Supplied By www.heating spares.co Tel. 0161 620 6677

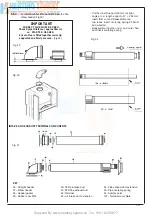

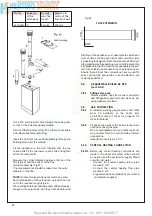

Fig 41

L

L

L

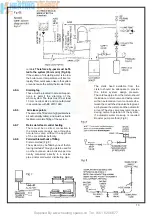

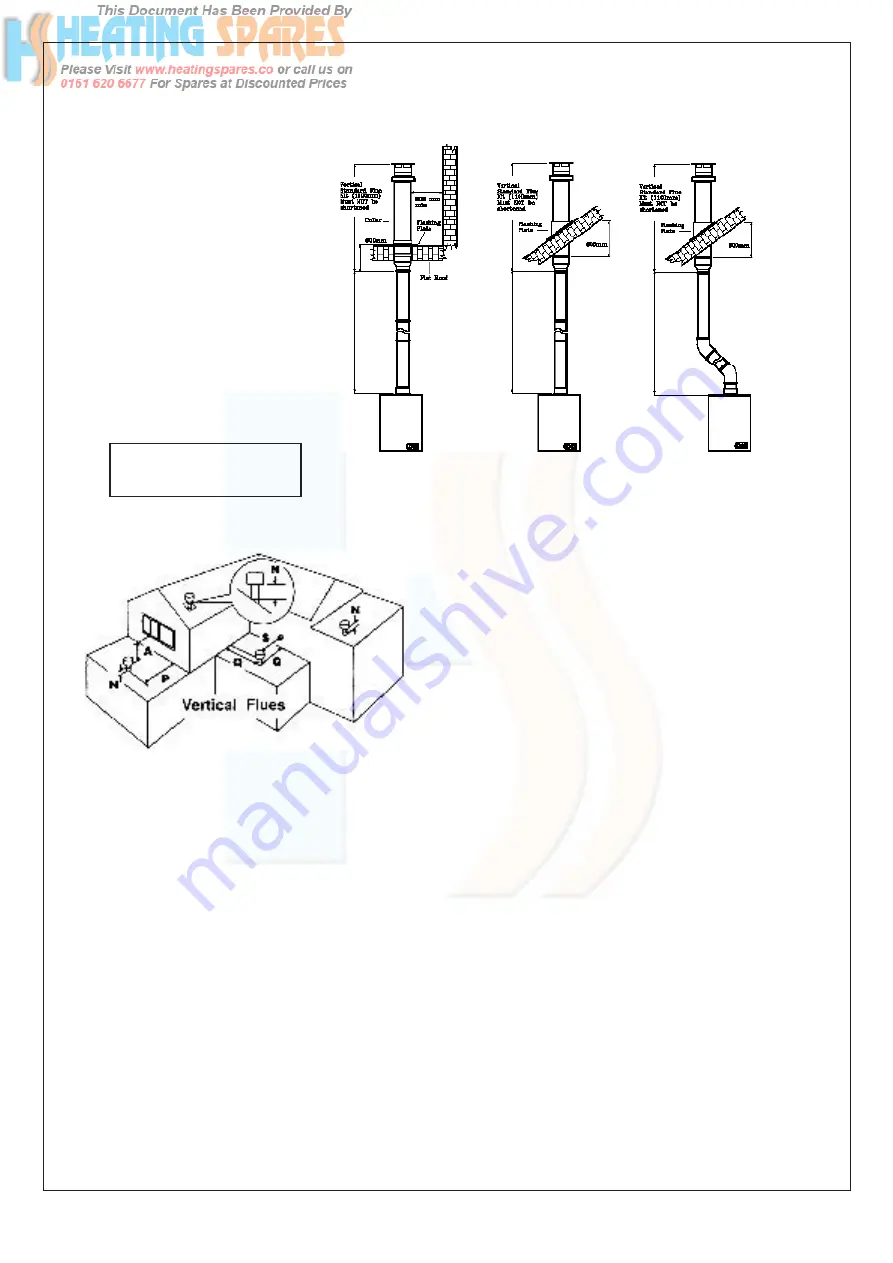

L = 3.0m MAX

plus Vertical Flue kit

L = 3.0m MAX

plus Vertical Flue kit

L = 2.25m MAX

(2 in line 45° bend Max)

plus Vertical Flue kit

23

INLINE FLUE BEND

- 1680 mm

MUST BE DEDUCTED FROM OVERALL LENGTH FOR EACH 90° BEND OBTUSE

FLUE BEND -

1680mm

MUST BE DEDUCTED FROM OVERALL LENGTH FOR EACH 135° BEND

The vertical fl ue kit is intended

for use where a horizontal fl ue

outlet is not possible or desi-

red The vertical fl ue can be

used either with a fl at roof or

a pitched roof (maximum pitch

60°) Where a straight vertical

fl ue is not possible or desi-

red, an offset vertical fl ue can

be used in conjunction with a

side horizontal fl ue extension

piece and an inline 135°/90°

fl ue bend (Fig 41)

IMPORTANT NOTES

For greater fl ue lengths see

twin fl ue leafl et

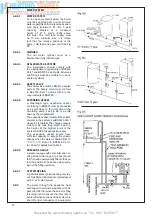

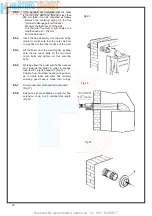

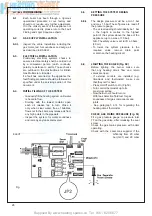

Fig 42

POSITION

MIN DISTANCE mm

N above roof level (to base of terminal)

300

P from adjacent wall to fl ue

300

Q from internal corner to fl ue

300

S from facing terminal

1,200

M horizontally from a vertical terminal to a wall

300

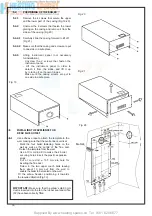

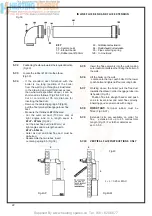

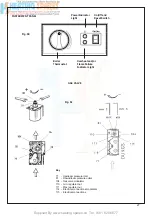

Before proceeding with installation check the contents of

the RAVENHEAT VERTICAL FLUE KIT, comprising

of the following pieces

- 1 RAVENHEAT VERTICAL FLUE complete

with terminal assembly (for vertical fl ue application).

- Additional 1000 mm (approx) .

Flue Extension pieces as necessary,

each extension is provided with inlet and outlet

sealing rings and fl ue centering bracket

- One box containing straight header with

inlet and outlet sealing rings.

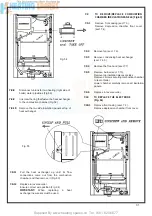

Proceed with installation as detailed in section 5 up to

5.4. 8 , of the main Installation and Servicing Instruction,

ignoring all references to horizontal fl ue installations

Use adhesive tape to attach the template to the wall,

making sure that the centre line is vertical and that the

fl ue centre line is virtually below the point at which the

fl ue will exit the roof.

- Ensure that the maximum permissible fl ue

length is not exceeded (Fig .42).

- Mark the four boiler fastening holes on the

wall.

- Detach the template from the wall.

- Use a 10 mm dia drill to make the 4 boiler

securing holes.Insert plastic expansion

plugs (Fig 29).

- Screw in the two upper coach bolts leaving

them about 10 mm out from the wall to

enable the boiler to be located on the wall.

- Position the straight header on the top of

the appliance (Fig 43) Item 6, and ensure

that the gasket and sealing rings are cor

rectly

fi tted.

IMPORTANT:

Make sure that the fl ue header

dia 60 mm duct is inserted fully into the fan spigot.

Summary of Contents for HE Primary AAA

Page 16: ...Supplied By www heating spares co Tel 0161 620 6677 17 Fig 18...

Page 31: ...Supplied By www heating spares co Tel 0161 620 6677 Fig 58 32 Fig 56 Fig 57...

Page 33: ...Supplied By www heating spares co Tel 0161 620 6677 34 Fig 60 Fig 61 Fig 62 Fig 63...

Page 42: ...Supplied By www heating spares co Tel 0161 620 6677 section 10 EXPLODED PARTS DIAGRAM 43...