-

IMPORTANT:

After completing any servicing or

replacement of gas carrying components it

is essential that a test for gas soundness

is always carried out along with functional

checks in operation.

7.2

TO INSPECT AND CLEAN THE

APPLIANCE

Before carrying out the cleaning

operation, cover the electrical control

panel with a piece of waterproof material

to protect it from debris.

Inspect the heat exchanger for any

blockage. Deposits of any material should

be brushed away using a soft brush.

NOTE:

Do not use brushes with metallic

bristles.

Examine internal pipe-work connections

and automatic air vent for any water leaks

and rectify if necessary.

Examine and remove loose debris from

Examine and remove loose debris from

the combustion chamber using a soft

the combustion chamber using a soft

brush and vacuum cleaner. Carefully flush,

brush and vacuum cleaner. Carefully flush,

by spraying water at any remaining debris

by spraying water at any remaining debris

through the condensate trap.

through the condensate trap.

(Ensure the water is kept away from

(Ensure the water is kept away from

electrical components).

electrical components).

Inspect the siphonic condensate trap for

Inspect the siphonic condensate trap for

a blockage. Remove the cap at the base

a blockage. Remove the cap at the base

of the condensate trap. Remove an

of the condensate trap. Remove any

debris found. Remove the float to clean it.

Any deposits should be flushed out.

Reassemble and refit the condensing

trap.

When refitting the cap ensure that a

watertight seal is achieved, but do not use

excessive force.

Examine the spark and sensing electrodes

for any mechanical damage. Clean away

any debris and check the spark and sensing

gap.

Examine flue duct and flue manifold and

ensure that there is no obstruction.

Examine the gasket at the entry into the

flue manifold.

It is essential that a good seal is made at

the outlet to the flue manifold, renew this

gasket if there is any sign of damage or

deterioration.

8 REPLACEMENT OF PARTS

8.1 GENERAL

Replacement of parts must be carried

out by a competent person.

Before replacing any parts the boiler should

be isolated from the mains electric supply

and the gas should be turned off at the

service cock on the boiler.

After replacing any parts always test for

After replacing any parts always test for

gas soundness and if necessary carry out

gas soundness and if necessary carry out

functional test of the controls.

functional test of the controls.

For replacement of parts, the front, and

For replacement of parts, the front, and

bottom panels of the boiler will need to be

bottom panels of the boiler will need to be

removed (it is not necessary to remove the

removed (it is not necessary to remove the

side panels as all parts are accessible from

side panels as all parts are accessible from

the front or beneath the boiler).

the front or beneath the boiler).

8.2

TO REMOVE THE BOILER PANELS

8.2

TO REMOVE THE BOILER PANELS

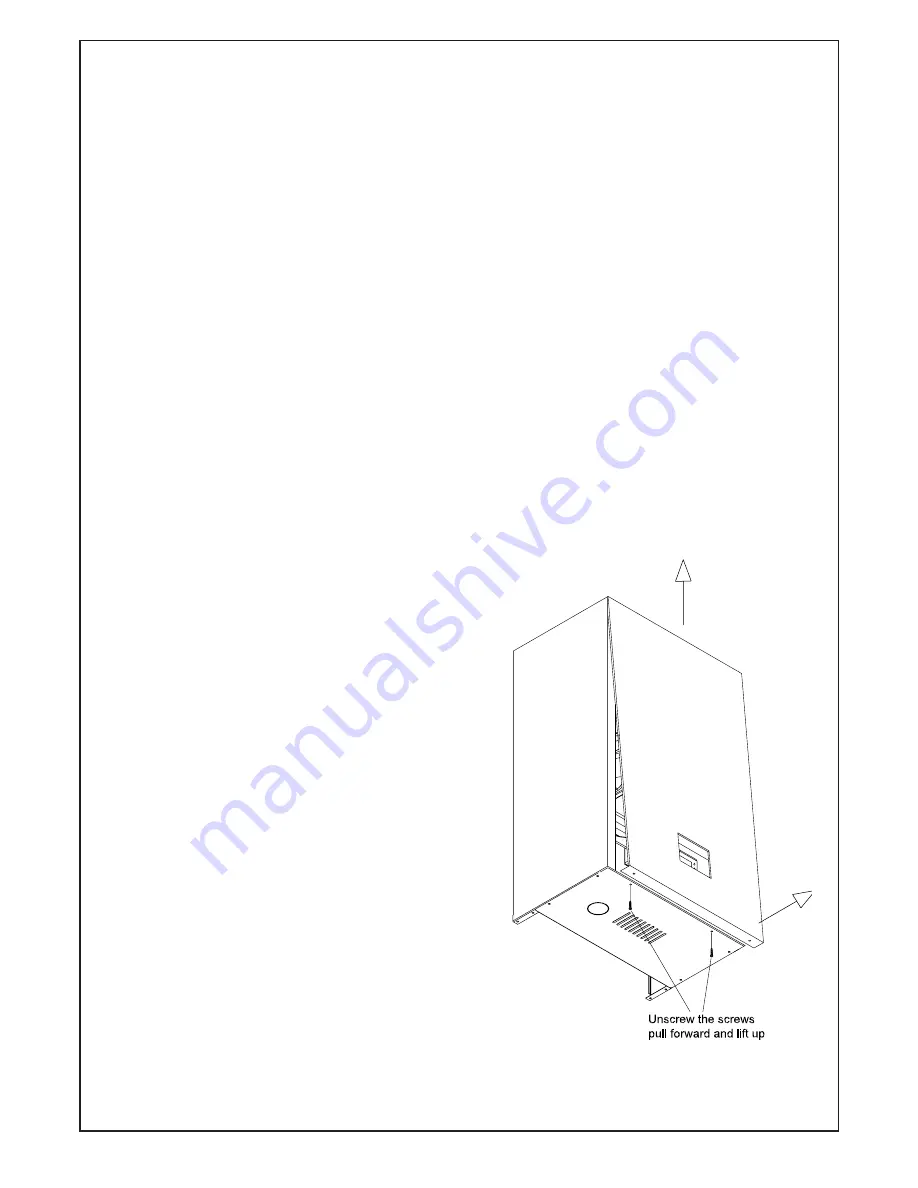

To remove the front panel unscrew the two

To remove the front panel unscrew the two

lower screws that secure the front panel to

lower screws that secure the front panel to

the boiler and lift off

the boiler and lift off

..

Fig. 39

45

Summary of Contents for CS 80 T

Page 2: ...2 ...

Page 21: ...21 4 10 FLUE TERMINAL POSITION ...

Page 54: ...10 ELECTRICAL SYSTEM DIAGRAM 54 Fig 56 ...

Page 55: ...55 11 SPARE PARTS Fig 57 ...

Page 61: ...61 ...

Page 62: ...62 ...

Page 64: ...64 FLOWCHART FOR CO LEVEL AND COMBUSTION RATIO CHECK ON COMMISSIONING A CONDENSING BOILER ...

Page 65: ...65 12 1 ANALYSER CHECK LIST ...