Supplied By www.heating spares.co Tel. 0161 620 6677

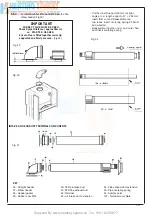

NOTE

The fl ue must be terminated in a place not

likely to cause a nuisance

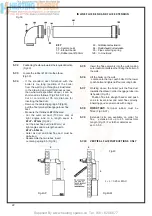

4.6.2

A concentric vertical fl ue kit is available, for

fl ueing applications up to a maximun height

of 40 metres.

For further details see vertical fl ue installation

instructions.

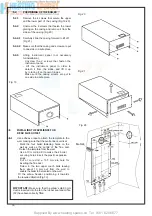

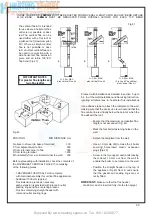

4.7 AIR

SUPPLY

4.7.1

The following notes are intended for general

guidance.

The room sealed fan fl ued boiler does not re

quire a permanent air vent for combustion air

supply.

Where installed in a cupboard or compartment

ventilation is not required.

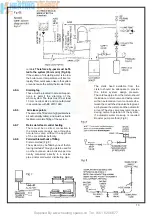

CONDENSATE DRAIN

A condensate drain is provided on the boiler

This drain must be connected to a drainage

point All pipework and fi ttings in the condesate

drainage system MUST be made of plastic-no

other materials may be used Discharge of

condensate DD X 189 1990 Y.

The drain outlet on the boiler is standard

3/4” (21 5 mm) push fi t overfl ow pipe.

NOTE:

Condensate drain pipework must

never be less than 15 mm.

Important:

any external runs must be carried

out in 1 1/4 (32 mm) wastepipe .

A fall of 2 5° (45 mm/m) all runs must have.

4.8

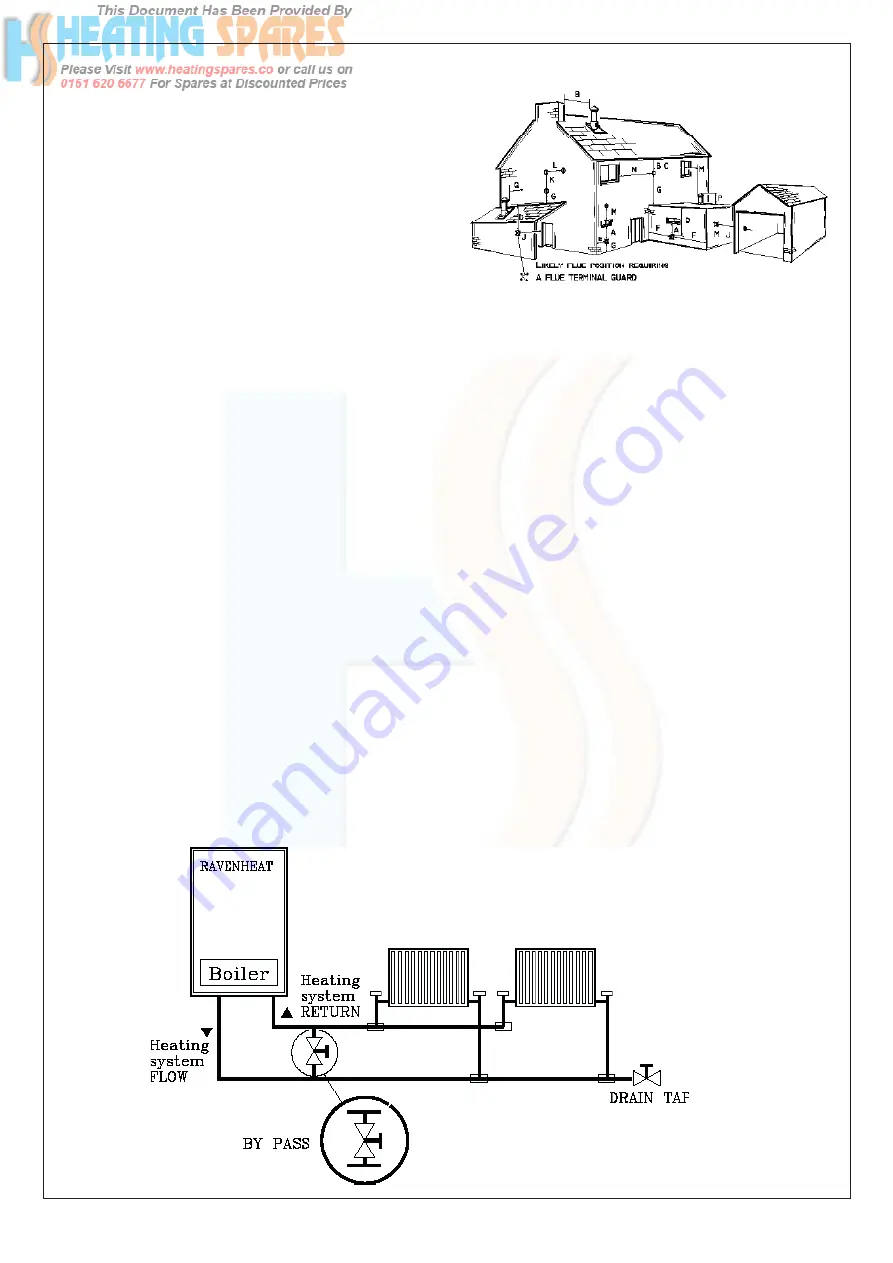

WATER CIRCULATION (central heating)

4.81

Detailed recommendations are given in BS

6798:1897/ 5449 : 1990 (for smallbore

and microbore central heating systems).

The following notes are given for general

guidance.

4.8.2 Pipework

Copper tubing to BS 2871 1.1.1971 is reco-

mended for water pipes Jointing should be

either with capillary soldered or with

compression

fi ttings.

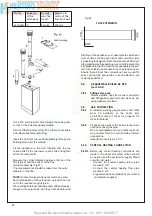

Where possible pipes should have a gradient

to ensure air is carried naturally to air release

points and water fl ows naturally to drain taps,

It should be ensured as far as possible that

the appliance heat exchanger is not a natural

collecting point for air.

Except where providing useful heat, pipes

should be insulated to prevent heat loss and

to avoid freezing Particular attention should

be paid to pipes passing through ventilated

spaces in roofs and under fl oors.

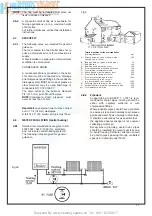

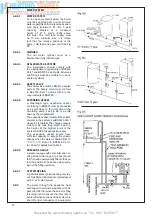

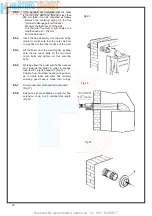

Fig 6

Terminal position for fan assisted boiler

(minimum distance)

mm

11

Fig.6A

A- Directly below an open window or other

300

opening (e.g. air brick)

B - Below gutters, soil pipes or drain pipes 75

C - Below eaves 150

D - Below balconies or car port roof 200

E - From vertical drain pipes and soil pipes 150

F - From internal or external corners 300

G - Above ground or below balcony level 300

H - From a surface facing a terminal 600

I -

From a terminal facing a terminal 1200

J - From an opening in the car port

(e.g. door window) into dwelling. 1200

K - Vertically from a terminal on the same wall 1500

L - Horizontally from a terminal on the same wall 300

M - From adjacent wall to flue 300

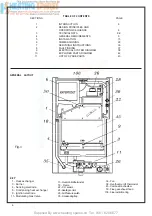

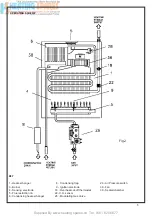

Summary of Contents for HE Primary AAA

Page 16: ...Supplied By www heating spares co Tel 0161 620 6677 17 Fig 18...

Page 31: ...Supplied By www heating spares co Tel 0161 620 6677 Fig 58 32 Fig 56 Fig 57...

Page 33: ...Supplied By www heating spares co Tel 0161 620 6677 34 Fig 60 Fig 61 Fig 62 Fig 63...

Page 42: ...Supplied By www heating spares co Tel 0161 620 6677 section 10 EXPLODED PARTS DIAGRAM 43...