue air duct passing through the wall.

Make sure the flue is at a 1.5° incline, rising

from the boiler with 50 mm.

Flue terminal diagram states 1.5° - 25 mm,

fall back on flue (fig. 9).

5.2 DELIVERY

The appliance carton contains:

The appliance carton contains:

a) Boiler fully assembled with fl ue adaptor

a) Boiler fully assembled with fl ue adaptor

b) Installation instructions,

b) Installation instructions,

user instructions and Benchmark log

user instructions and Benchmark log

book

book

c) White paper template

c) White paper template

d) Guarantee card

d) Guarantee card

e) Polythene bag containing:

e) Polythene bag containing:

-

-

1-15 mm gas service valve

1-15 mm gas service valve

- 2-22 mm compression ball valves

- 2-22 mm compression ball valves

complete with 3/4” washers

complete with 3/4” washers

- 1-15 mm compression ball valves

- 1-15 mm compression ball valves

complete with 1/2” washers

complete with 1/2” washers

- 1- 15 mm compression ball valve

- 1- 15 mm compression ball valve

- 2 fi xing bolts and wall plugs

- 2 fi xing bolts and wall plugs

IMPORTANT NOTES:

This appliance will produce a plume of

condensation in cool weather. This is due to

the High Effi ciency and hence low fl ue gas

temperature of the boiler. A plume management kit

is available. (see section 5.6 fi g 12)

5.3

UNPACKING OF BOILER

IMPORTANT:

With regard to the Manual Handling

Operations, 1992 Regulations, the following

lift operation exceeds the recommended

weight for a one man lift.

- Stand the boiler carton upright.

- Open the top of the carton.

- Rest the carton on the fl oor

(keeping the fl aps open).

- Turn the carton over with the boiler inside

and then pull the carton up away from

the boiler.

- Rest the boiler on its back on the

fl oor to prepare it for installation.

5.4

POSITIONING OF THE BOILER

Unscrew the two lower screws that secure the

front panel and pull forward and lift up

(fig. 39).

Unscrew the 4 screws that fasten the lower

grating on the casing and remove it from the

bottom of the casing.

Make sure the casing and screws are put to

one side in a safe place.

Fig.9

25

Summary of Contents for CS 80 T

Page 2: ...2 ...

Page 21: ...21 4 10 FLUE TERMINAL POSITION ...

Page 54: ...10 ELECTRICAL SYSTEM DIAGRAM 54 Fig 56 ...

Page 55: ...55 11 SPARE PARTS Fig 57 ...

Page 61: ...61 ...

Page 62: ...62 ...

Page 64: ...64 FLOWCHART FOR CO LEVEL AND COMBUSTION RATIO CHECK ON COMMISSIONING A CONDENSING BOILER ...

Page 65: ...65 12 1 ANALYSER CHECK LIST ...